Patents

Literature

42results about How to "Close enough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and related device for controlling radiation fresh-air conditioning systems

ActiveCN105509259AAdequate controlRunning adequatelyMechanical apparatusSpace heating and ventilation safety systemsFresh airEngineering

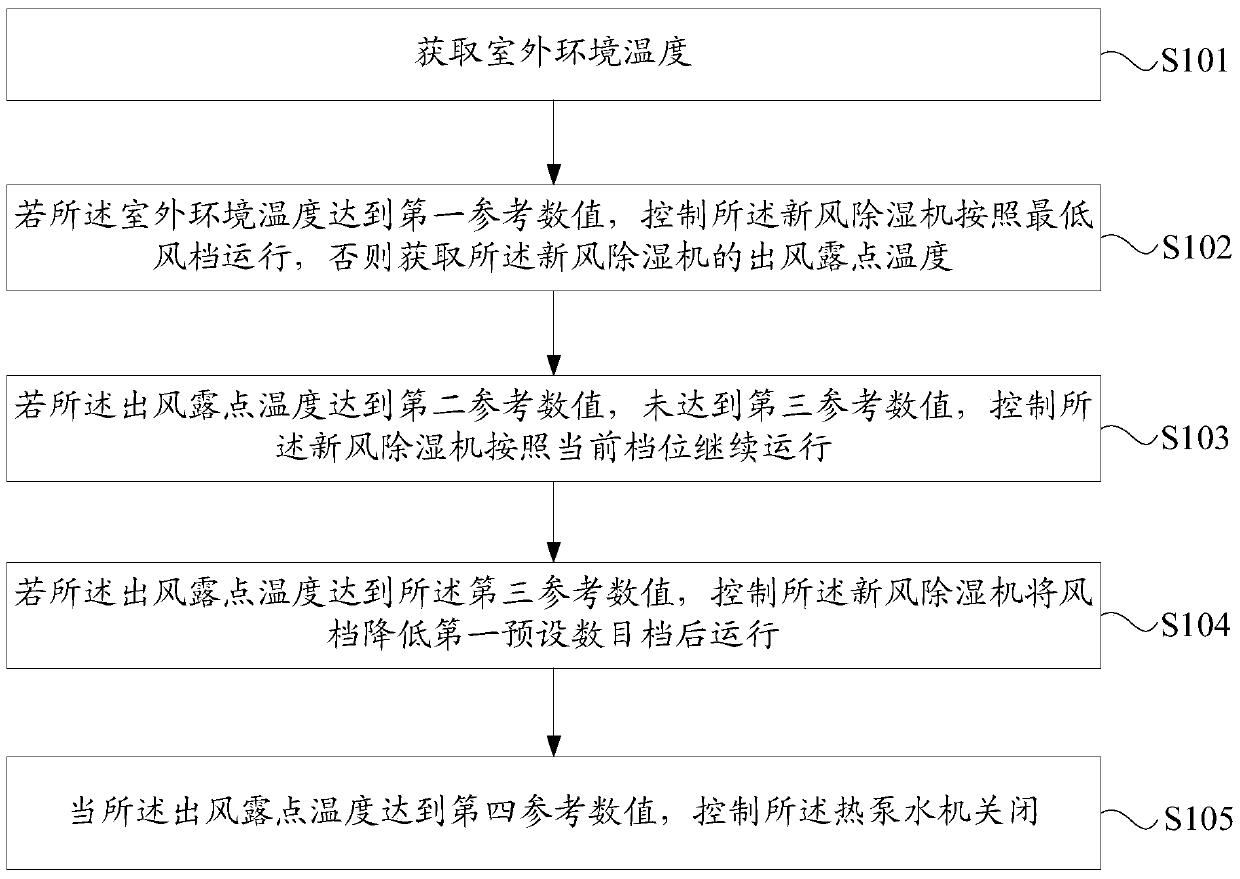

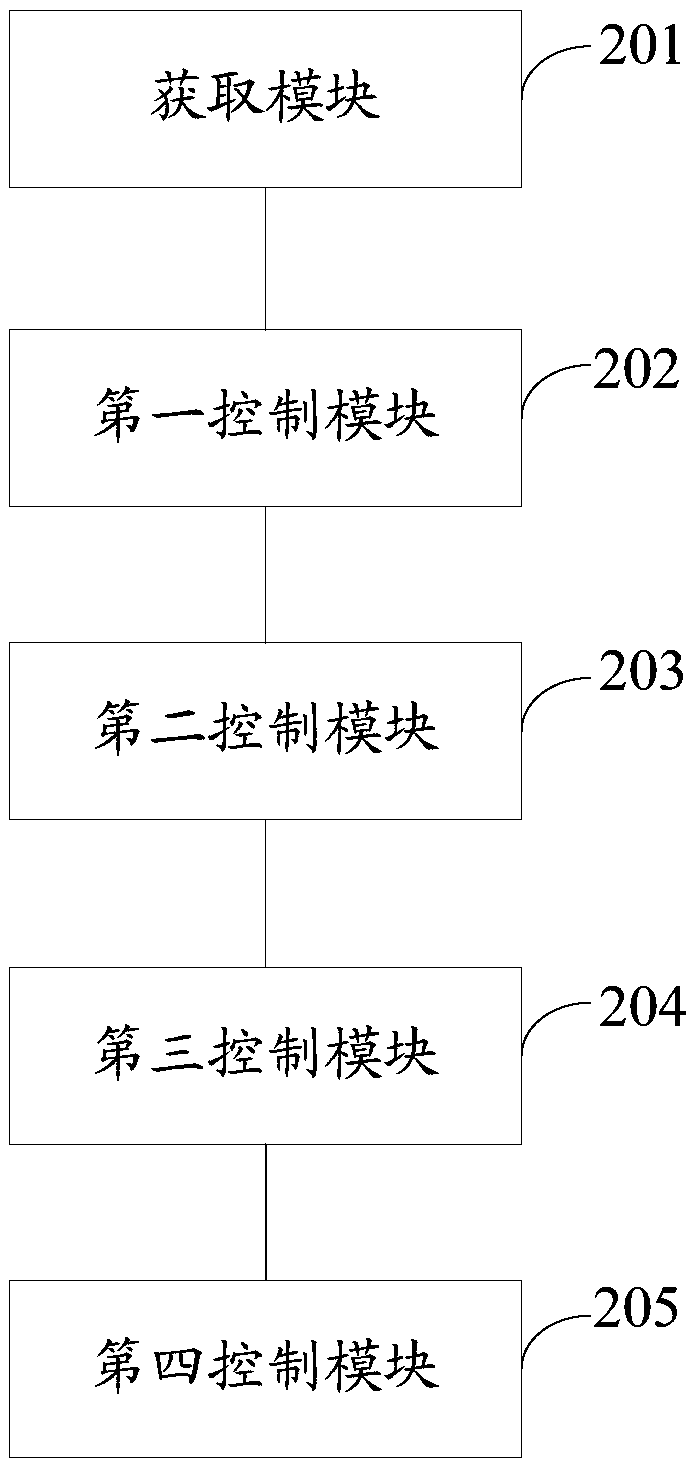

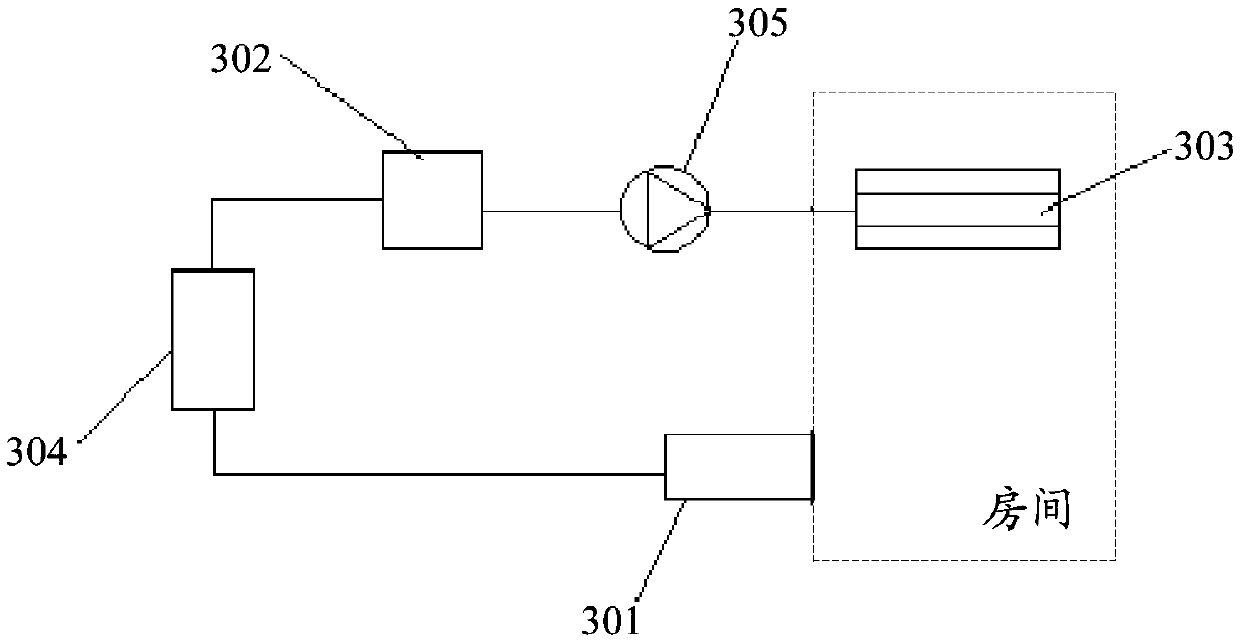

The invention discloses a method and a related device for controlling radiation fresh-air conditioning systems. The method includes acquiring outdoor environmental temperatures; enabling fresh-air dehumidifiers to run according to the lowermost air grades under the control if the outdoor environmental temperatures reach first reference values, or acquiring air outlet dew-point temperatures of the fresh-air dehumidifiers if the outdoor environmental temperatures do not reach first reference values; enabling the fresh-air dehumidifiers to continue running according to current grades under the control if the air outlet dew-point temperatures reach second reference values but do not reach third reference values; lowering the air grades by a first preset number if the air outlet dew-point temperatures reach the third reference values, and then enabling the fresh-air dehumidifiers to run under the control; turning off heat pump water machines under the control when the air outlet dew-point temperatures reach fourth reference values. According to the technical scheme, the method and the related device have the advantages that turning-off frequencies of the heat pump water machines and water valves can be effectively reduced on the basis that condensation generated on the surfaces of radiation tail ends is effectively prevented, accordingly, the radiation fresh-air conditioning systems have sufficient refrigerating capacity, and the comfort can be improved for people in rooms.

