Medical device

A technology of medical equipment and clamping device, which is applied in the direction of ceramic molding machine, ceramic extrusion die, manufacturing tools, etc., can solve the problems of low production efficiency and achieve the effects of improving productivity, ensuring quality, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

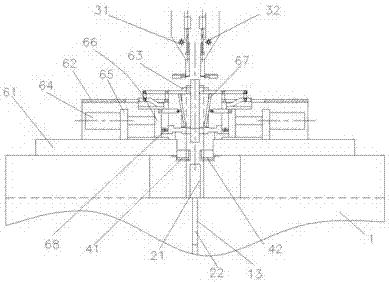

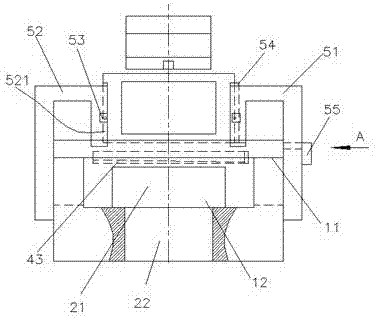

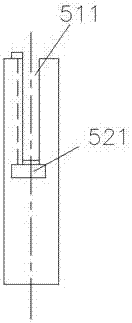

[0035] like Figure 1-Figure 14 As shown, a medical device of the present invention includes a clamping device, a pressing device, a discharge device, a retracting device, a second discharge device and a shell 1, and the shell 1 is provided with an upward U side groove with a notch, The second discharge device is installed in the U side groove, and the front and rear sides of the upper surface of the shell 1 are respectively provided with a guide rail 11 in the left and right directions. The pressing devices have two groups with the same structure, the left pressing device and the right pressing device. The pressing device is respectively installed on the guide rails 11 on the left and right sides of the upper surface of the shell 1 and can slide left and right along the guide rails 11, and the center of the upper surface of the shell 1 is provided with an access groove 12 in the front and rear directions, A sliding hole 13 in the up-and-down direction is provided in the acces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com