Owner:GREE ELECTRIC APPLIANCES INC

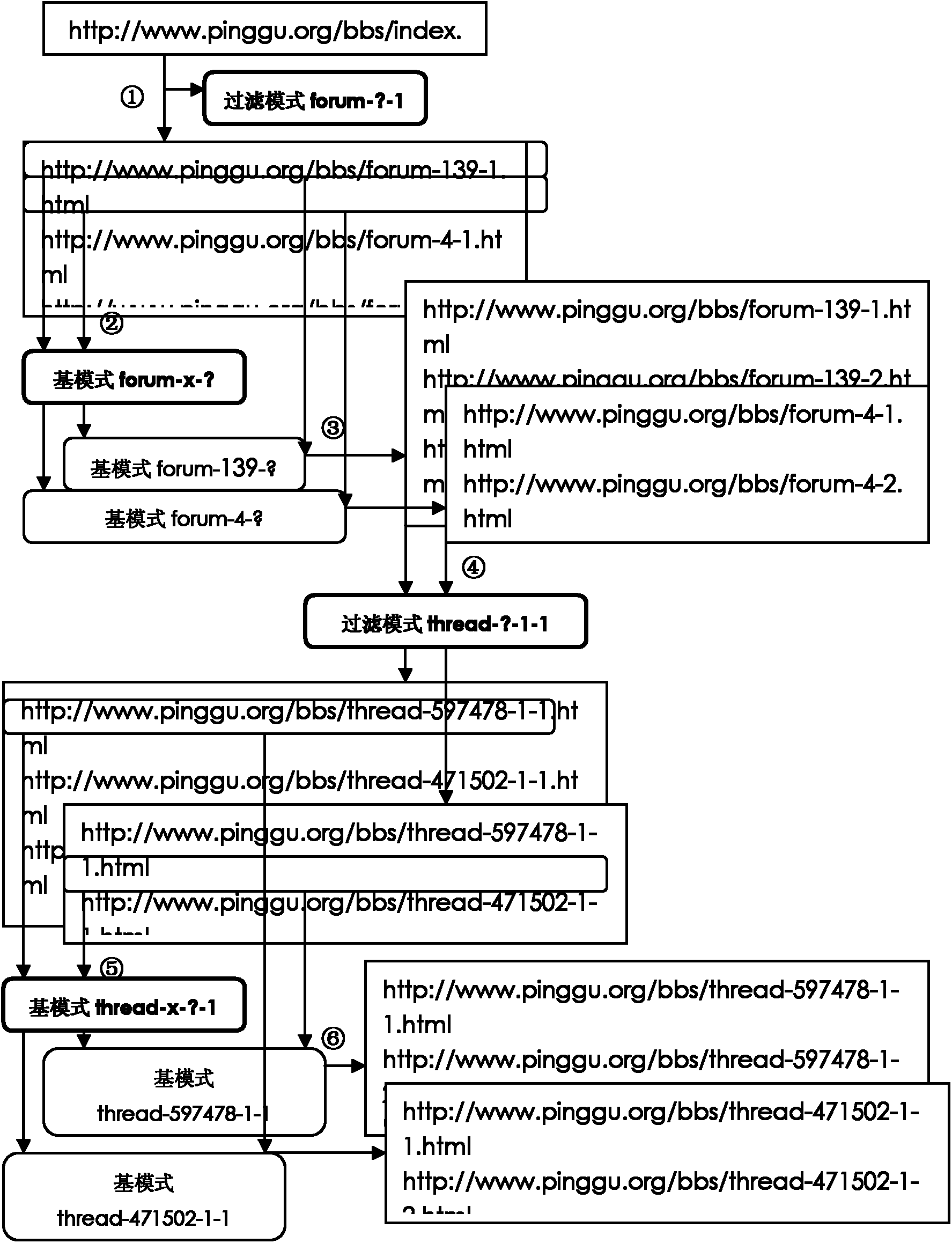

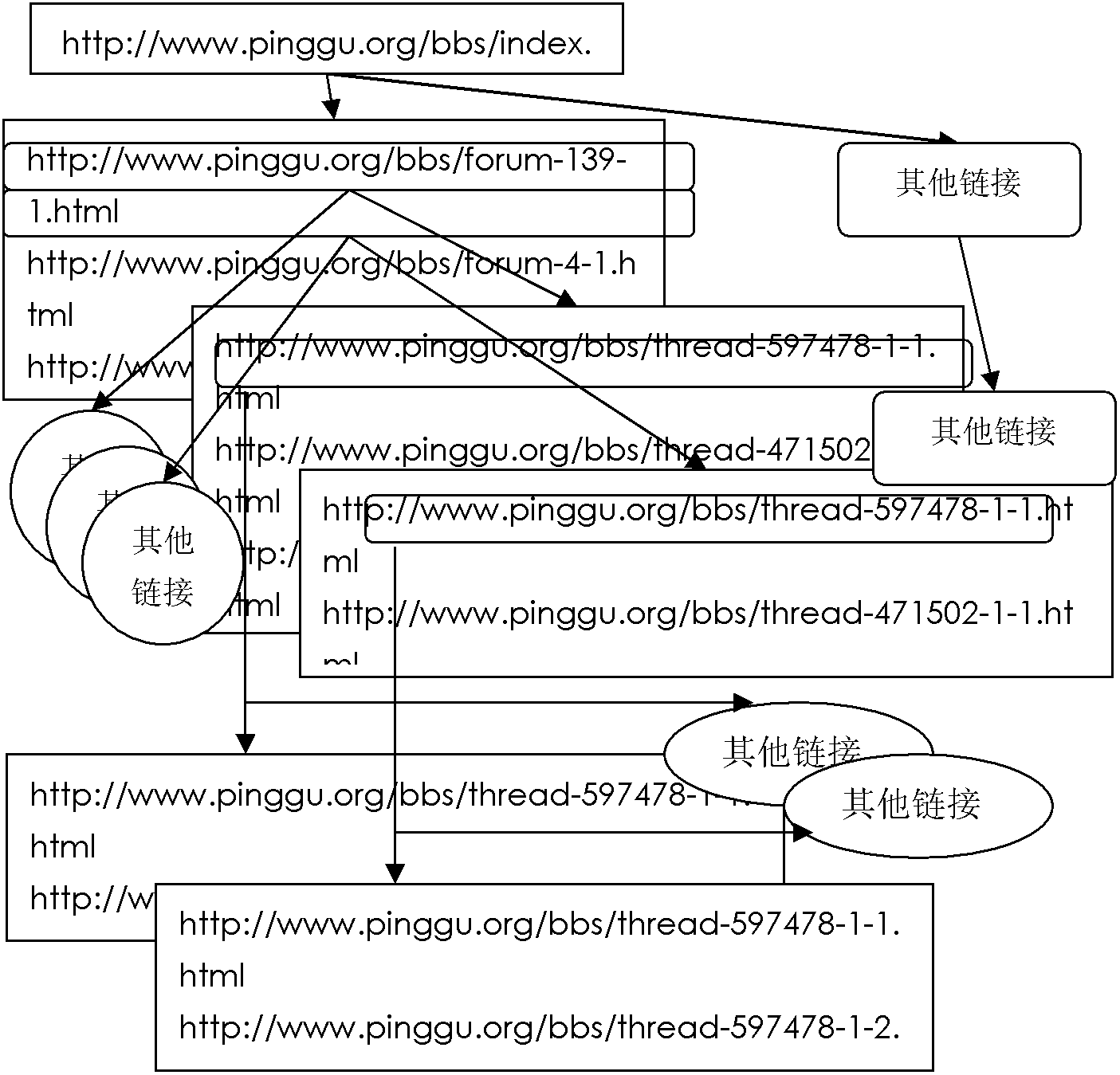

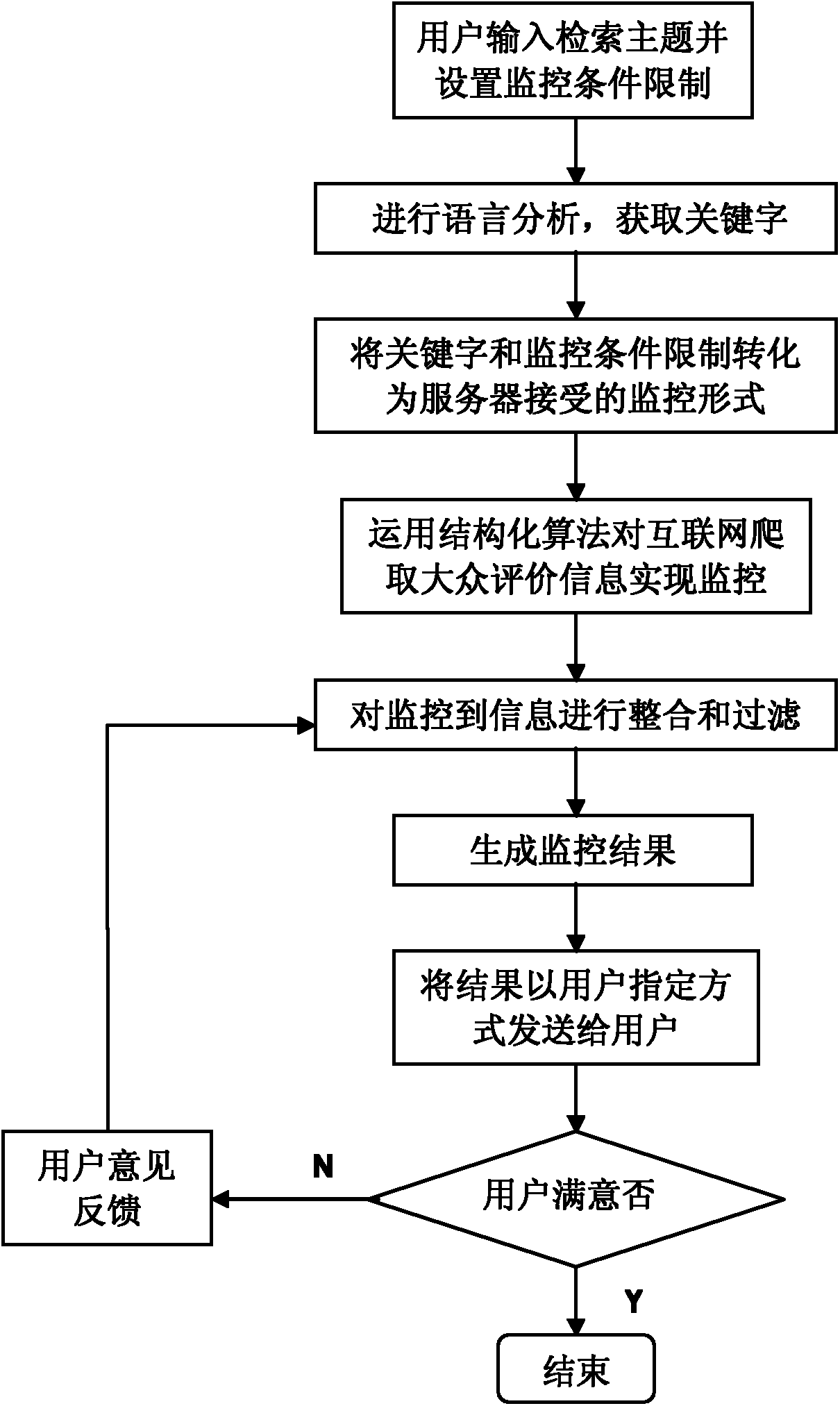

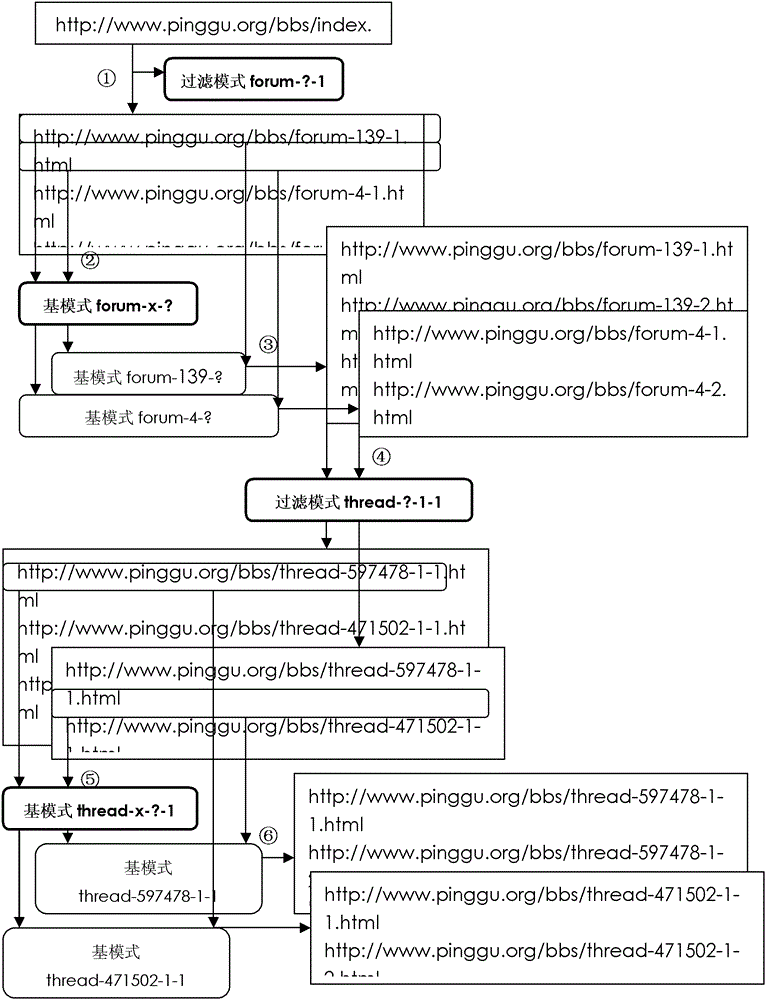

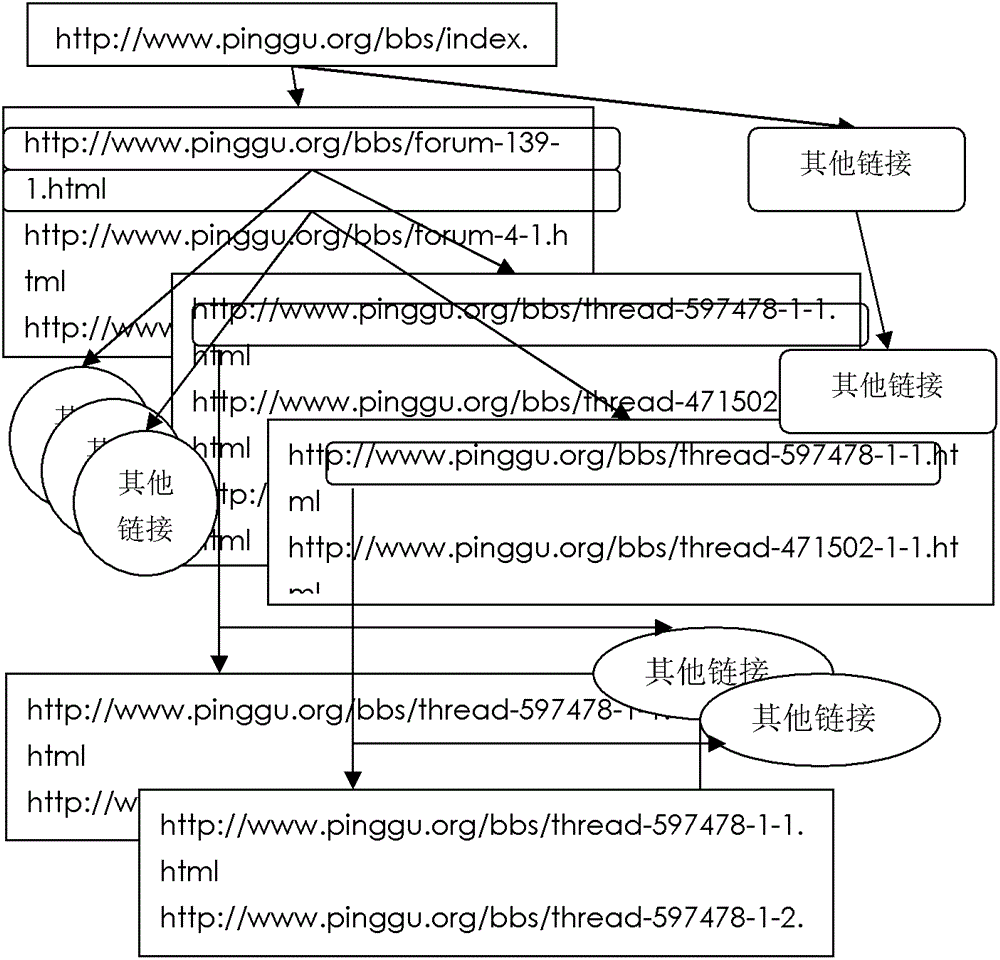

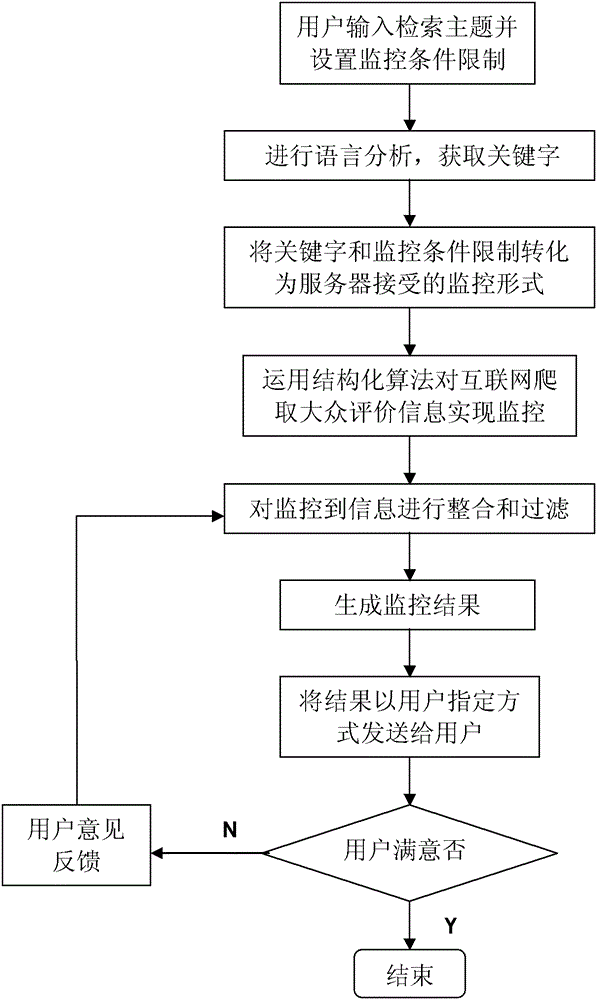

Automatic public opinion monitoring method based on internet hierarchical structure storage

ActiveCN102214227ARealize monitoringAccurate expressionTransmissionSpecial data processing applicationsPersonalizationThe Internet

The invention provides an automatic public opinion monitoring method based on internet hierarchical structure storage. The method comprises the following steps that: a user uploads a monitoring request; and a server analyzes the monitoring request, acquires acceptable monitoring conditions of the server, realizes monitoring the internet by using a hierarchical structure storage monitoring method,filters and integrates public assessment information relevant to a subject request of the user by using a regular expression technology to generate a personalized monitoring result, and sends the personalized monitoring result to the user by various modes. By the method, a machine can intelligently perform semantic analysis on a monitoring subject which is submitted by the user, the monitoring ofa subject which most meets a monitoring requirement of the user on the internet and the relevant public assessment information is realized, the monitoring result is automatically generated by centering on the subject, and a user can request the style and form of the generated monitoring result and make a mode of acquiring the monitoring result. Therefore, the monitoring process is more personalized, more convenient, more abundant and more vivid.

Owner:SOUTH CHINA UNIV OF TECH

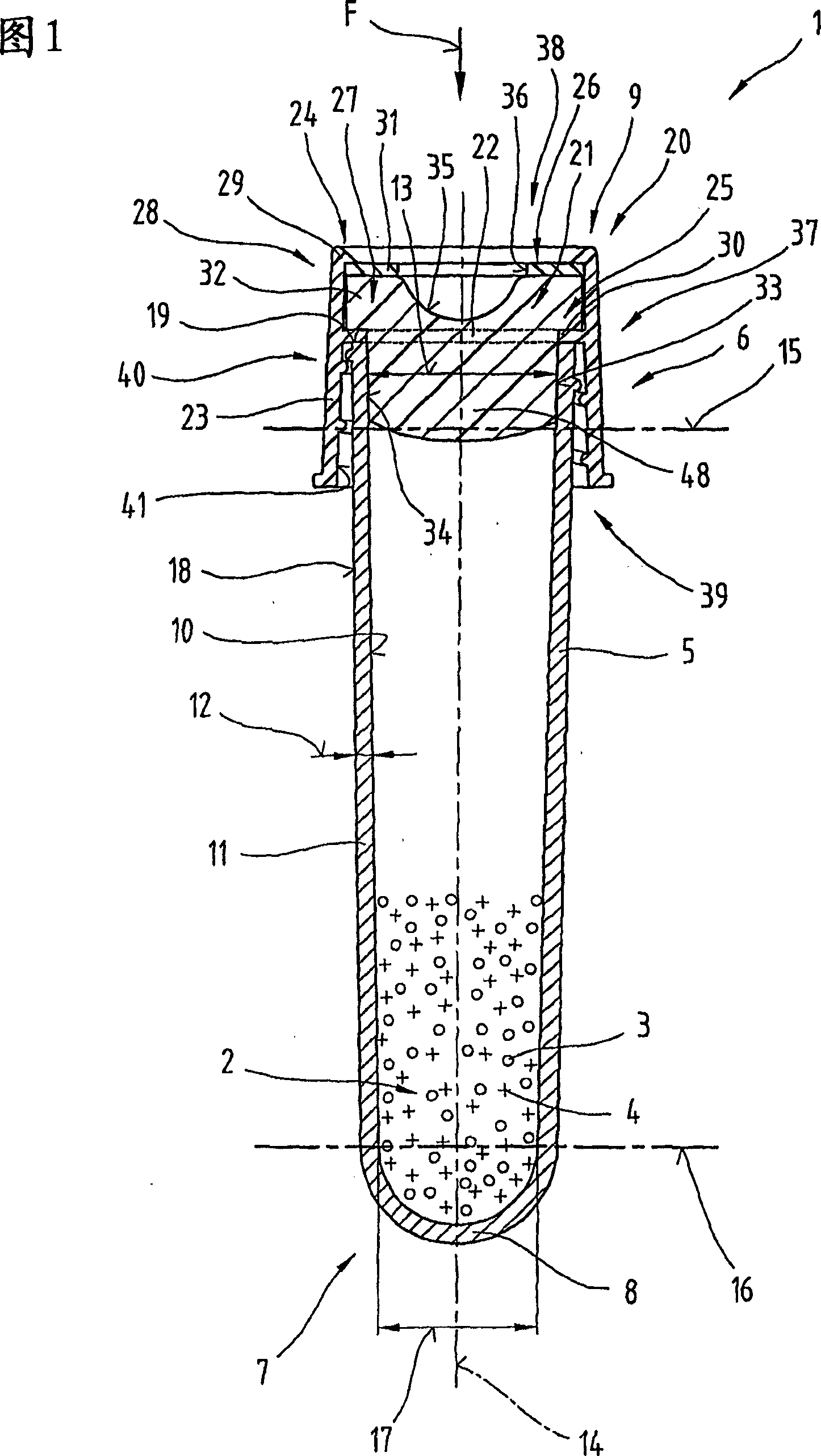

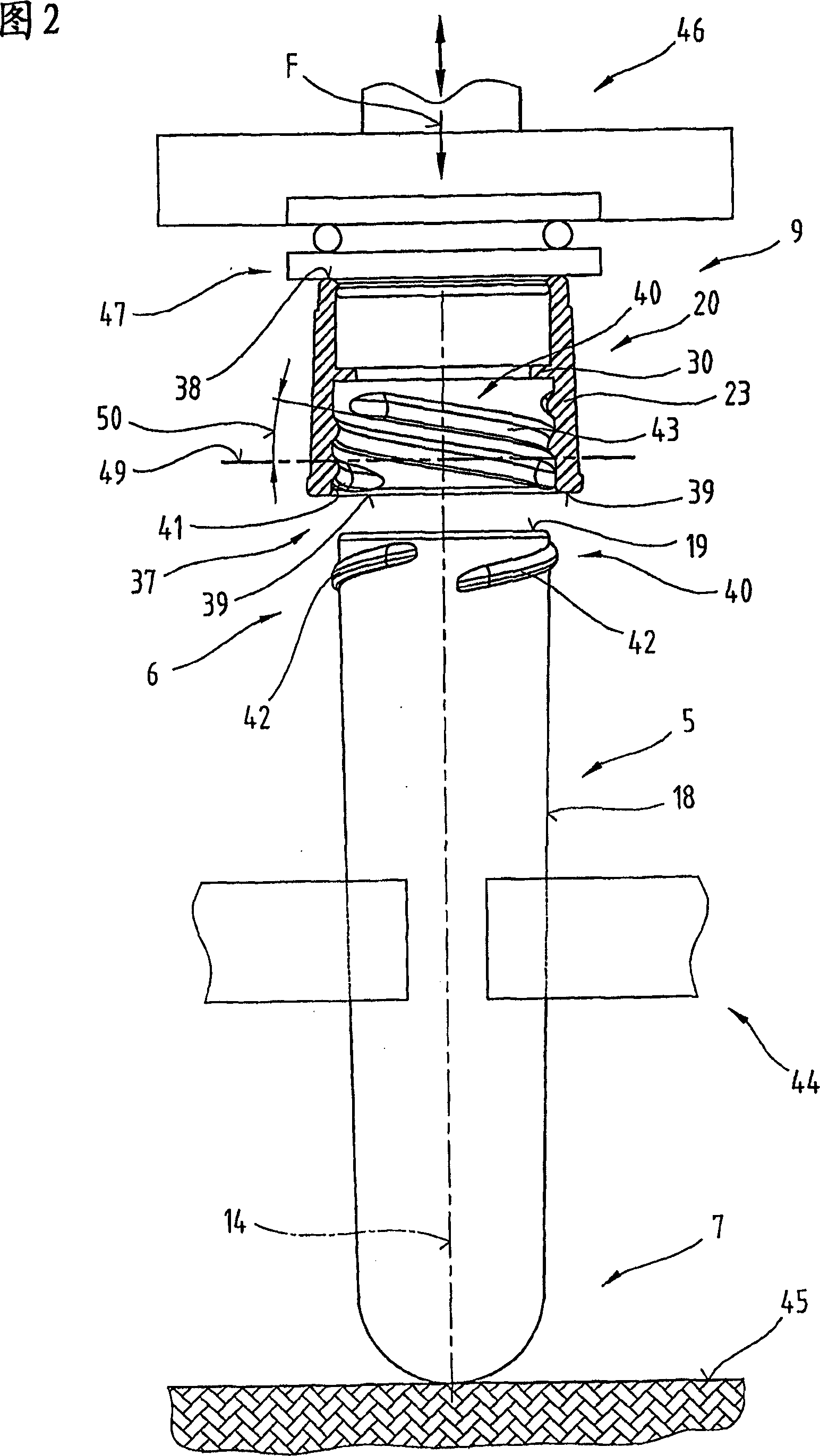

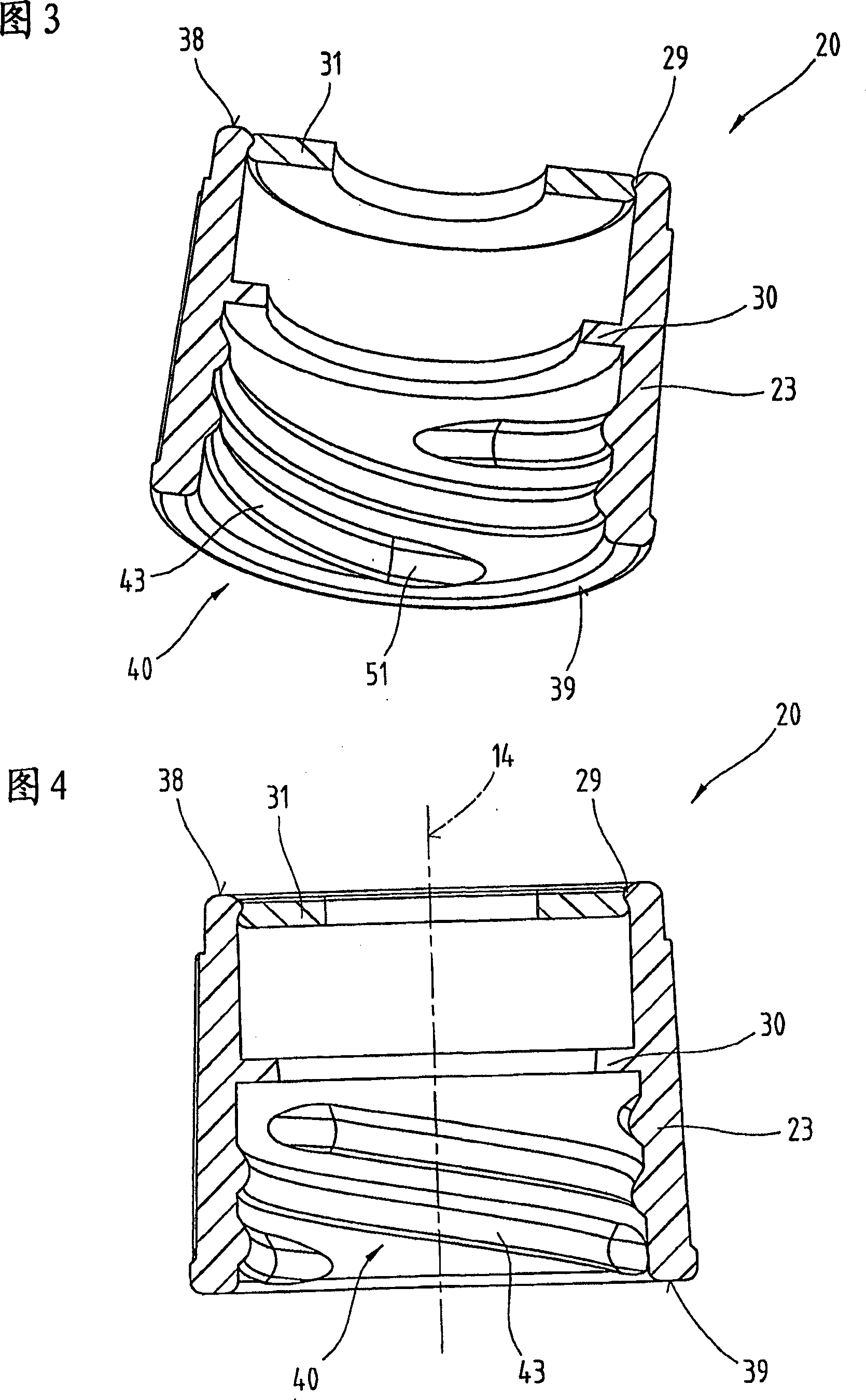

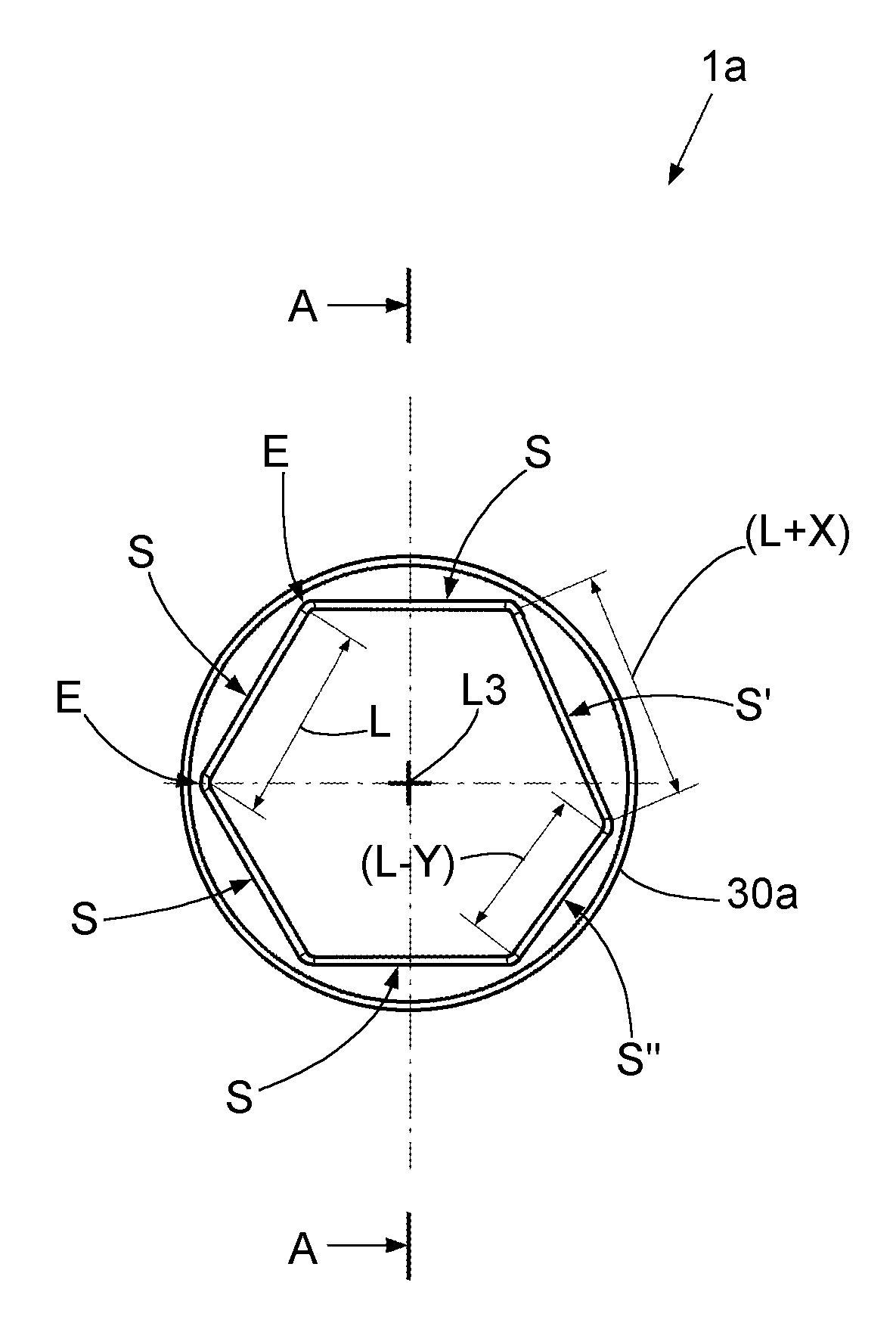

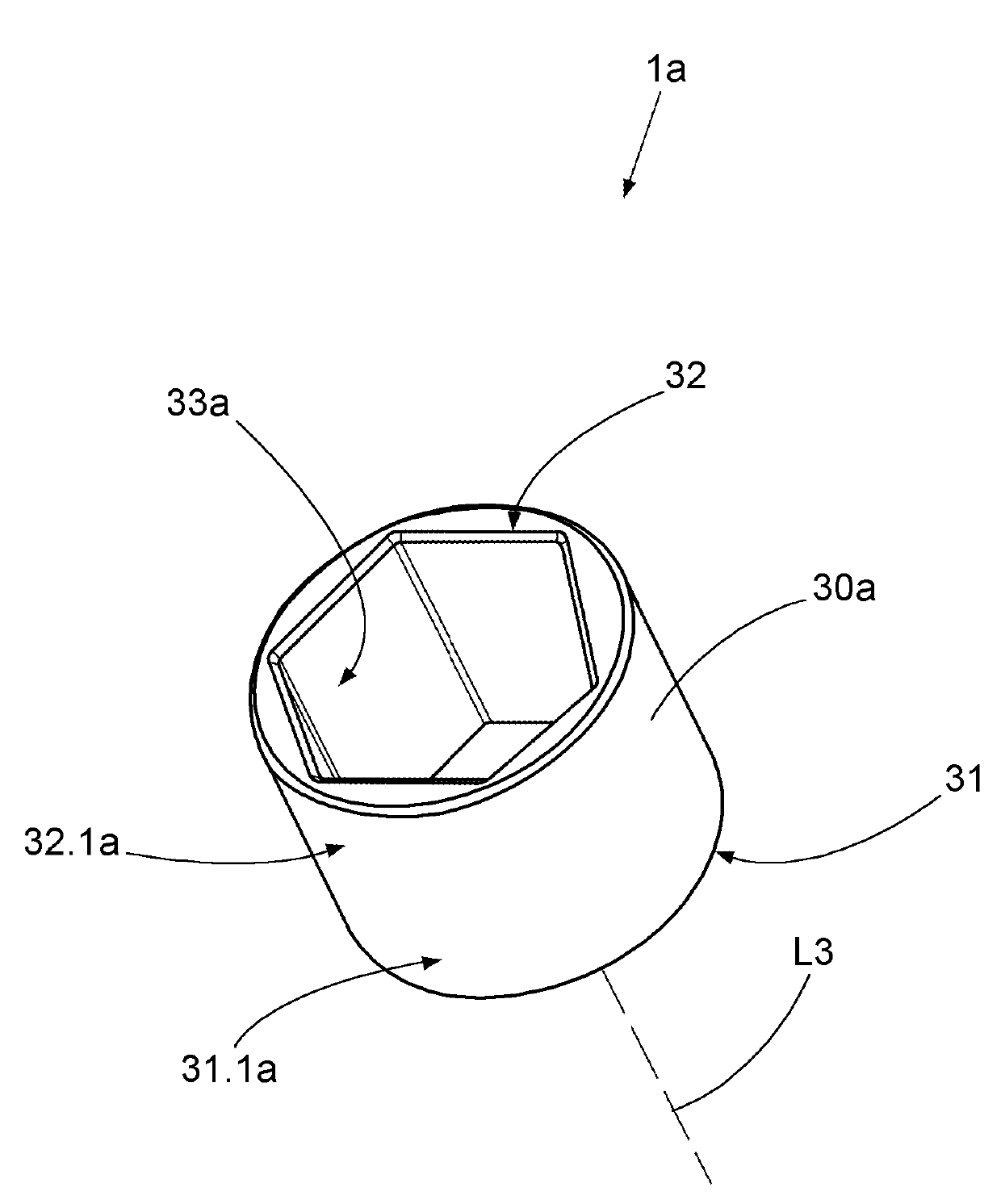

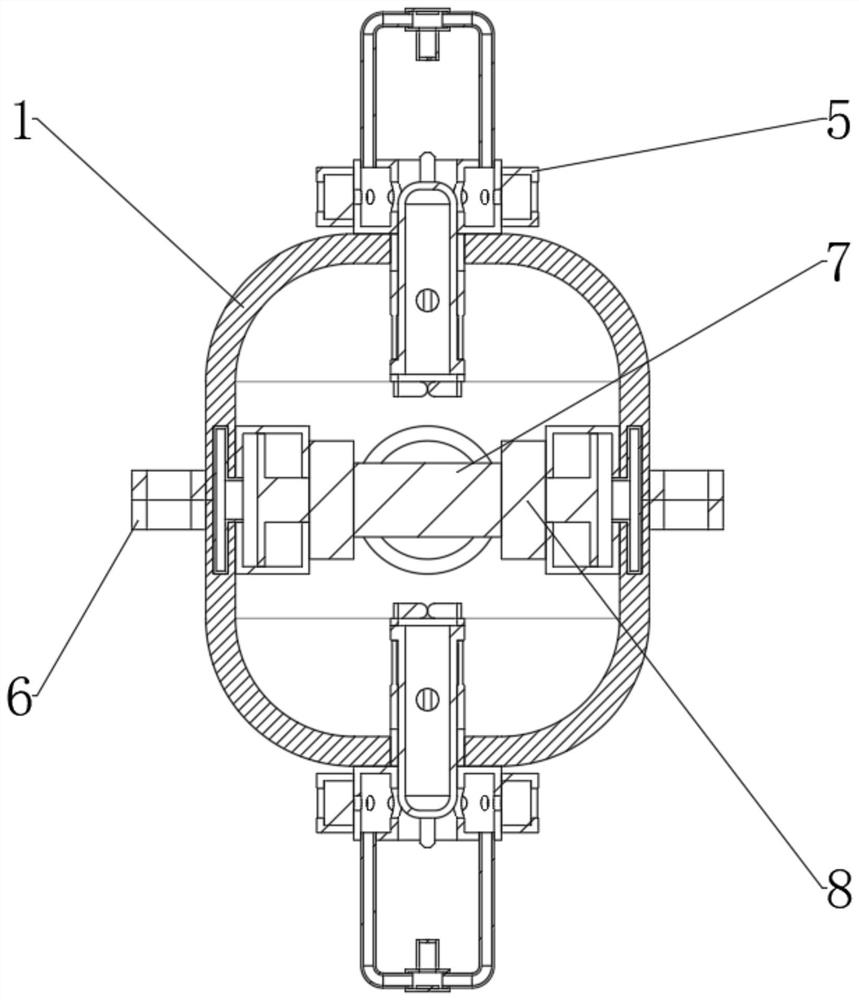

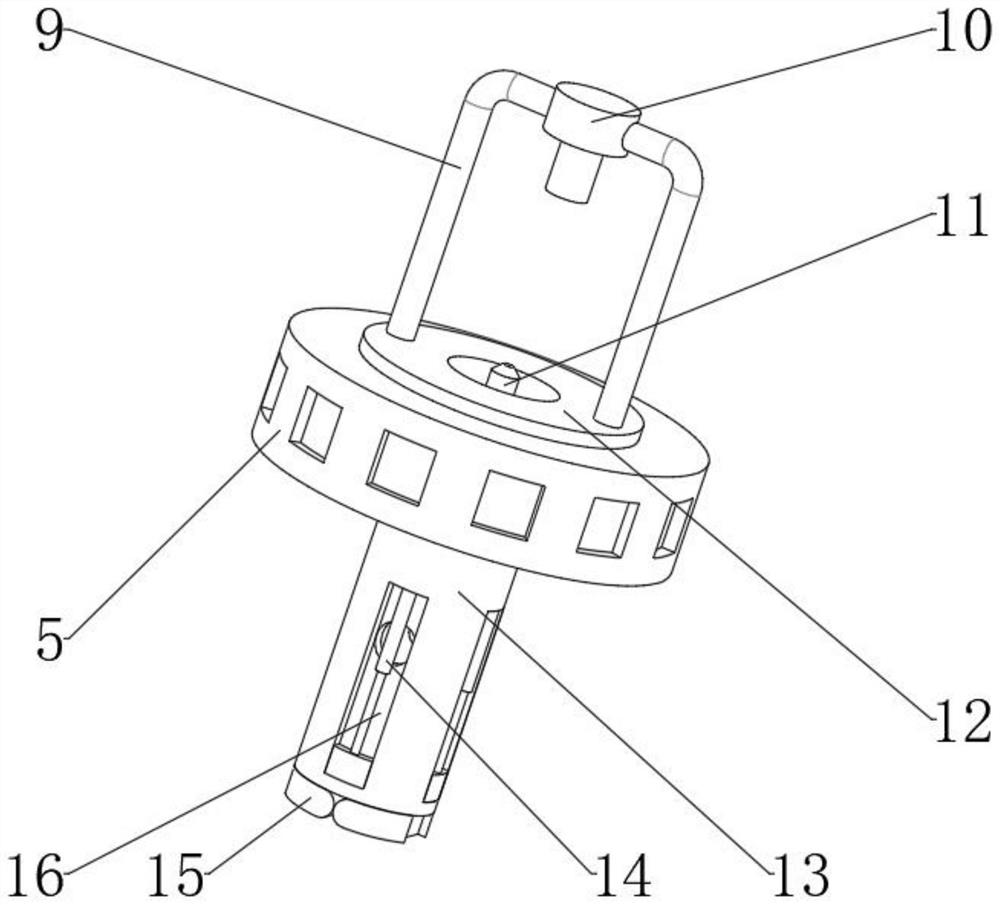

Method for the assembly of a cap with a receptacle

ActiveCN1997455AAvoid blockingClose enoughCapsThreaded caps applicationRelative displacementEngineering

The invention relates to a method for the assembly of a cap (20) of a sealing device (9) with an open end (6, 7) of a receptacle (5), to form a storage device (1) for bodily fluids, tissue parts, or tissue cultures, whereby a relative turning or pivoting motion between the cap (20) and the receptacle (5) is carried out about a common longitudinal axis (14). The relative displacement is carried out by exerting a pressure force (F) on at least one of the assembly components, approximately in the direction of the longitudinal axis (14). The invention further relates to a cap (20) to form the sealing device (9), a receptacle (5) and a storage device (1) formed therefrom, comprising at least the cap (20), a sealing device (21) retained therein and the receptacle (5).

Owner:GREINER BIO ONE GMBH

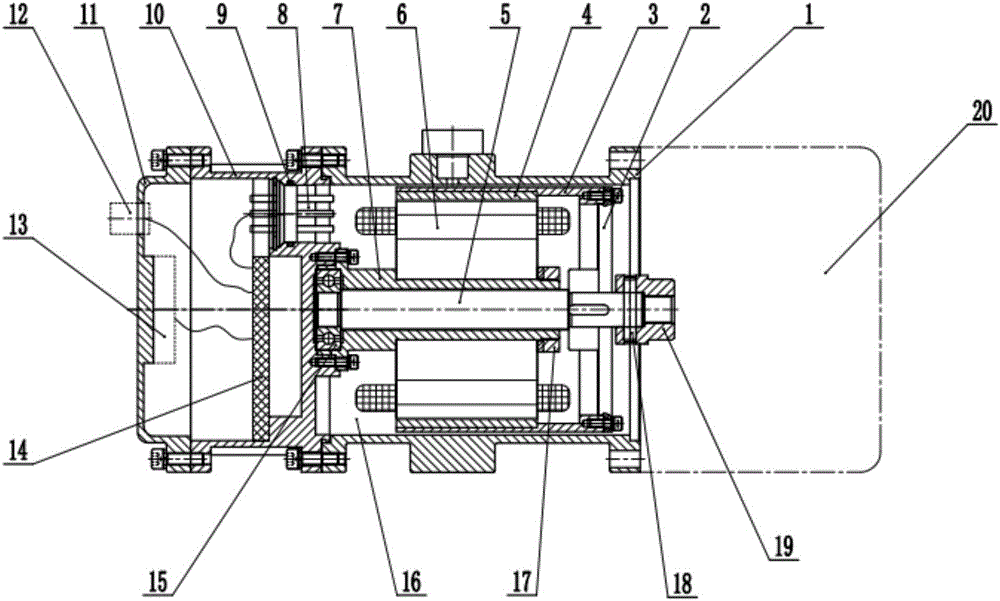

Electric automobile air conditioner compressor drive DC brushless motor

ActiveCN106059147AImprove running smoothnessNot easy to fall offAssociation with control/drive circuitsMagnetic circuit rotating partsBrushless motorsRotor magnets

The invention relates to the technical field of automobiles, and particularly relates to an electric automobile air conditioner compressor drive DC brushless motor. The motor comprises a motor body, a stator assembly, a stator sleeve, a rotor assembly, a motor shaft, and a back cover assembly. The rotor assembly comprises permanent magnet bars, a rotor drum, and a rotor end cover. The permanent magnet bars are ring-shaped, and are fixed to the inner side of the rotor drum. The rotor drum and the rotor end cover are fixedly connected. The rotor end cover is fixedly connected with the motor shaft through a key. The stator sleeve is fixedly connected with a back end cover. The stator assembly is fixed to the stator sleeve. The stator sleeve movably sleeves the motor shaft. The back cover assembly is equipped with a controller inside. The rotor magnet steel of the motor is not easy to fall off, and can be close enough to the stator, so the efficiency of magnetic action is improved. Moreover, the torque is increased, the number of permanent magnets is increased, and the running stability of the rotor is improved. The motor is convenient to install and easy to match, and the sales thereof is promoted.

Owner:FENGHUA XINGYU SPECIAL MOTOR MFG

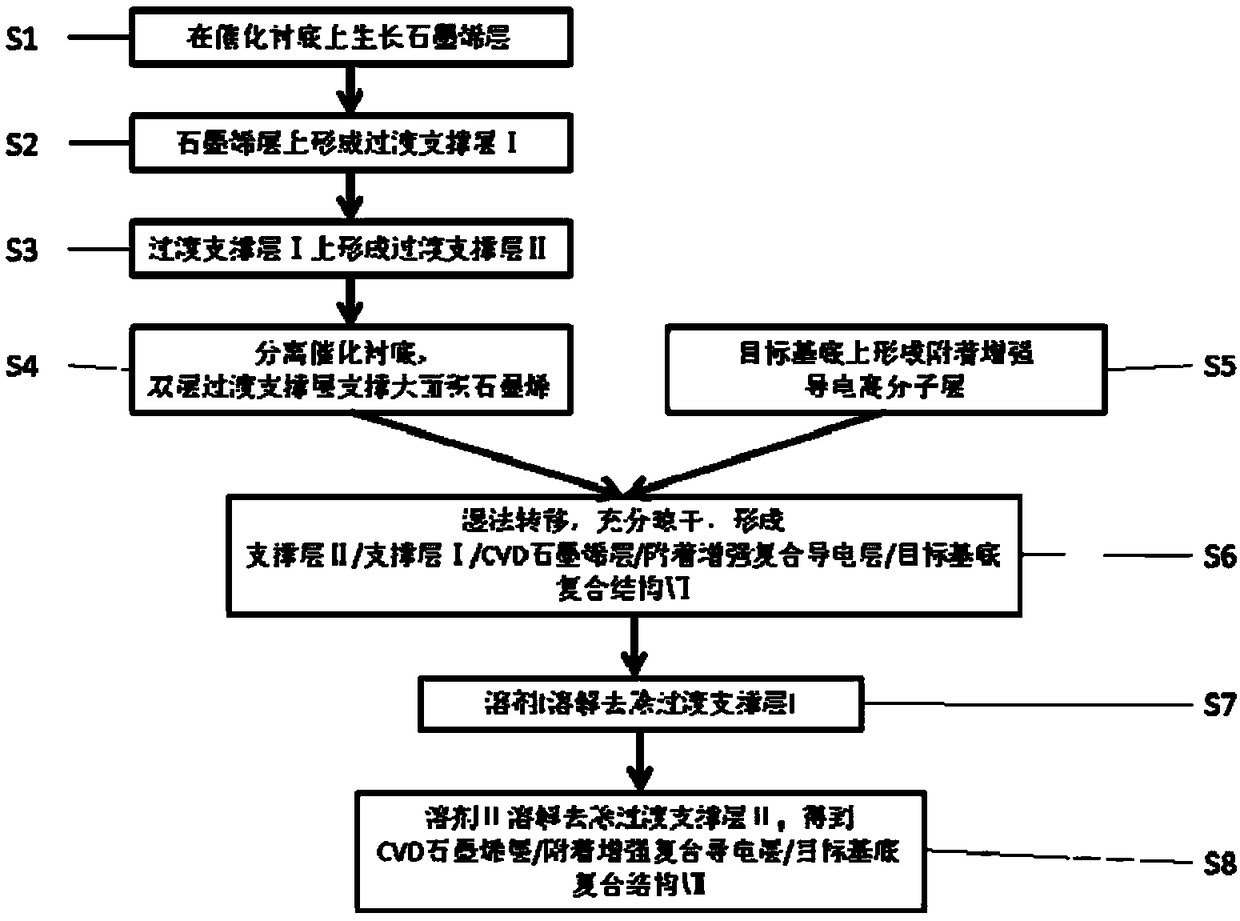

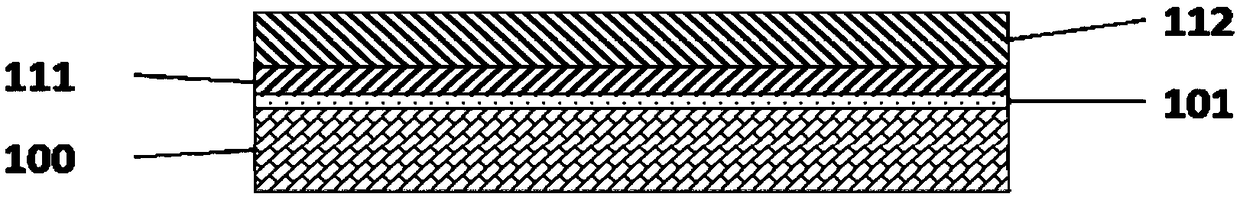

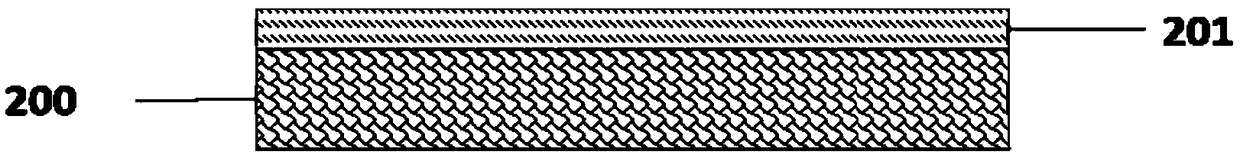

Graphene adhesion-enhanced composite conductive structure and preparation method thereof

ActiveCN108648853ARealize large area clean and non-destructive transferGood adhesionConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersConductive polymerNanotechnology

The invention discloses a graphene adhesion-enhanced composite conductive structure capable of realizing the enhanced adhesion of graphene to a target substrate, and a preparation method thereof. Thegraphene adhesion-enhanced composite conductive structure comprises a CVD graphene layer, a conductive polymer layer, and a target substrate arranged from top down. The preparation method comprises the steps of: S1, generating a graphene layer on the catalytic substrate; S2, coating a thermoplastic resin I on the surface of the grapheme to form a transition support layer I; S3, continuing to coata thermoplastic resin II on the surface to form a transition support layer II; S4, separating the catalytic substrate to obtain a structure IV; S5, coating the conducting polymer on the target substrate to obtain a structure V; S6, dragging a structure IV from the structure IV from water by the wet process; S7, removing the transition support layer II; and S8, removing the transition support layerI, thereby obtaining the composite structure VII. The graphene adhesion-enhanced composite conductive structure and the preparation method thereof are used to keep the graphene intact and not damaged, and the complete transfer preparation of the large-area graphene may be realized.

Owner:CHONGQING GRAPHENE TECH

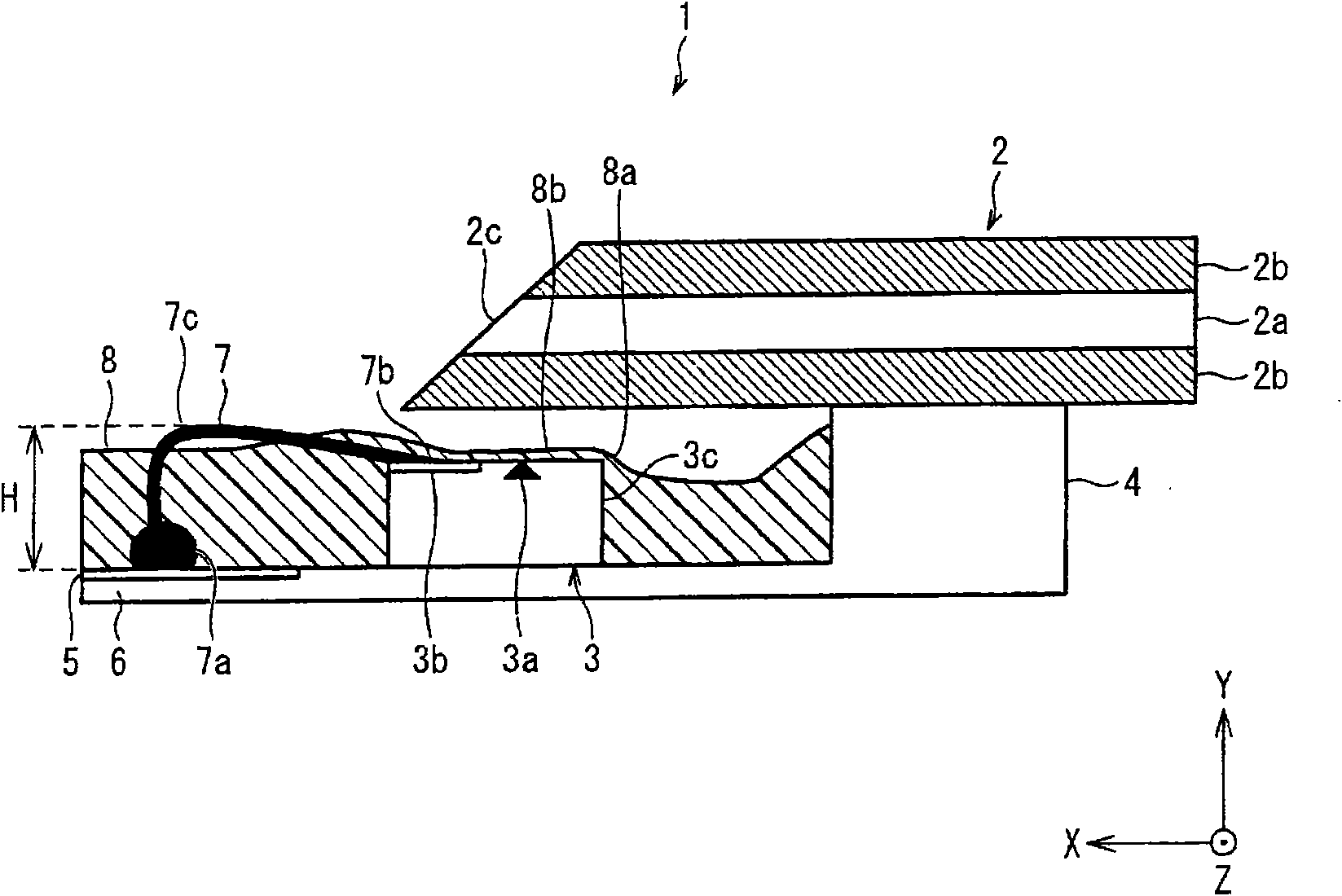

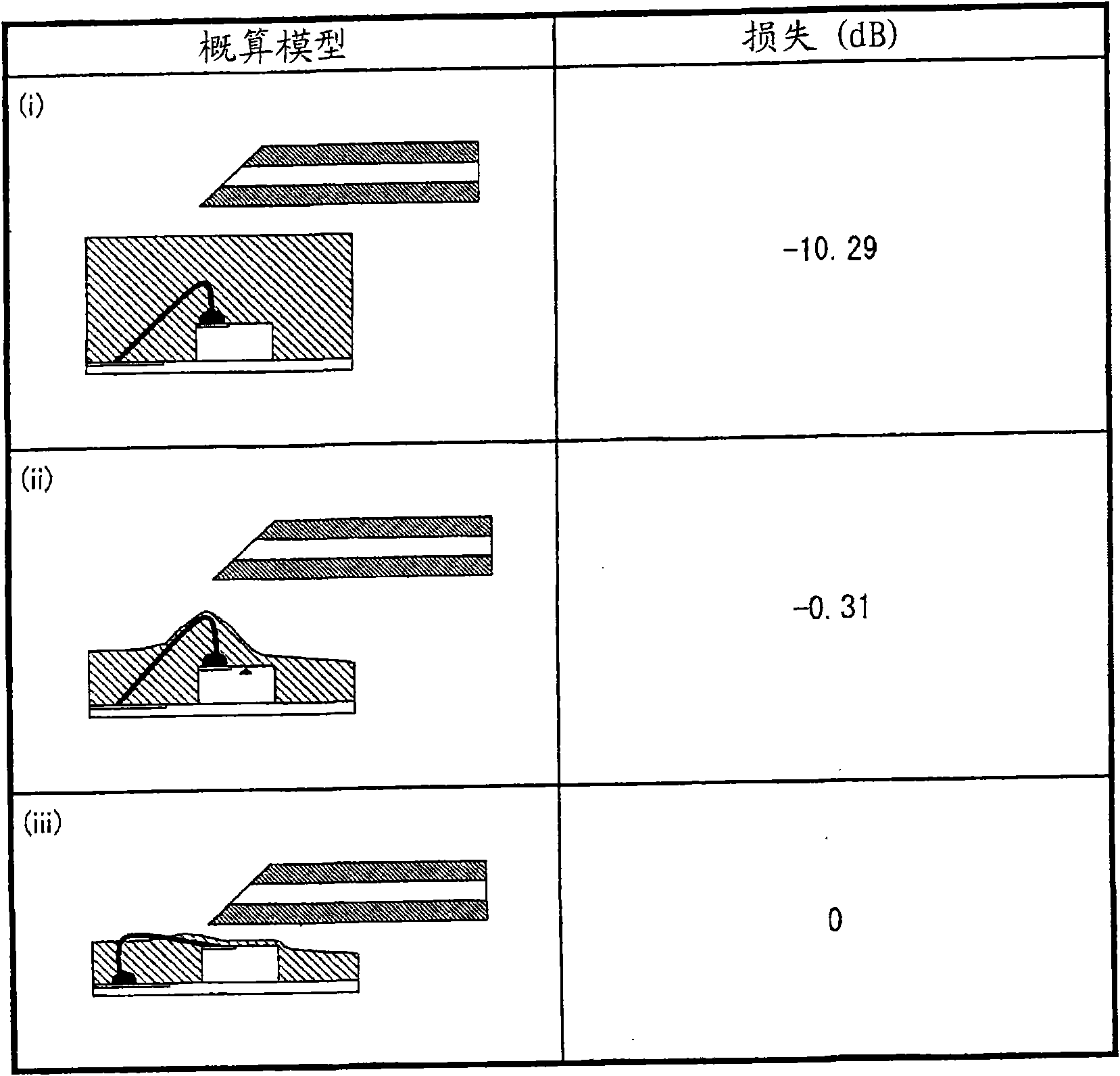

Light transmission module, electronic device, and manufacturing method of light transmission module

InactiveCN101819302AClose enoughLight coupling loss is smallSolid-state devicesCoupling light guidesCoupling lossOpto electronic

A light transmission module, an electronic device, and a manufacturing method of the light transmission module reduces the distance between a light guide and a light emitting and receiving element and inhibits the light coupling loss between the light guide and the light emitting and receiving element. The light transmission module has a light transmission path for transmitting light, an optical element including a light emitting and receiving surface for emitting or receiving an optical signal transmitted by the light transmission path, and having a light emitting and receiving point with a function of photoelectric conversion and an electrode pad formed on the light emitting and receiving surface, a substrate mounted with the optical element and an electrical wiring, a bonding wiring for electrically connecting the electrode pad and the electrical wiring, and a sealing portion for sealing the optical element. The electrical wiring and the electrode pad are reverse wire-bonded by the bonding wiring. The sealing portion includes an inclined part where a liquid sealing resin material is raised and solidified along a side wall of the optical element by surface tension, and a flat part where the liquid sealing resin material is spread in parallel and solidified along the light emitting and receiving surface, the inclined part and the flat part being coupled.

Owner:ORMON CORP

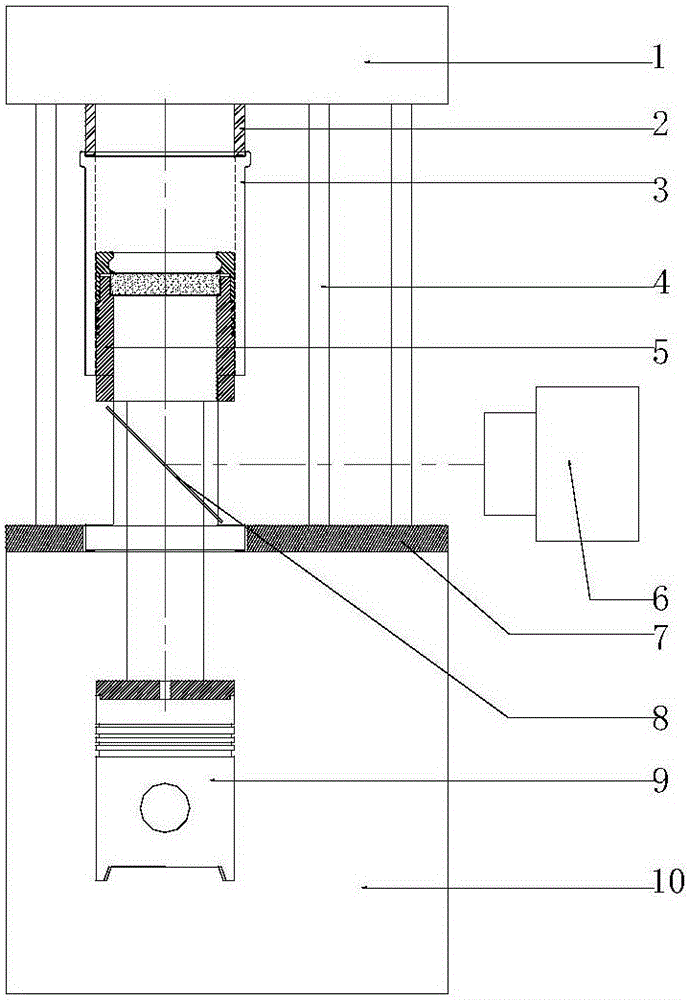

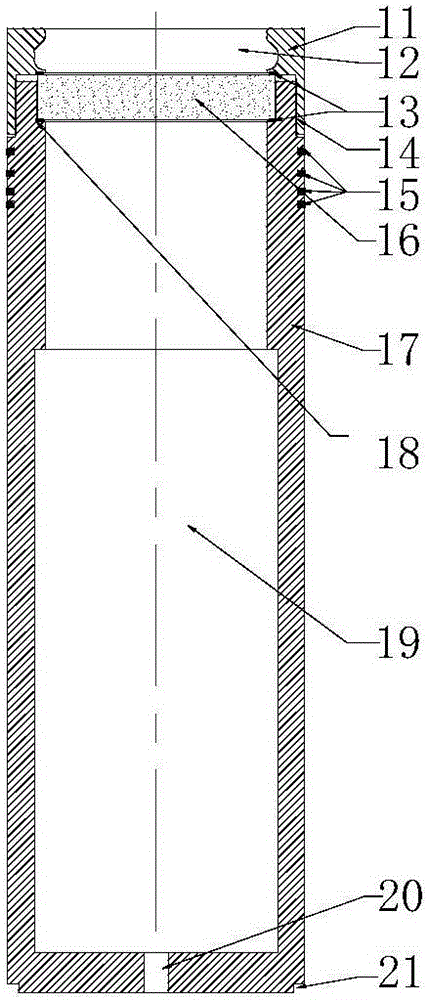

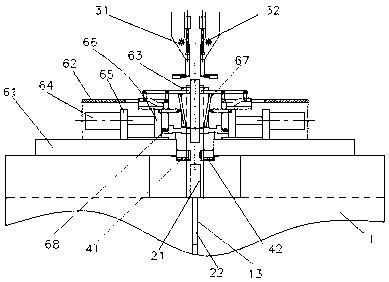

Lengthened piston mechanism for visual optical engine device

InactiveCN106089479AClose enoughSolve the sealing problemSealing arrangements for enginesMachines/enginesPiston ringGraphite

The invention aims to provide a lengthened piston mechanism for a visual optical engine device. The lengthened piston mechanism for the visual optical engine device comprises a cylinder cover, a lengthened piston, an original piston and a cylinder body. A lower cover plate is fixed to the cylinder body. A lengthened supporting column is supported between the cylinder cover and the lower cover plate. A quartz cylinder jacket and a metal cylinder jacket are arranged below the cylinder cover in sequence. The upper end of the lengthened piston is located in the metal cylinder jacket, and the lower end of the lengthened piston is connected with the original piston. According to the lengthened piston mechanism for the visual optical engine device, the piston cover and a main part of the lengthened piston are connected through a thread structure, the pretightening force of threaded connection makes the connection surface of the piston cover and a transparent window have sufficient tightness, the problems of poor sealing and air leakage between the transparent window and the pistons are solved, and the compression ratio can be changed by changing the thicknesses of sealing gaskets, so that the measurement requirements under different compression ratio conditions are met; and meanwhile, four gas rings are adopted, and a graphite coating is adopted for a piston ring so that abrasion of the cylinder jackets can be reduced, the portion between the gas rings and the cylinder body is coated with grease, and thus lubricating and sealing effects are achieved effectively.

Owner:HARBIN ENG UNIV

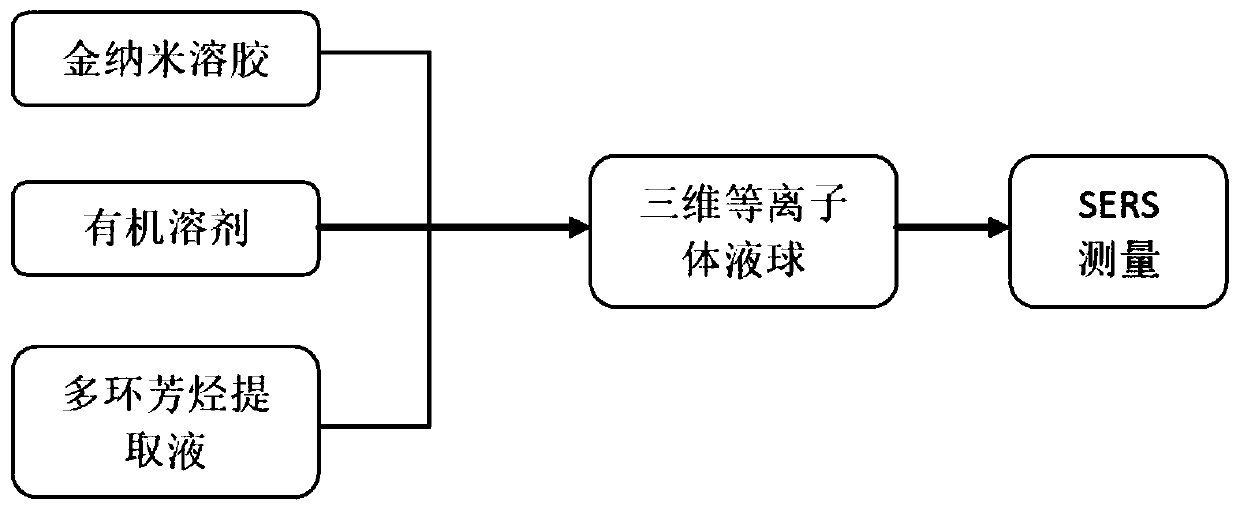

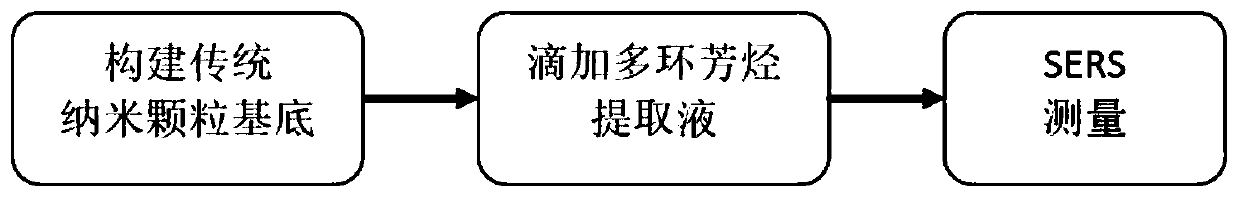

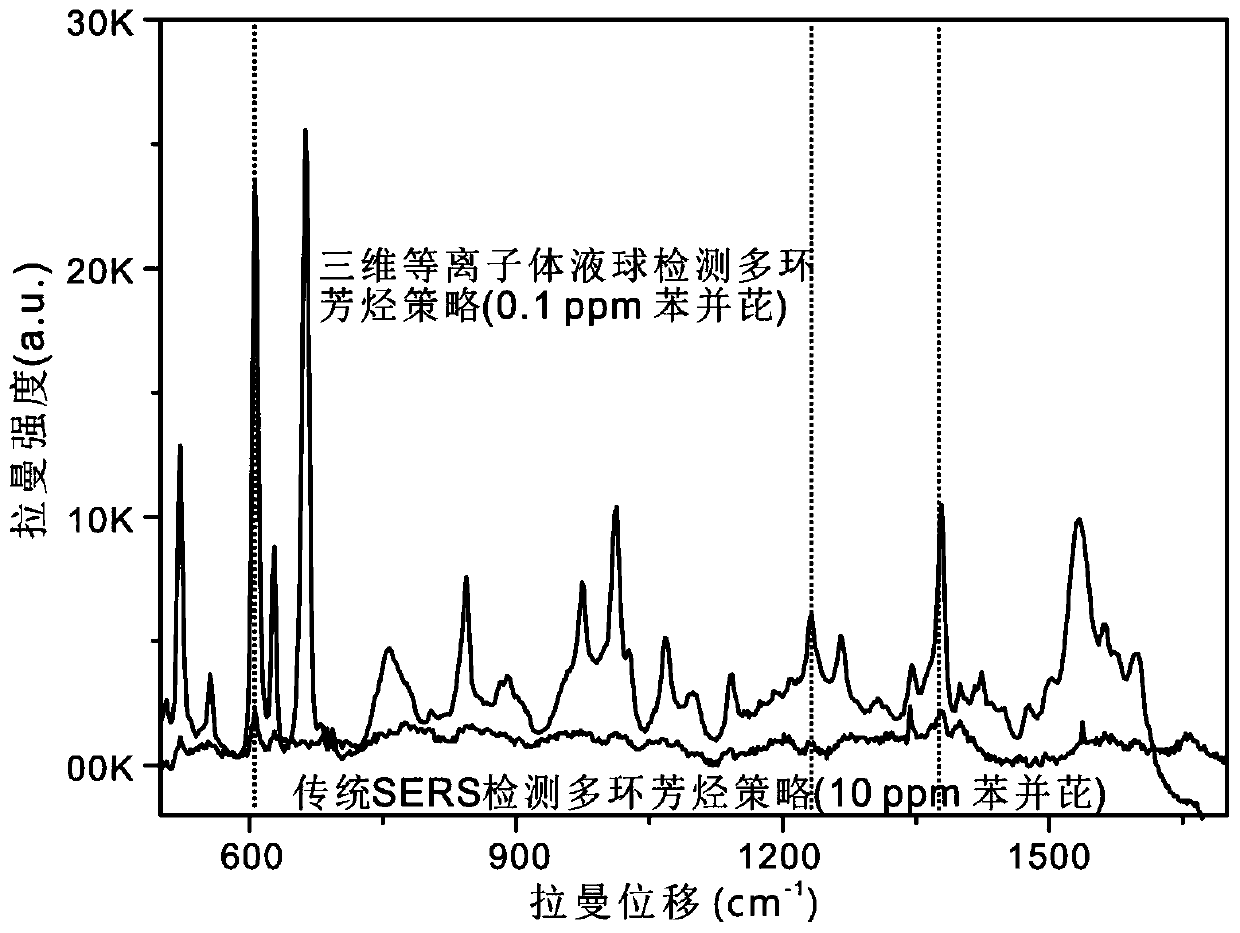

Detection method for polycyclic aromatic hydrocarbons in edible oil

ActiveCN109946284ALarge SERS EnhancementGood stability of SERSPreparing sample for investigationRaman scatteringChemistryEdible oil

The invention discloses a detection method for polycyclic aromatic hydrocarbons in edible oil. The method comprises the following steps that the edible oil is added into an extractant, and layered after violent oscillation, and an extraction layer includes a polycyclic aromatic hydrocarbons extract; a precious metal nanometer sol is uniformly mixed with an organic solvent whose density is higher than that of water to form a mixed solution; the polycyclic aromatic hydrocarbons extract is added to the mixed solution, and shocked violently to form a 3D plasma liquid sphere; the above steps are repeated, part volume is removed from the total organic phase slowly by sucking, and the 3D plasma liquid sphere is condensed in-situ; and Raman detection is carried out on the 3D plasma liquid sphere after in-situ condensation. According to the detection method, polycyclic aromatic hydrocarbons can be detected needless of modifying a nanometer material, the method is simple and convenient in operation, and a related device is portable and can be used to detect the polycyclic aromatic hydrocarbons in edible oil onsite.

Owner:HEFEI UNIV OF TECH

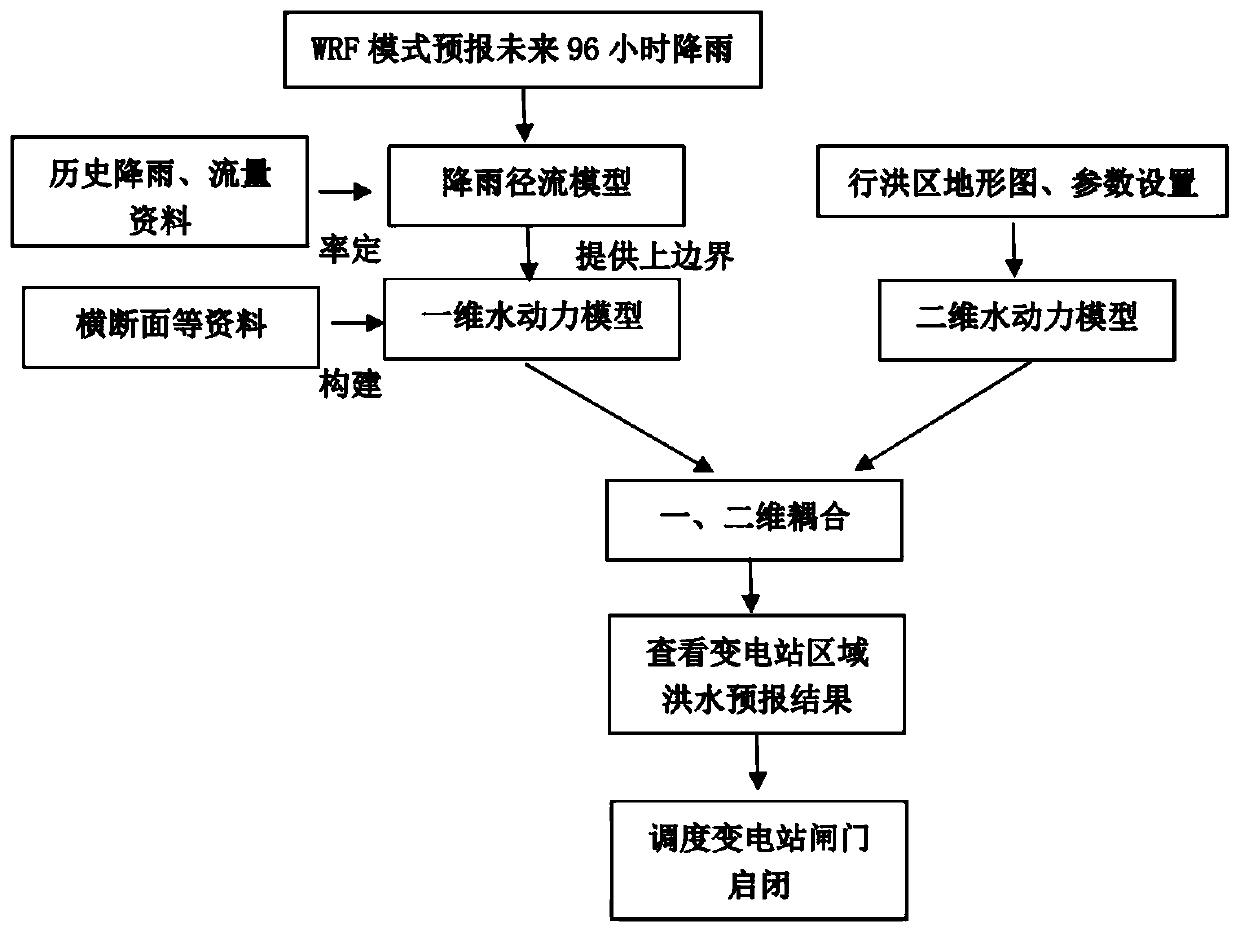

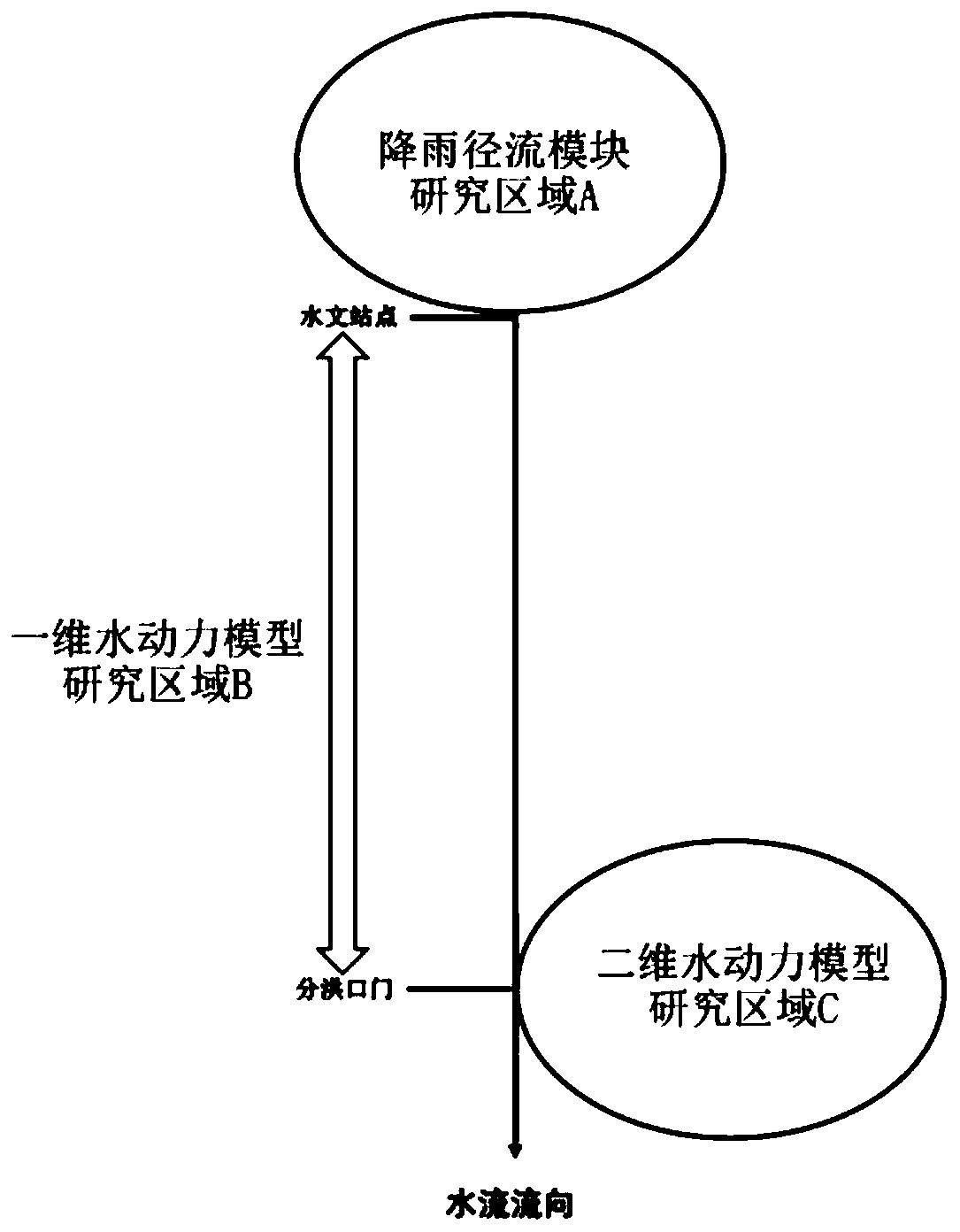

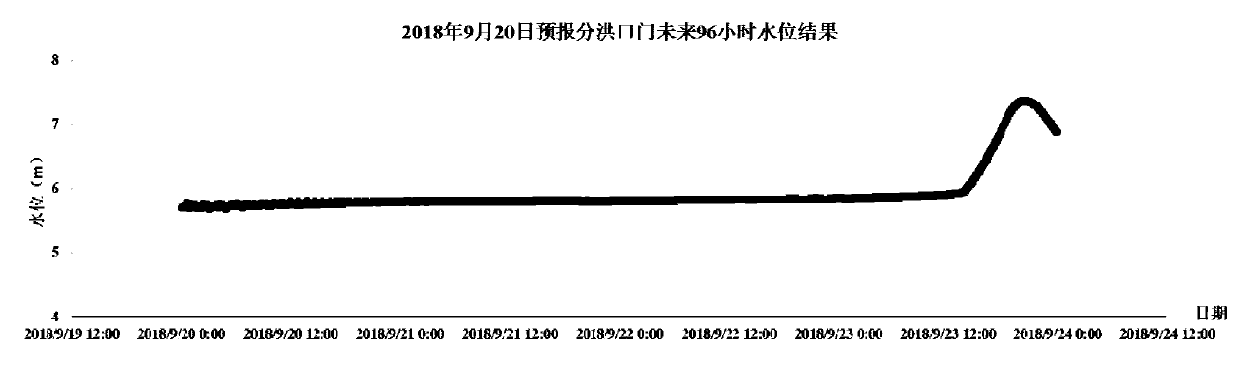

Method for dispatching flood gate of transformer substation

InactiveCN110565594AClose enoughAvoid lostBarrages/weirsHydraulic modelsRainfall runoffSufficient time

The invention discloses a method for dispatching a flood gate of a transformer substation, and belongs to the field of electric power engineering and flood control project. The method includes the following steps that a coupling model of a rainfall runoff model, a one-dimensional hydrodynamic model and a two-dimensional hydrodynamic model of an area where the transformer substation is located is established; rainfall forecast data within the preset time are obtained, a time series file is made and input into the rainfall runoff model, the rainfall runoff model serves as the boundary conditionof the one-dimensional hydrodynamic model, and the coupling model operates to obtain a forecast result of the one-dimensional hydrodynamic model for the water level of a flood diversion gate and a forecast result of the two-dimensional hydrodynamic model for the highest flood discharge water level in the transformer substation area; and the forecast results are analyzed, and it is judged that whether the flood gate of the transformer substation needs to be closed or not. According to the method, the possibility of flood occurring in the area where the transformer substation is located is estimated in advance, thus it is ensured that the flood gate of the transformer substation has sufficient time to be closed, and the loss caused by untimely closure of the flood gate is avoided.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

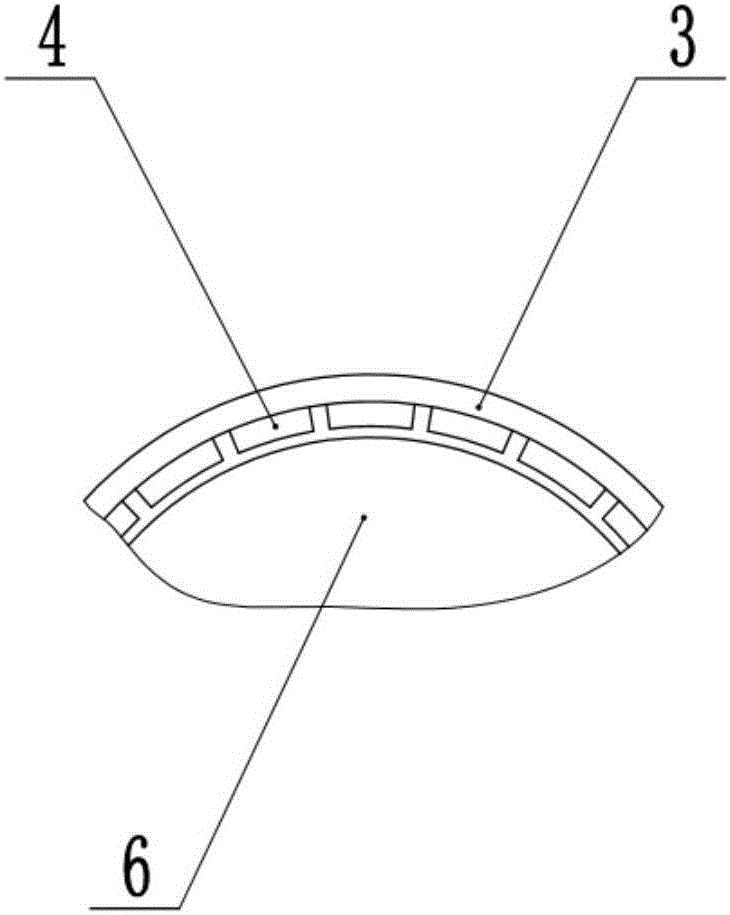

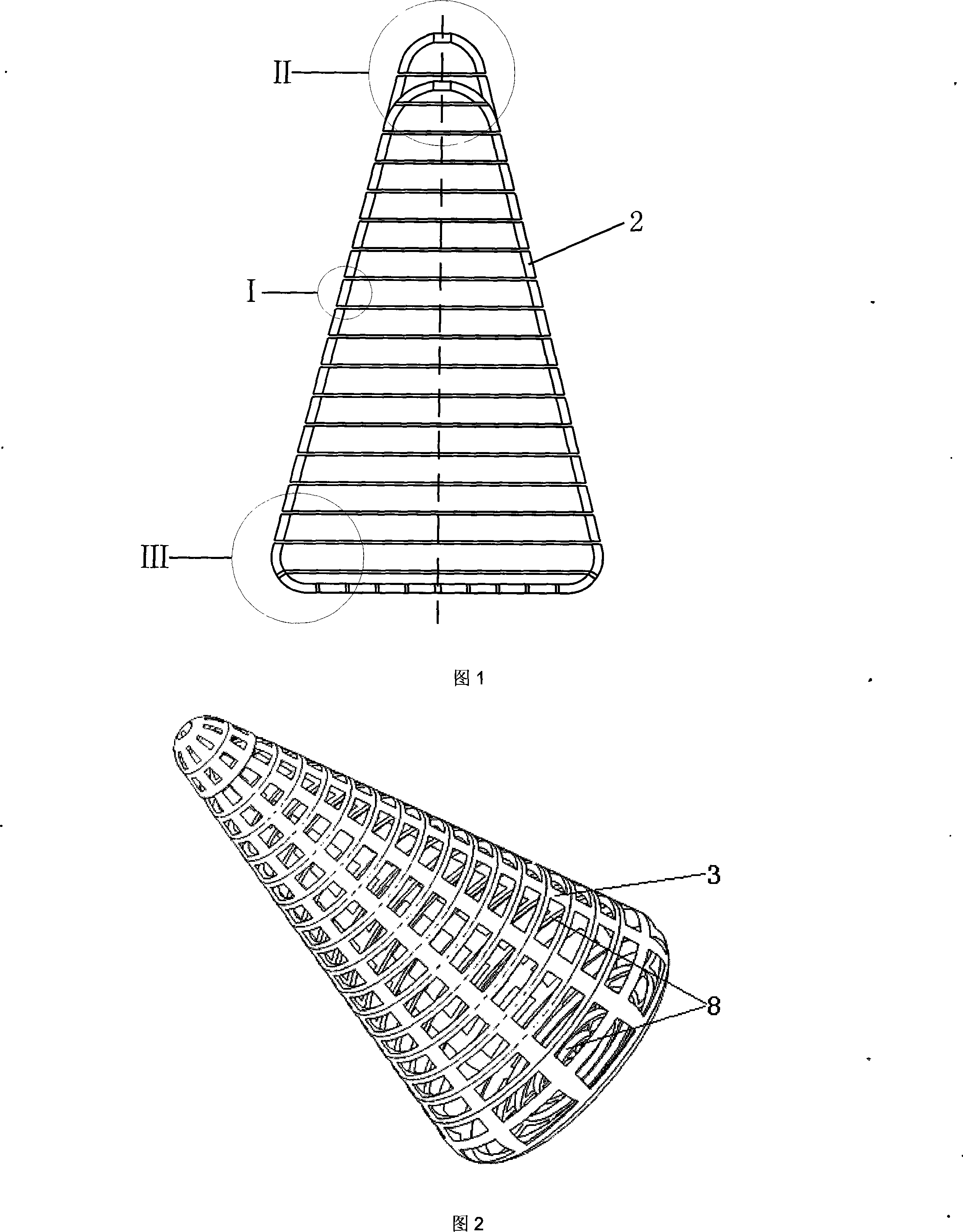

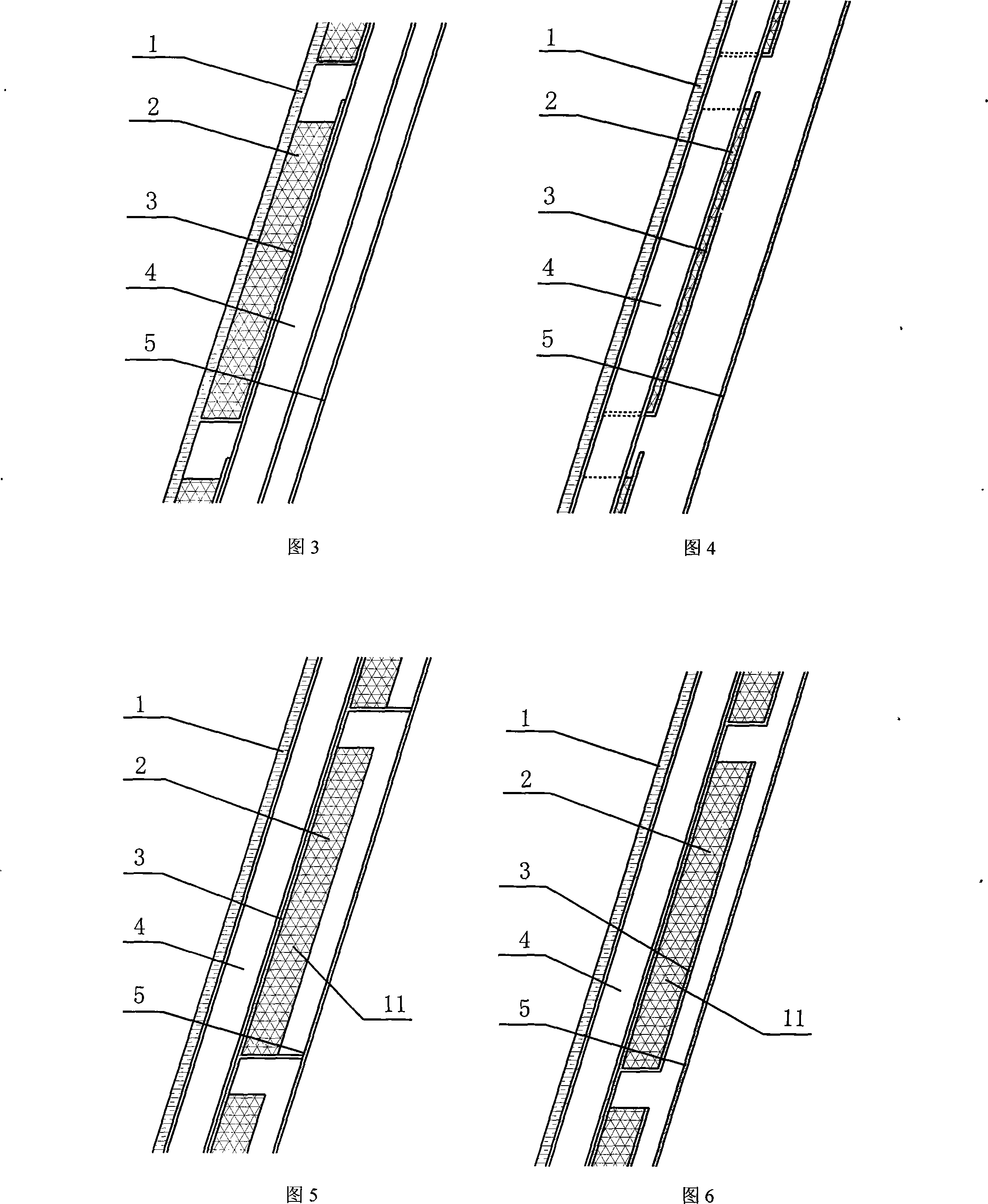

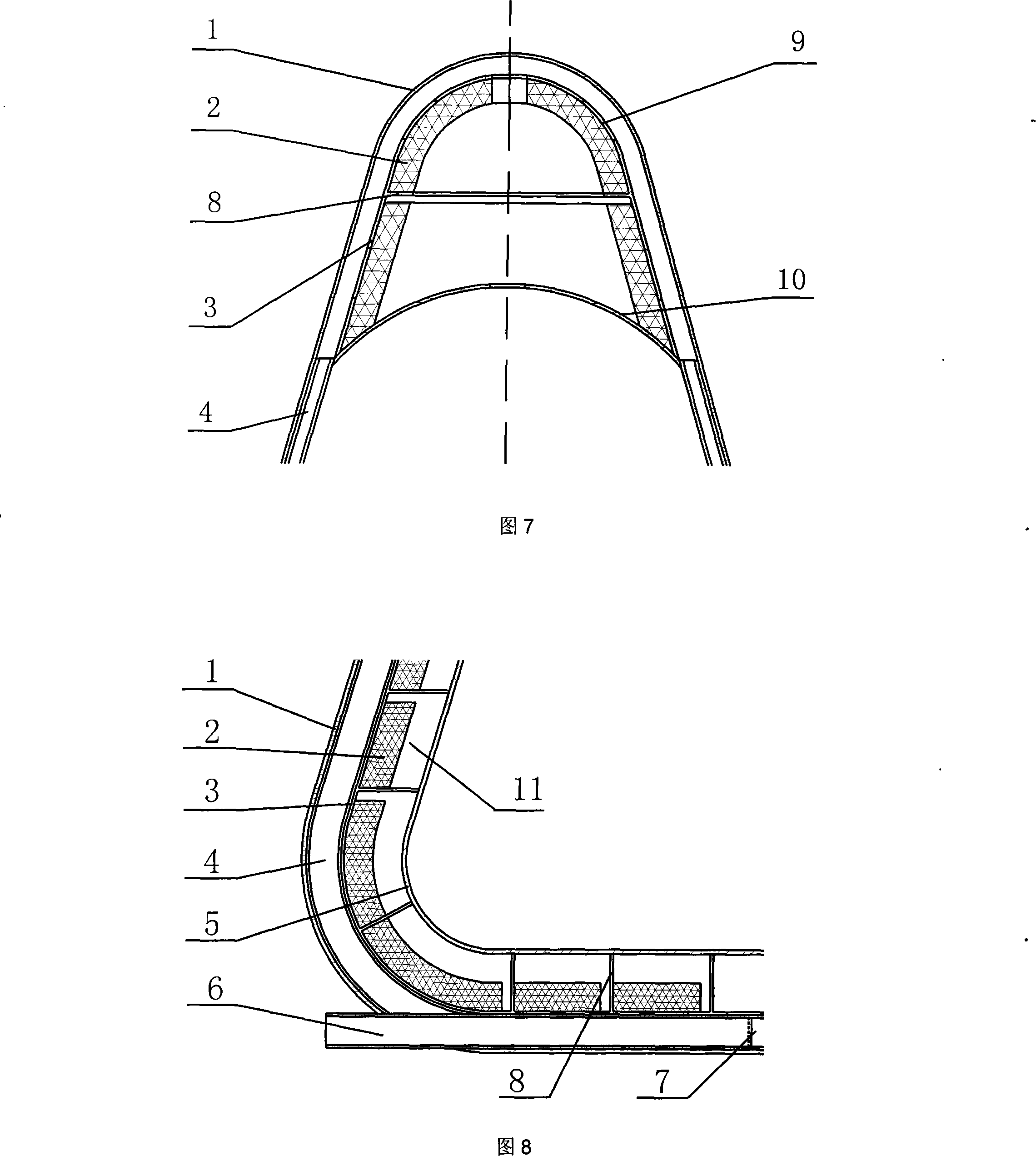

Space cold shielding harness layered liquid-storing refrigerating device

InactiveCN101234676AClose enoughLow flow resistanceCosmonautic thermal protectionMachines using refrigerant evaporationHeat transmissionEngineering

The invention relates to a refrigeration device with liquid stored in different layers in a space cold shielding system, which comprises capillary materials, a capillary material bracket, an inlet pipe of secondary diffusion, a discharging pipe of secondary diffusion and a diffuser, wherein, the capillary material bracket is arranged between an outer layer of cold shielding and an inner layer of cold shielding and provided with the capillary materials divided by circular shapes; the capillary material bracket at an upper part of each circular layer is provided with a vent port. The inlet pipe of secondary diffusion is arranged between the capillary material bracket and the inner layer of cold shielding; an outlet of the inlet pipe of secondary diffusion is connected with the diffuser, an outlet of which is connected with the discharging pipe of secondary diffusion; a clearance is kept between the inlet pipe of secondary diffusion and the inner layer of code shielding. The refrigeration device solves the difficult problems of valid storage of refrigerant during the space dynamic refrigeration of variable pressure, temperature and flow, improves the efficiency of space heat transmission, increases the efficiency of space refrigeration with phase change, realizes the relative stability of space refrigeration, and realizes the effective control of temperature on the surface of the space cold shielding system.

Owner:张周卫

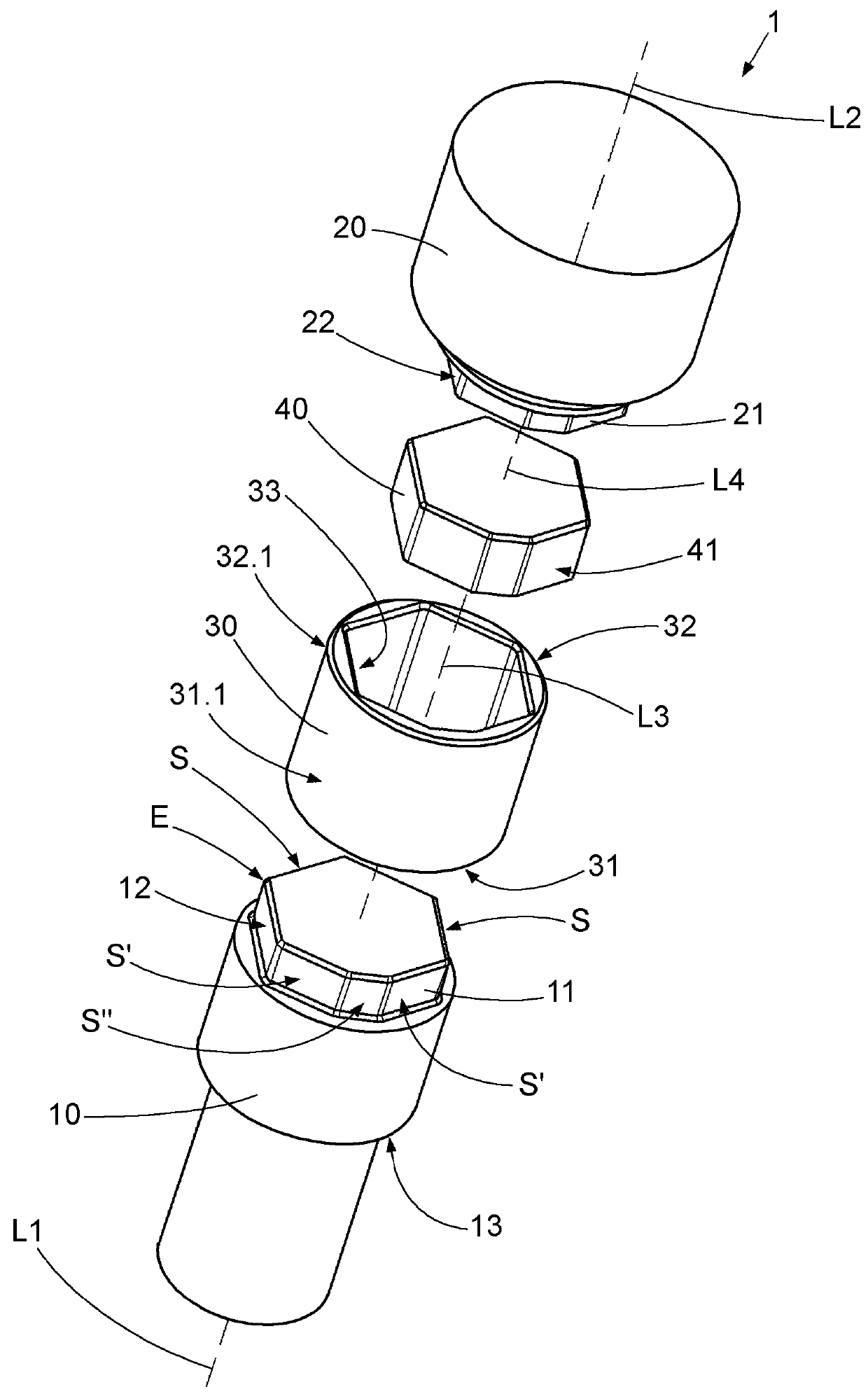

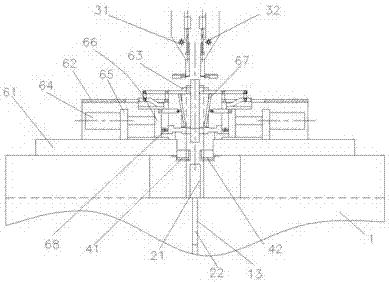

Fuel injector

ActiveCN103306876AExplicit rotation positioningClear positioningMachines/enginesSpecial fuel injection apparatusEngineeringInjector

The invention relates to a fuel injector (1) comprising an injection nozzle (10), a switching valve (20) and a connecting sleeve (30) that is arranged between the injection nozzle (10) and the switching valve (20), wherein the injection nozzle has a predetermined outer nozzle contour (12) on a longitudinal end section (11) thereof and the switching valve has a predetermined outer valve contour (22) on a longitudinal end section (21) thereof, and wherein the connecting sleeve has a predetermined inner sleeve contour (33) into which, from a first longitudinal end (31) of the connecting sleeve, the injection nozzle fits with the outer nozzle contour thereof in a form-fitting manner such that the injection nozzle is fixed in a defined alignment relative to the connecting sleeve, and into which, from a second longitudinal end (32) of the connecting sleeve, the switching valve fits with the outer valve contour thereof in a form-fitting manner such that the switching valve is fixed in a defined alignment to the connecting sleeve.

Owner:MAN ENERGY SOLUTIONS SA

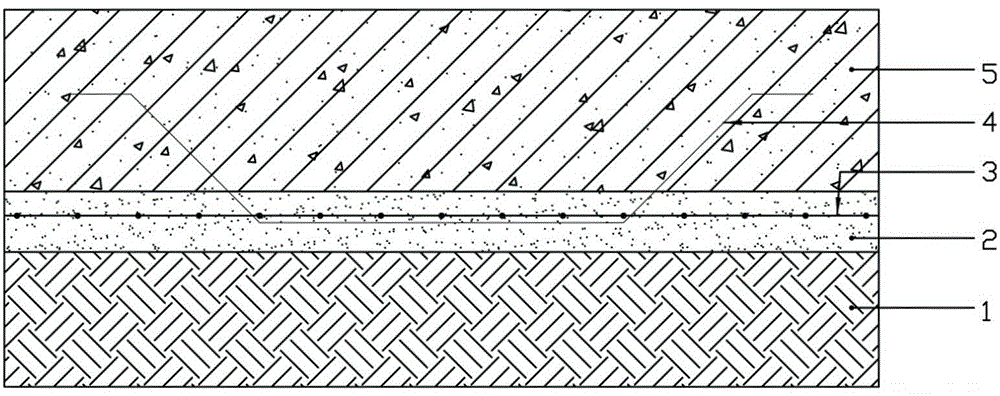

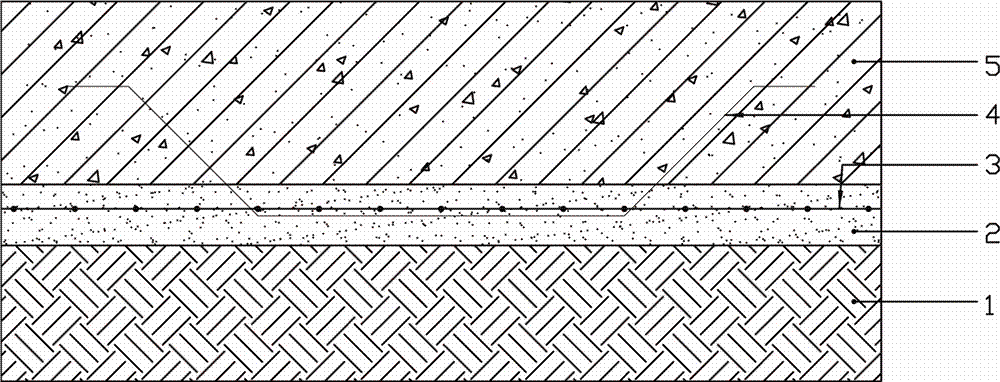

Construction method of cave-imitating decorative surface

ActiveCN105155847AShorten the timeLow decorativeCovering/liningsBuilding material handlingRebarFiber-reinforced concrete

A construction method of a cave-imitating decorative surface comprises the steps of 1), molding a structure interior cave clay model; 2), manufacturing the decorative surface, wherein the clay model is coated with a layer of mortar, steel wire gauzes and tied bars are laid in the mortar, the two ends of the tied bars extend into the steel wire gauzes to fasten the steel wire gauzes and the clay model is coated with another layer of mortar after the mortar is initially solidified, or the steel wire gauzes with the tied bars embedded are added into the mortar until the mortar is solidified; 3), binding steel bars and manufacturing side models on the outer side of the mortar according to the design configuration, and then pouring reinforced concrete or steel fiber reinforced concrete to form a concrete structure layer; 4),hollowing the interior clay model after the concrete structure layer is solidified and stabilized and cleaning the inner wall to obtain the cave-imitating decorative surface. According to the invention, the decorative surface and the structure layer are formed at a time, so that the labor hour is saved; the clay model can be manufactured by using local materials and can be recycled, so that environmental friendliness is high and materials are saved.

Owner:SHANGHAI GARDEN ENG CO LTD

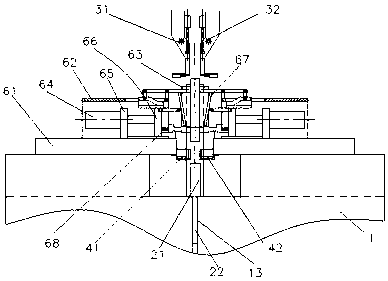

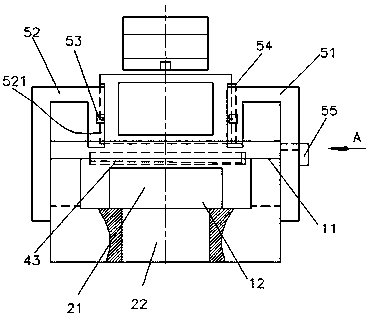

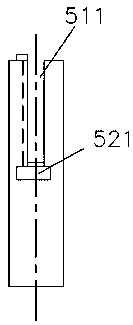

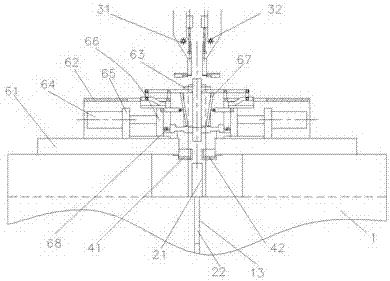

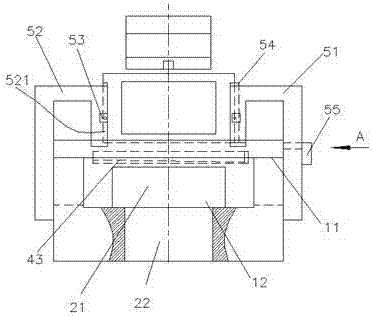

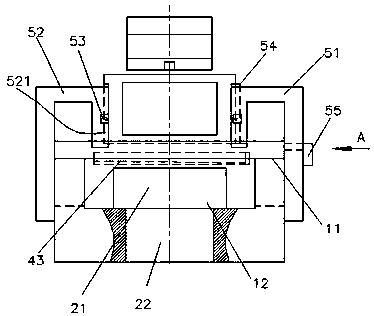

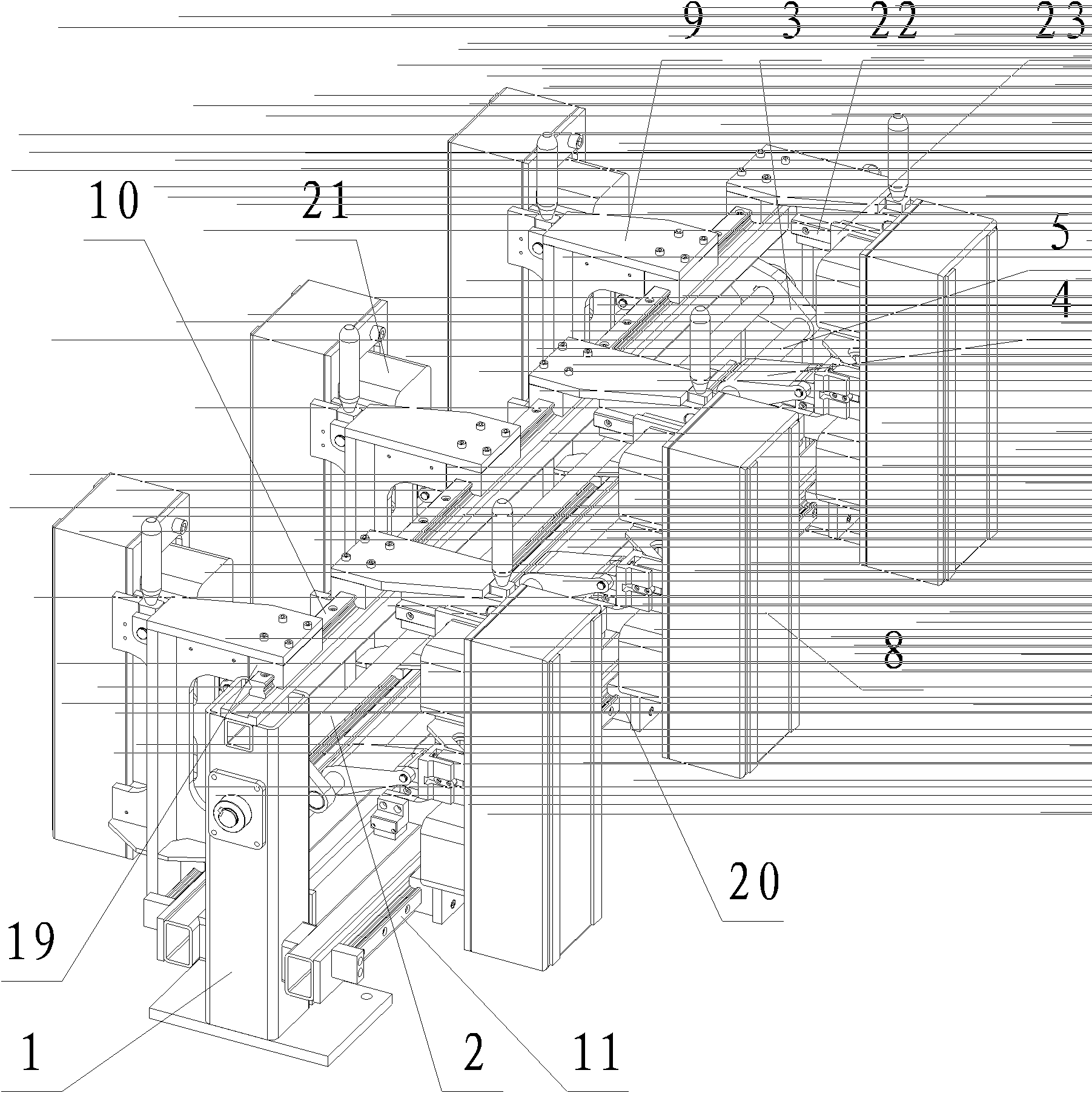

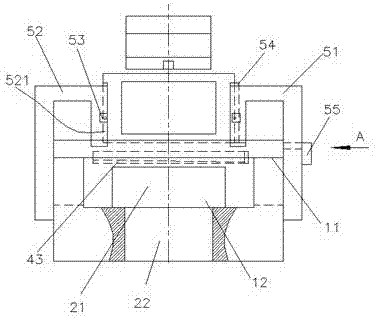

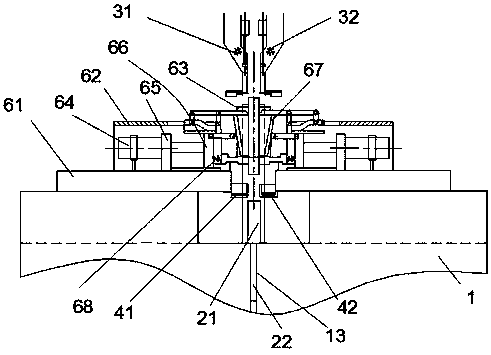

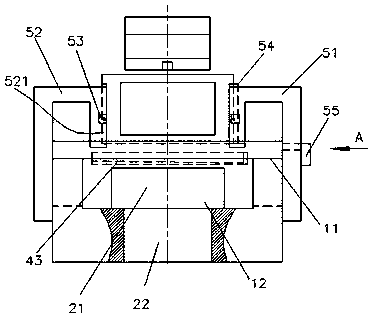

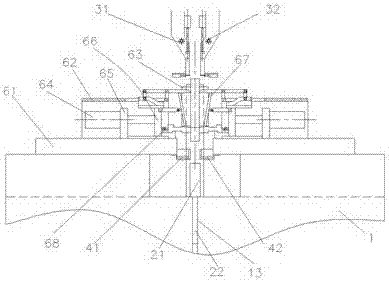

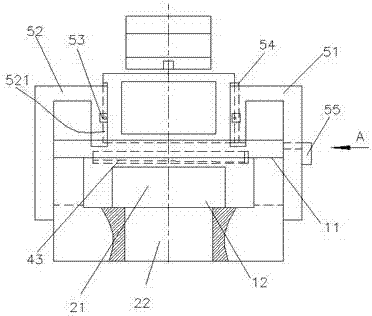

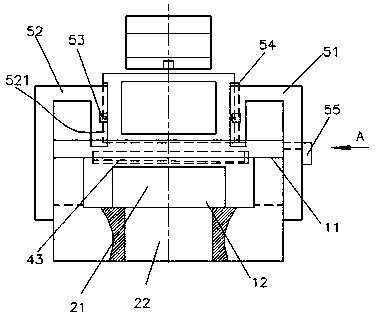

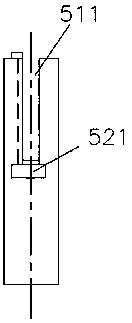

Novel bipolar battery panel pressing formation device

InactiveCN108232329ASame structureImprove productivityFinal product manufactureLead-acid accumulators constructionEngineeringElectrical and Electronics engineering

The invention discloses a novel bipolar battery panel pressing formation device. The novel bipolar battery panel pressing formation device comprises a base plate clamping device, two groups of formingdevices, a blanking device, a remaining material collecting device, a second blanking device and a machine frame; the machine frame is provided with a U groove with an upward opening; the second blanking device is arranged in the U groove; a guide rail in a left-right direction is arranged on each of the front side and the back side of the upper surface of the machine frame; the two groups of forming devices have the same structure and comprise a left forming device and a right forming device; and the left forming device and the right forming device are arranged on the left side and the rightside of the upper surface of the machine frame and can slide left and right along the guide rails. The novel bipolar battery panel pressing formation device is simple in structure, convenient to control and convenient and rapid in operation, can automatically realize blanking work, improves working efficiency, guarantees the forming quality and reduces the labor intensity of workers.

Owner:楼天涯

Letter box device

InactiveCN107280430AConsistent firmnessSame structureEnvelopes/bags making machineryKitchen equipmentUltimate tensile strengthComputer engineering

Owner:张清付

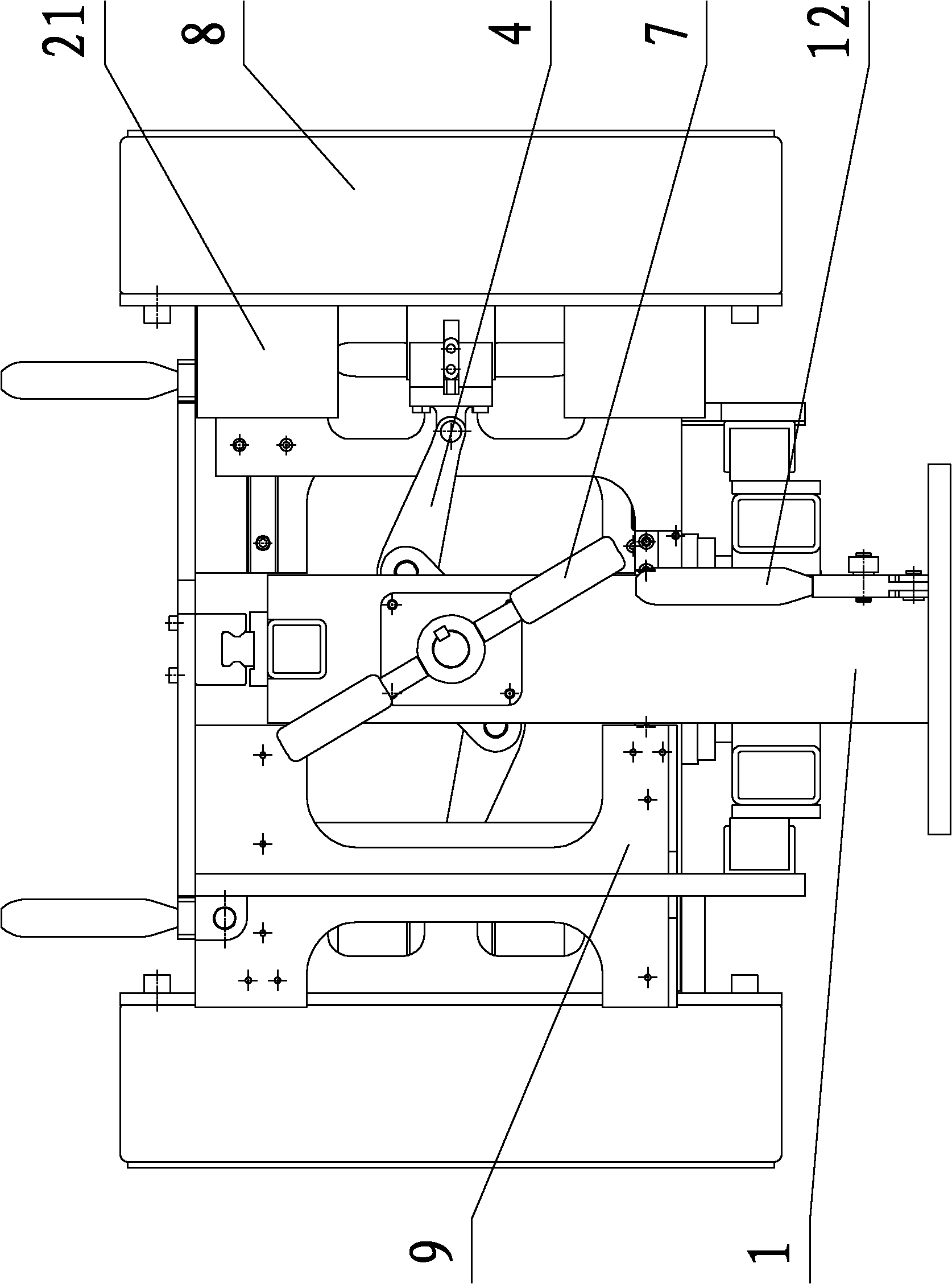

Novel new energy automobile device

InactiveCN108232328ASame structureImprove productivityFinal product manufactureLead-acid accumulators constructionNew energyEngineering

The invention discloses a novel new energy automobile device. The novel new energy automobile device comprises a clamping and fixing device, two groups of extruding devices, an unloading device, a storage device, a second unloading device and a base frame; the base frame is provided with a U-shaped groove with an upward mouth part; the second unloading device is arranged in the U-shaped groove; arail in a left-right direction is arranged on each of the front side and the back side of the upper surface of the base frame; the two groups of extruding devices have the same structure and comprisea left extruding device and a right extruding device; and the left extruding device and the right extruding device are arranged on the rails on the left side and the right side of the upper surface ofthe base frame correspondingly and can slide along the rails left and right. The novel new energy automobile device is simple in structure, convenient to control and convenient and rapid in operation, and can automatically realize feeding work, improve working efficiency, guarantee forming quality and reduce the labor intensity of workers.

Owner:吴美俊

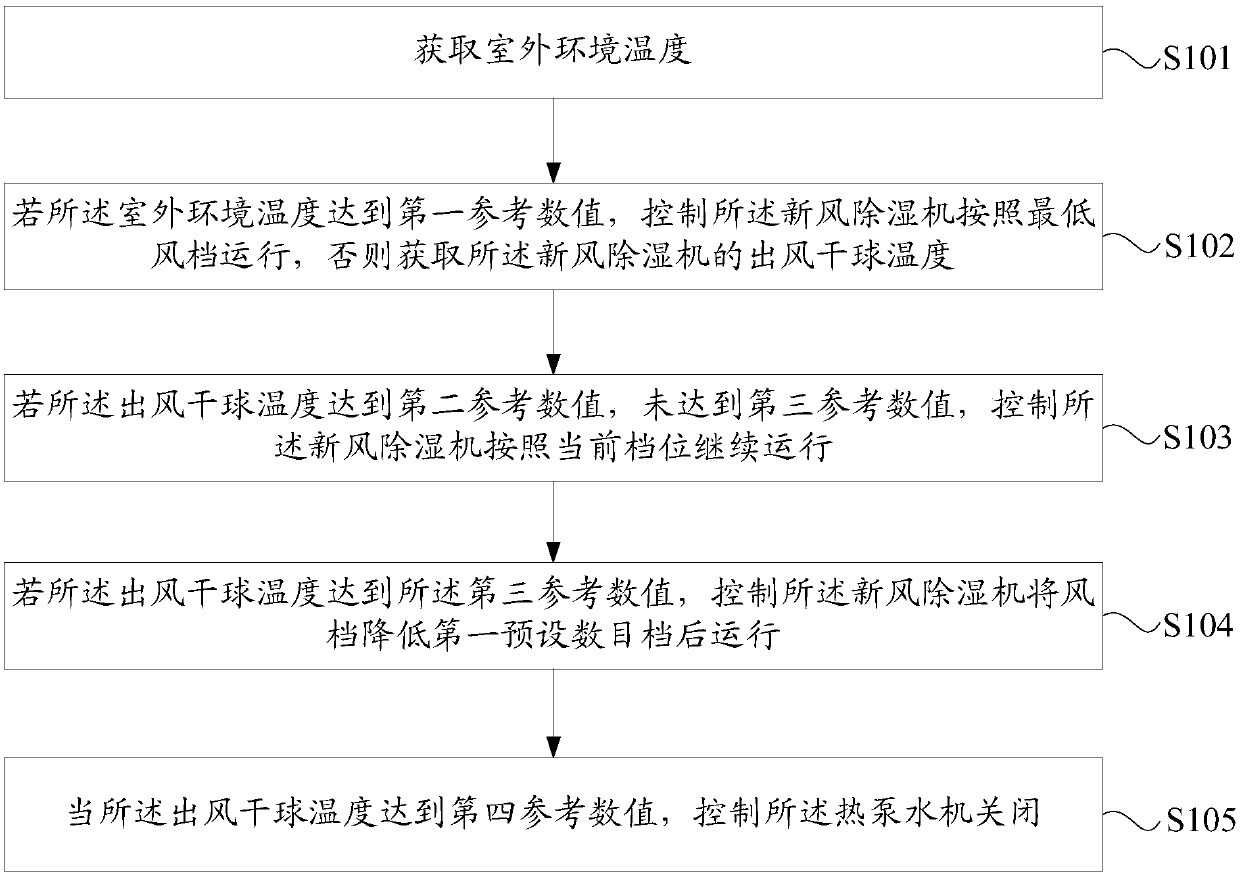

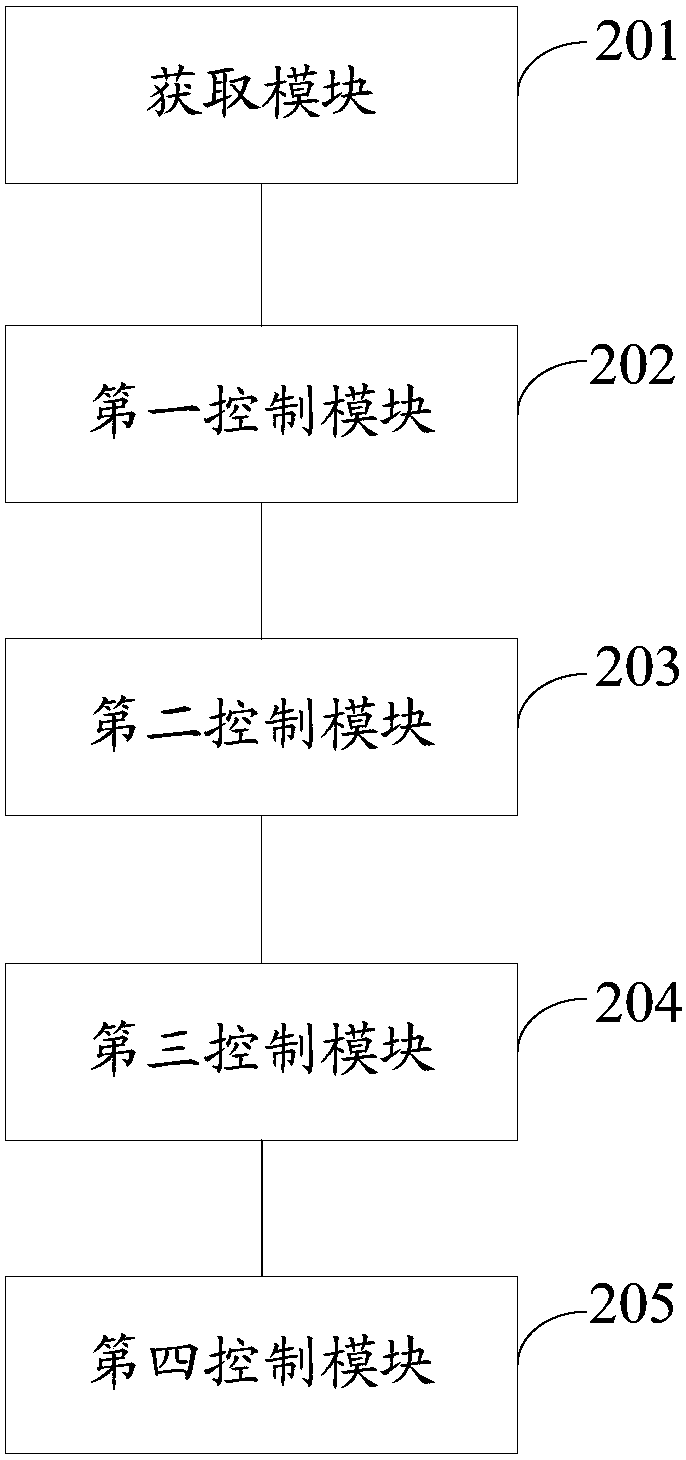

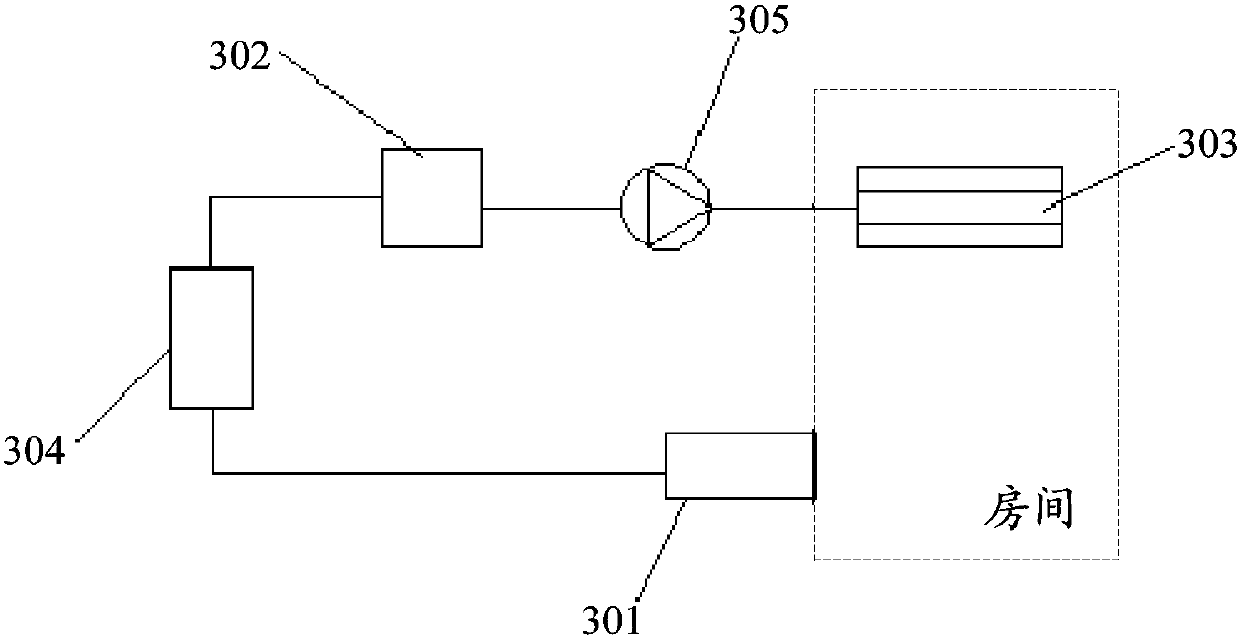

Control method and related device for radiant fresh air air conditioning system

ActiveCN105674501BRaise the dew point temperatureLower dew point temperatureFluid heatersMechanical apparatusFresh airEngineering

The invention discloses a control method of a radiation fresh air conditioning system and a related device. The method comprises the steps of: obtaining an outdoor environment temperature; controlling a fresh air dehumidifier to operate according to a lowest air gear if the outdoor environment temperature reaches a first reference numerical value, otherwise, obtaining an air outlet dry ball temperature of the fresh air dehumidifier; controlling the fresh air dehumidifier to continuously operate according to the present gear if the air outlet dry ball temperature reaches a second reference numerical value and dose not reach a third reference numerical value; controlling the fresh air dehumidifier to operate after reducing the air gear to a first preset number gear if the air outlet dry ball temperature reaches the third reference numerical value; and controlling a heat pump water machine to be closed if the air outlet dry ball temperature reaches a fourth reference numerical value. The control method can effectively reduce the closing frequency of the heat pump water machine and a water value on the basis of effectively preventing generation of condensation on the radiation terminal surface, so that the refrigerating capacity can be supplied more sufficiently, and the comfort of people in rooms is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Automatic public opinion monitoring method based on internet hierarchical structure storage

ActiveCN102214227BSuitable for reading habitsAccurately express needsTransmissionSpecial data processing applicationsPersonalizationThe Internet

The invention provides an automatic public opinion monitoring method based on internet hierarchical structure storage. The method comprises the following steps that: a user uploads a monitoring request; and a server analyzes the monitoring request, acquires acceptable monitoring conditions of the server, realizes monitoring the internet by using a hierarchical structure storage monitoring method,filters and integrates public assessment information relevant to a subject request of the user by using a regular expression technology to generate a personalized monitoring result, and sends the personalized monitoring result to the user by various modes. By the method, a machine can intelligently perform semantic analysis on a monitoring subject which is submitted by the user, the monitoring ofa subject which most meets a monitoring requirement of the user on the internet and the relevant public assessment information is realized, the monitoring result is automatically generated by centering on the subject, and a user can request the style and form of the generated monitoring result and make a mode of acquiring the monitoring result. Therefore, the monitoring process is more personalized, more convenient, more abundant and more vivid.

Owner:SOUTH CHINA UNIV OF TECH

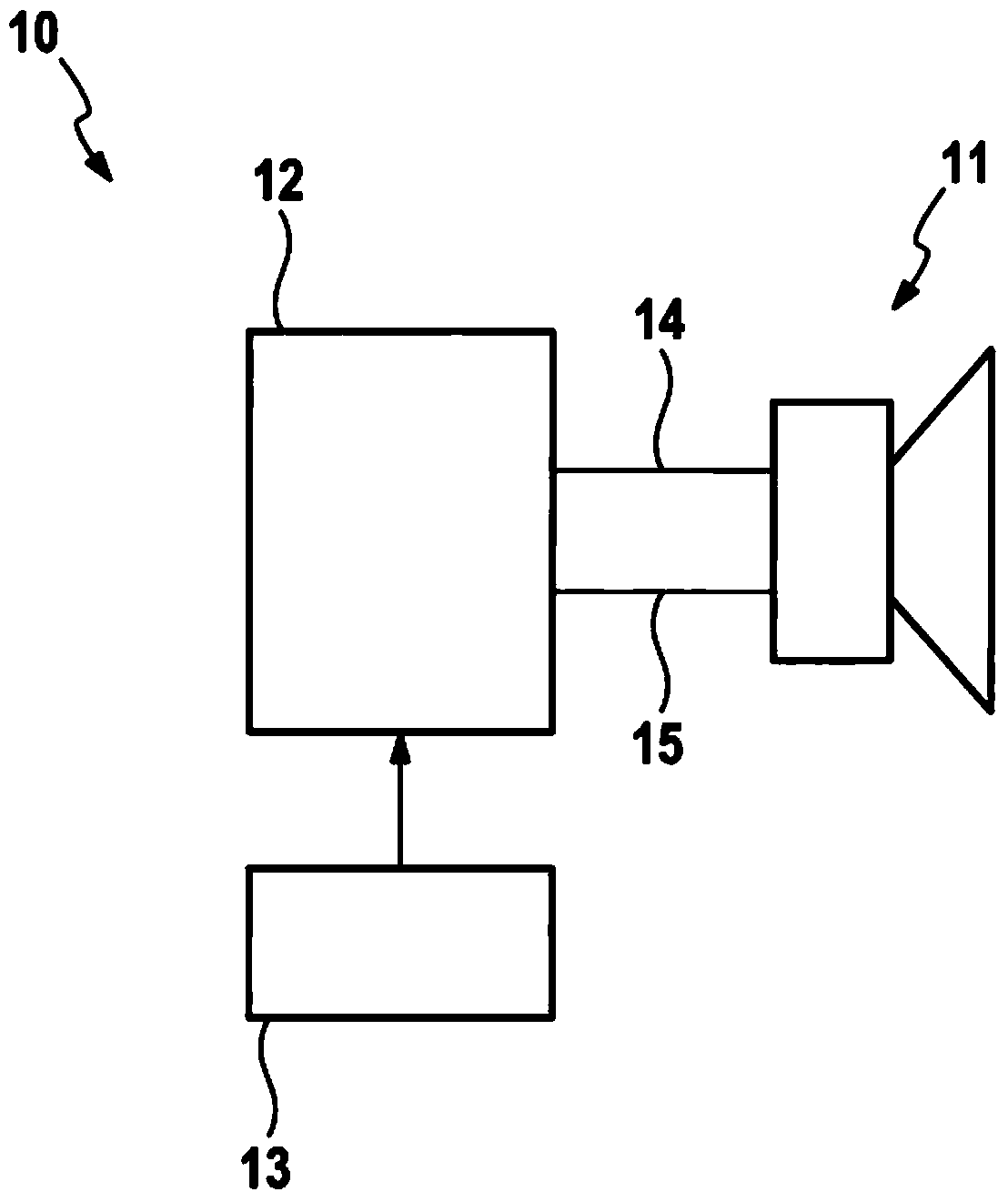

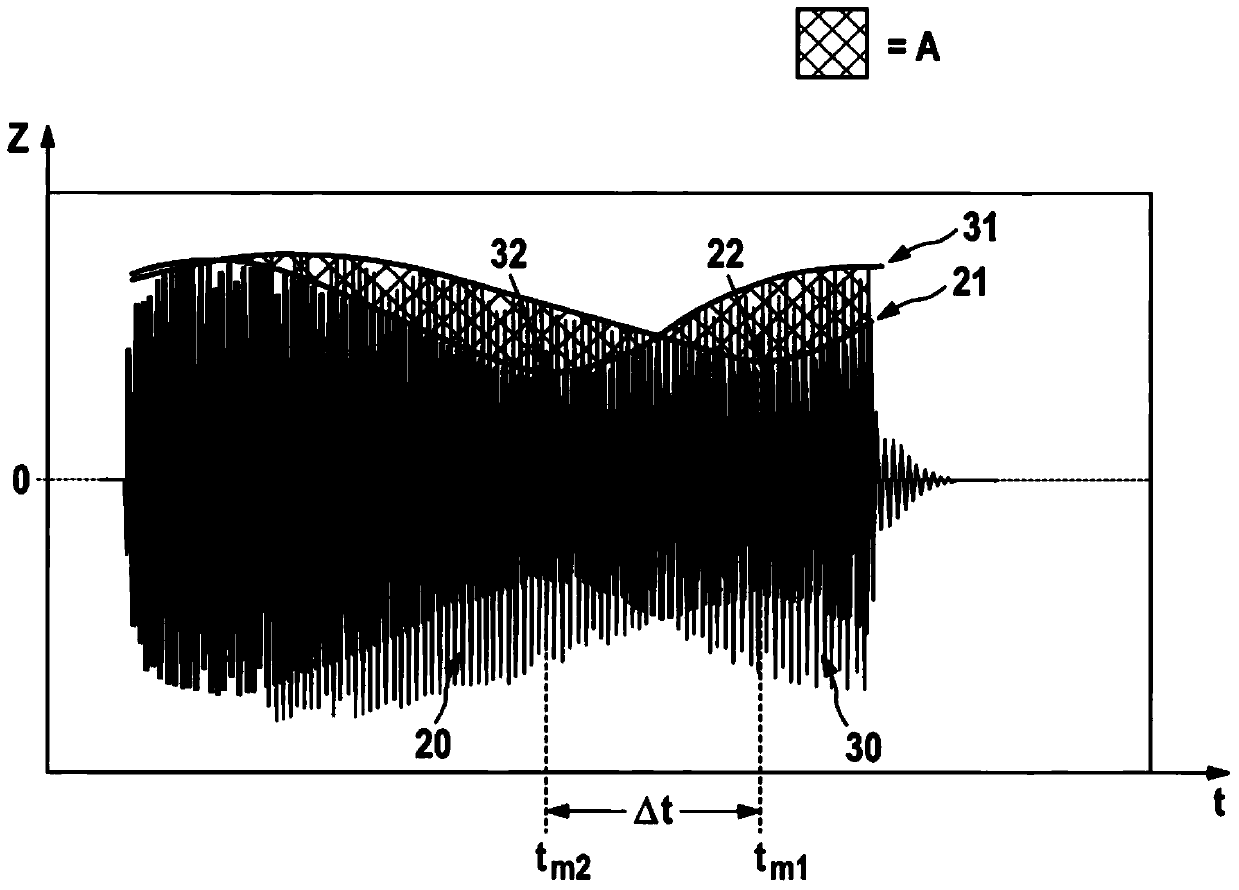

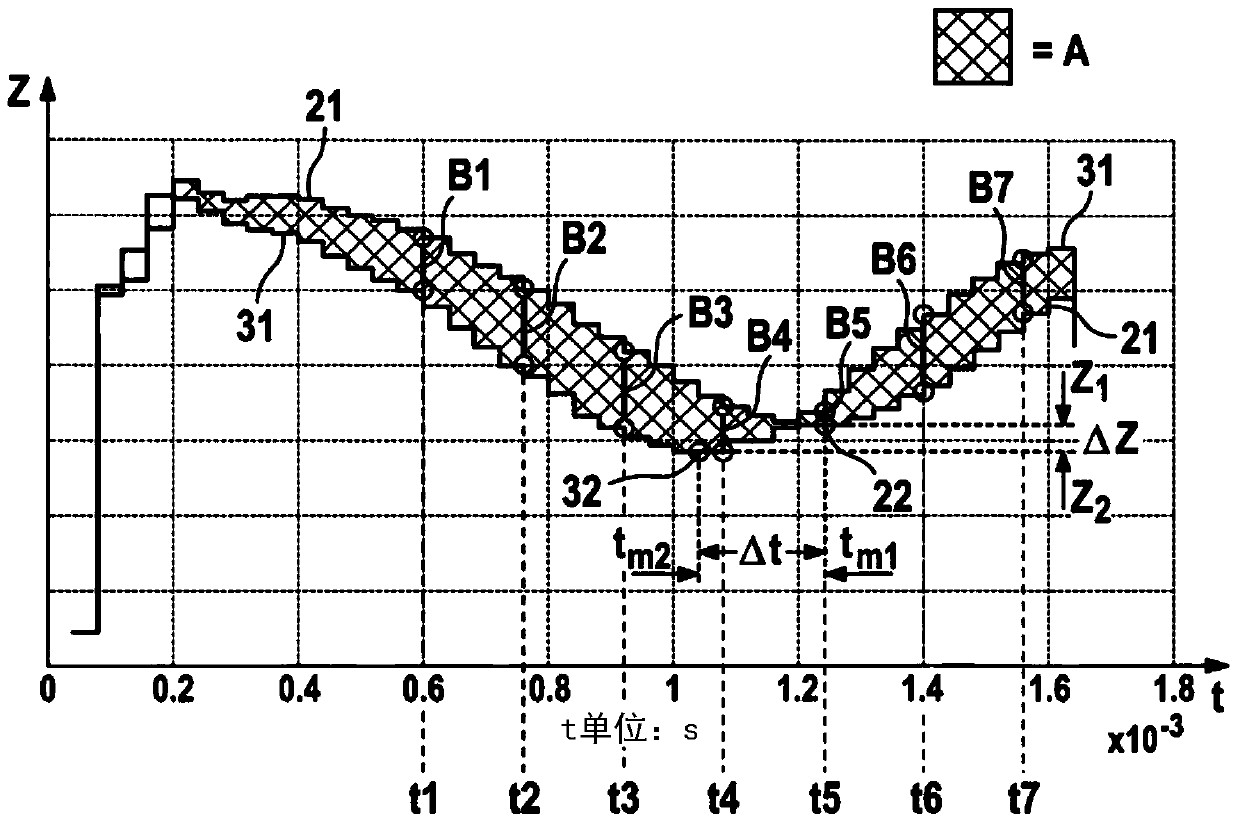

Method and apparatus for identifying faults in ultrasonic transducers by analyzing and processing impedance envelopes

ActiveCN104808195BClose enoughAccurate analysis and processingAcoustic wave reradiationUltrasonic sensorTransducer

The invention relates to a method and a device (10) for detecting malfunctions of an ultrasound transducer (11). The method comprises the following steps: loading the ultrasonic transducer with an excitation signal; obtaining an impedance signal (20), the impedance signal describing the impedance of the ultrasonic transducer with respect to the excitation signal; generating an impedance envelope (21) of the impedance signal; comparing Impedance envelope and reference envelope (31), wherein a fault is detected if the impedance envelope differs from the reference envelope. In this case, the excitation signal comprises a plurality of frequencies, in particular frequency sweeps, whereby the method can also be carried out during the transmitting operation of the ultrasound transducer. Therefore, a particularly reliable method for detecting faults of the ultrasonic transducer is proposed, which method can be carried out by means of the ultrasonic transducer during a distance measurement. The method is robust with respect to error detection for individual impedance values of the impedance signal.

Owner:ROBERT BOSCH GMBH

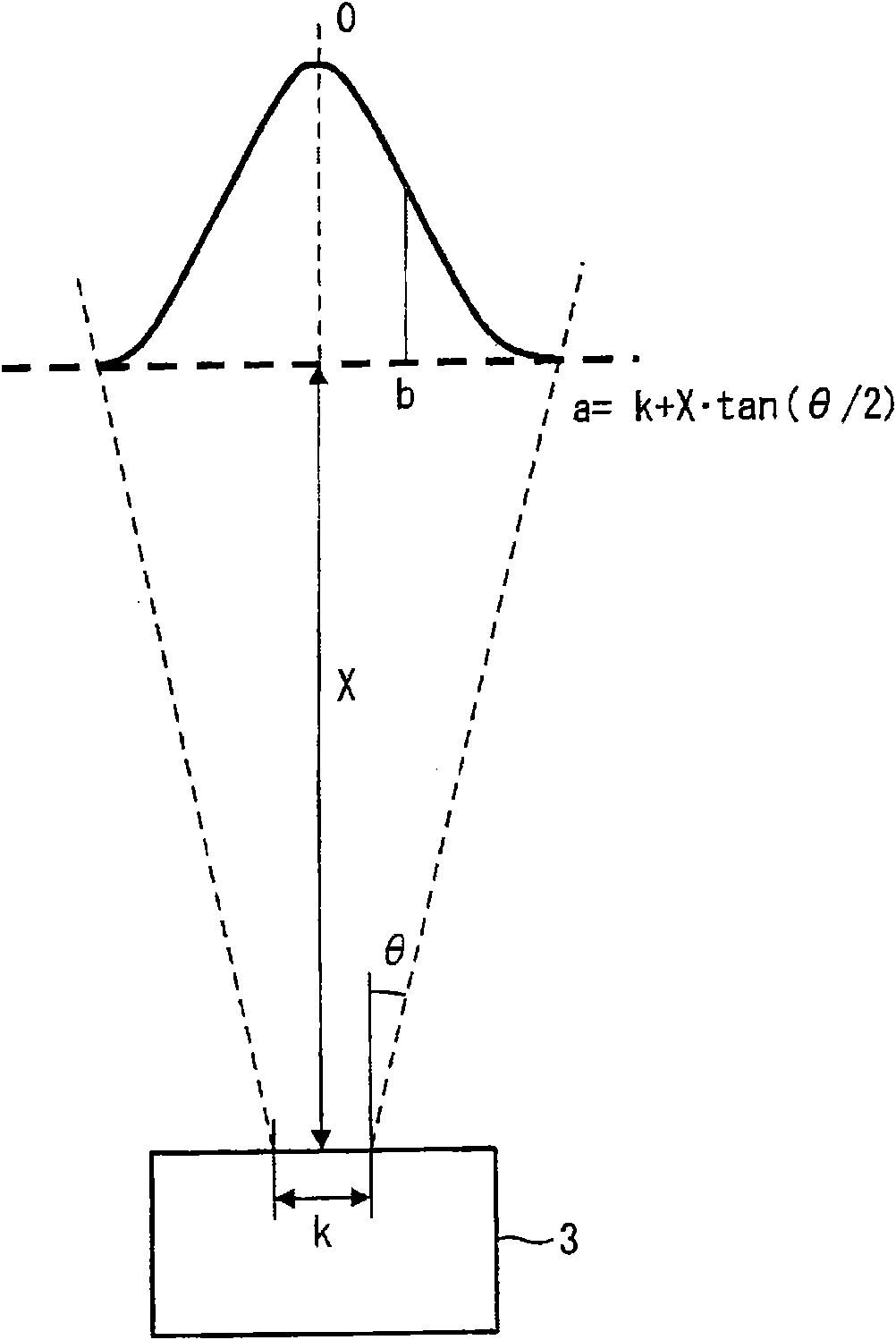

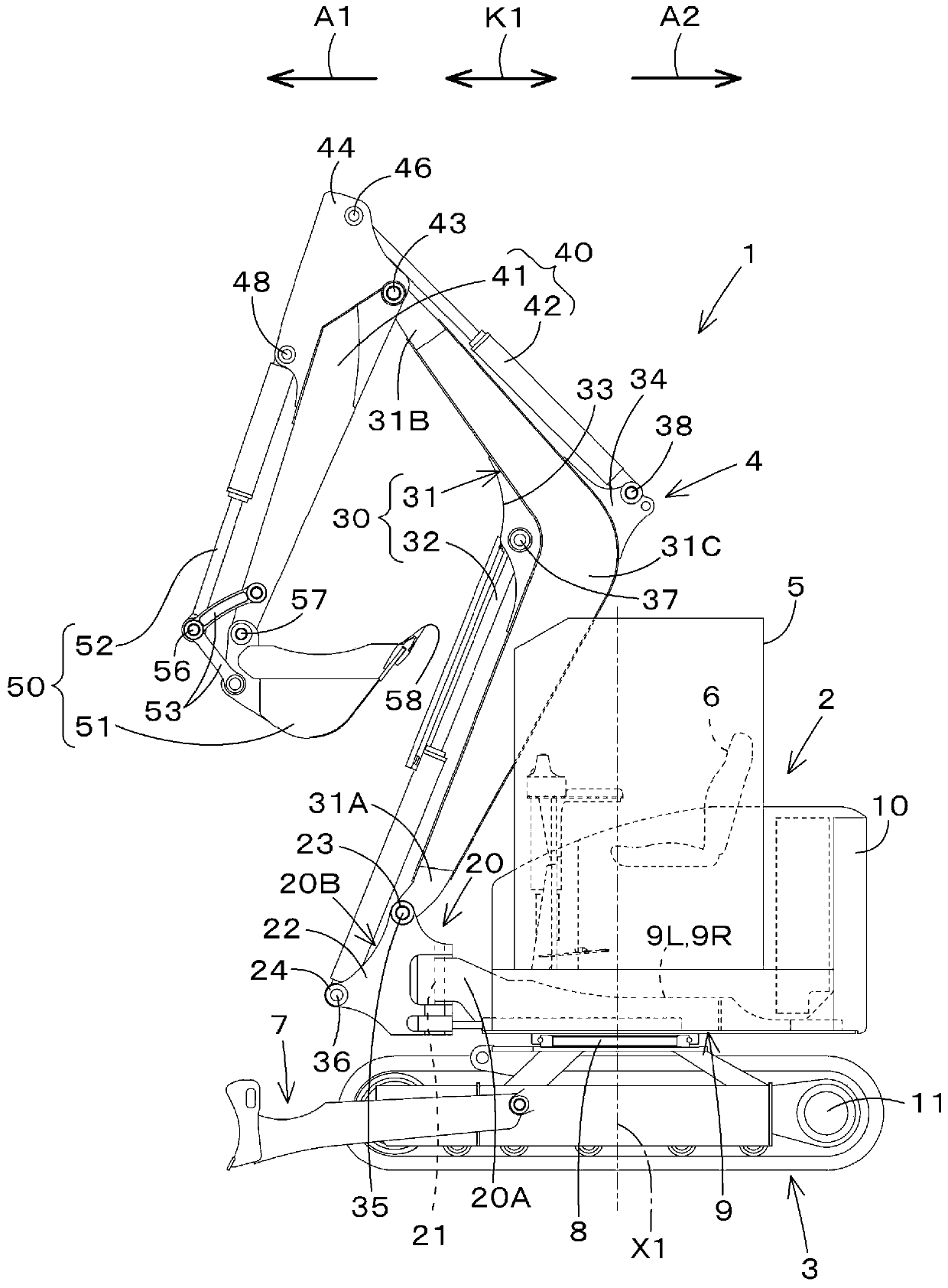

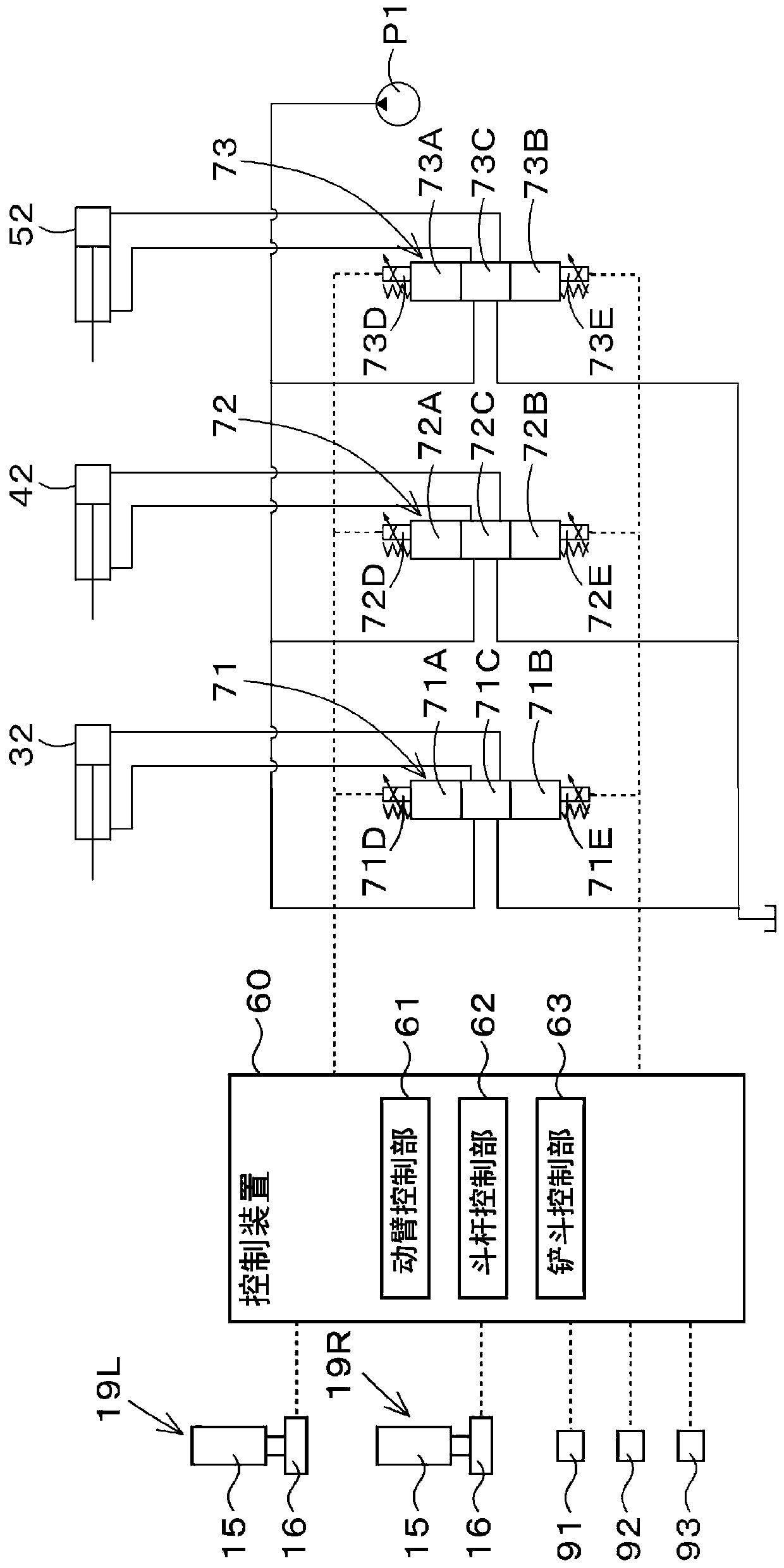

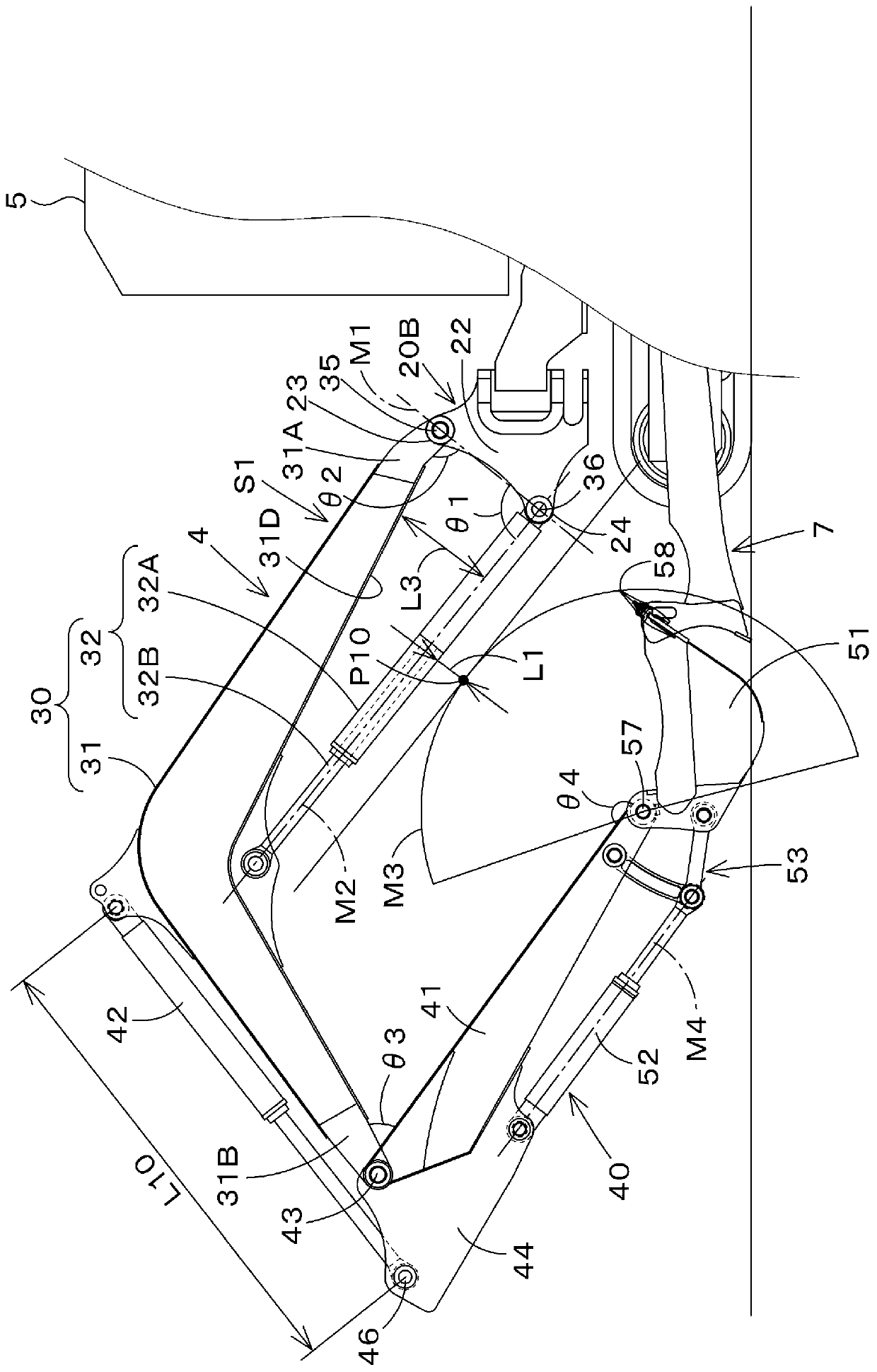

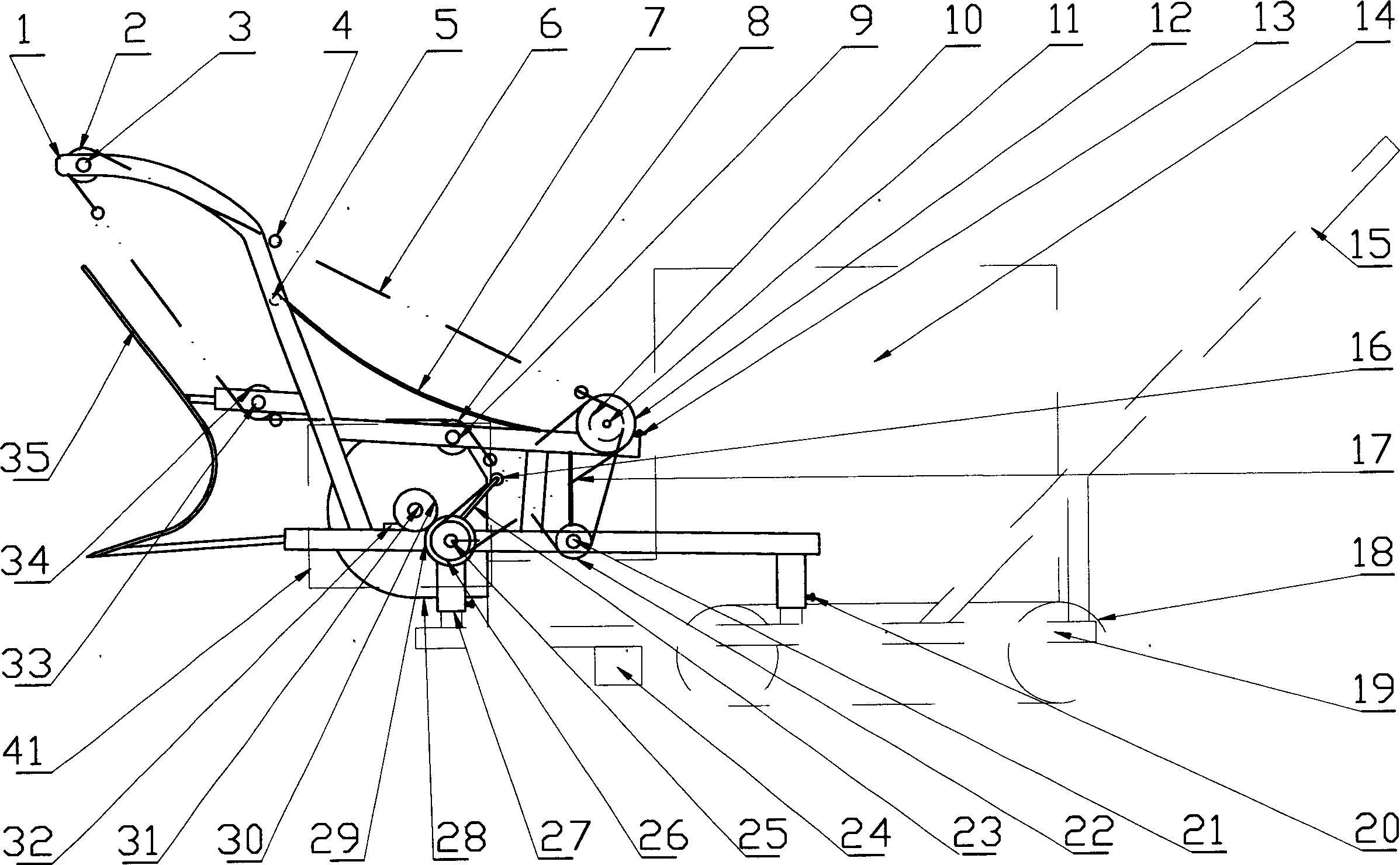

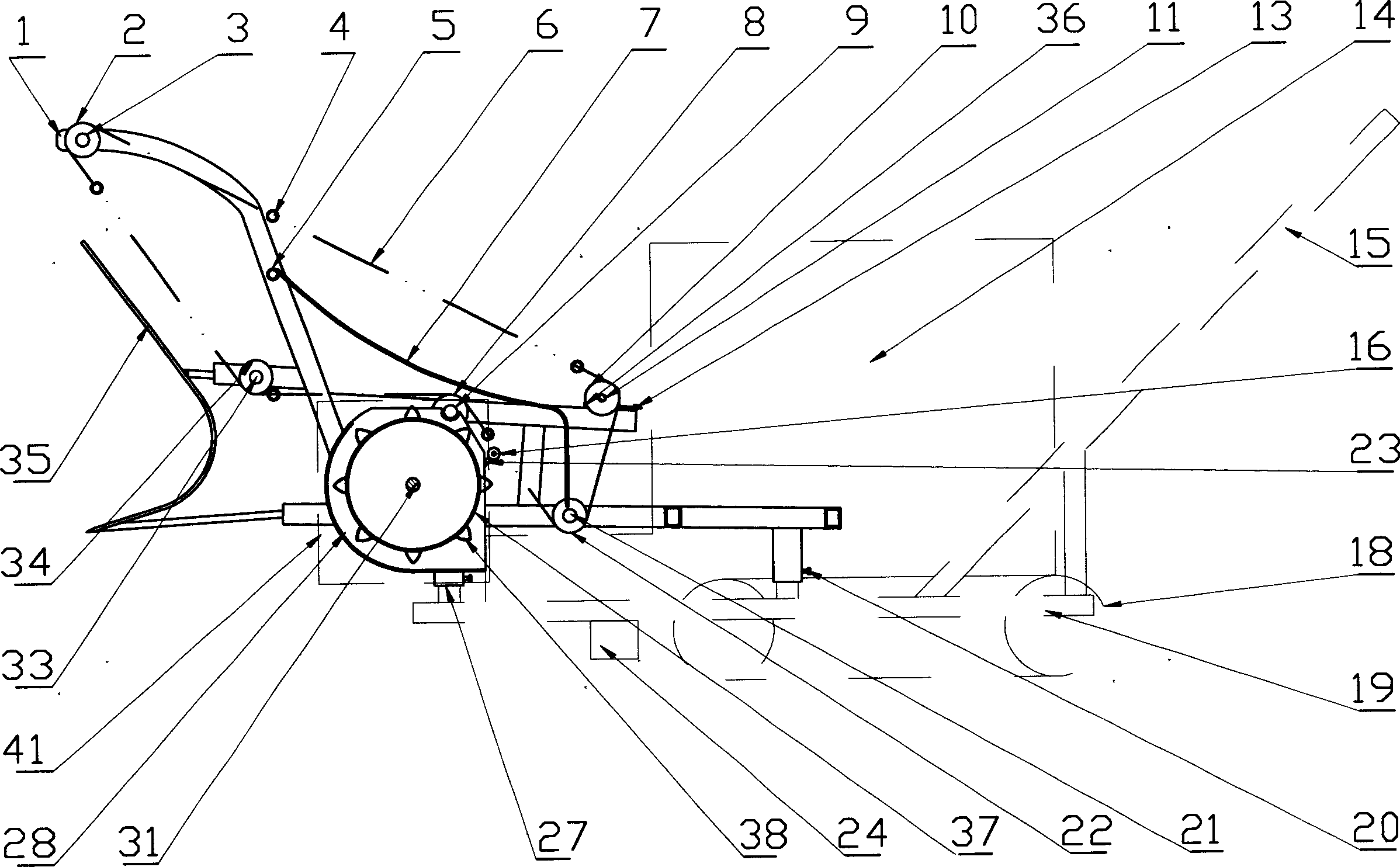

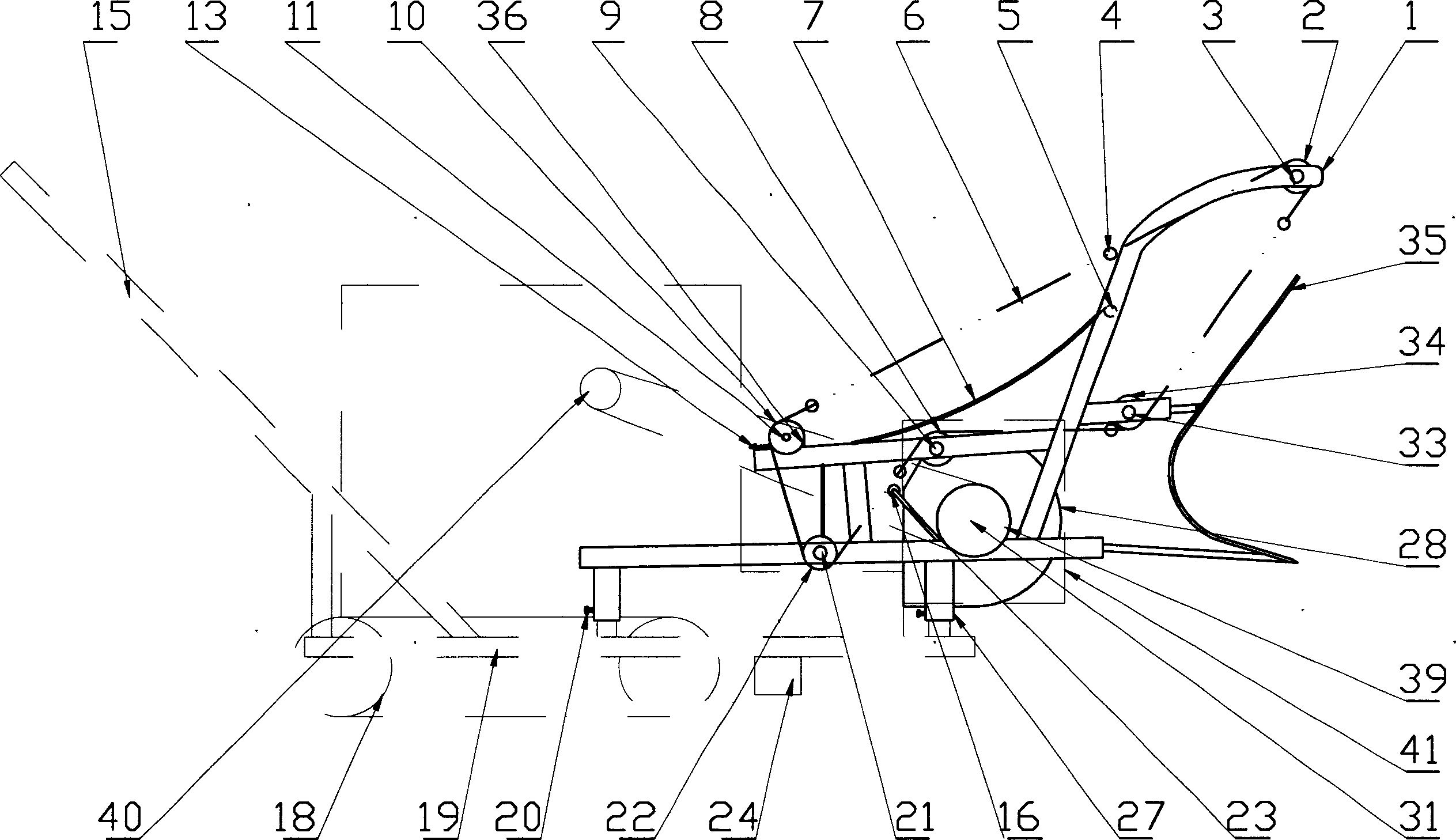

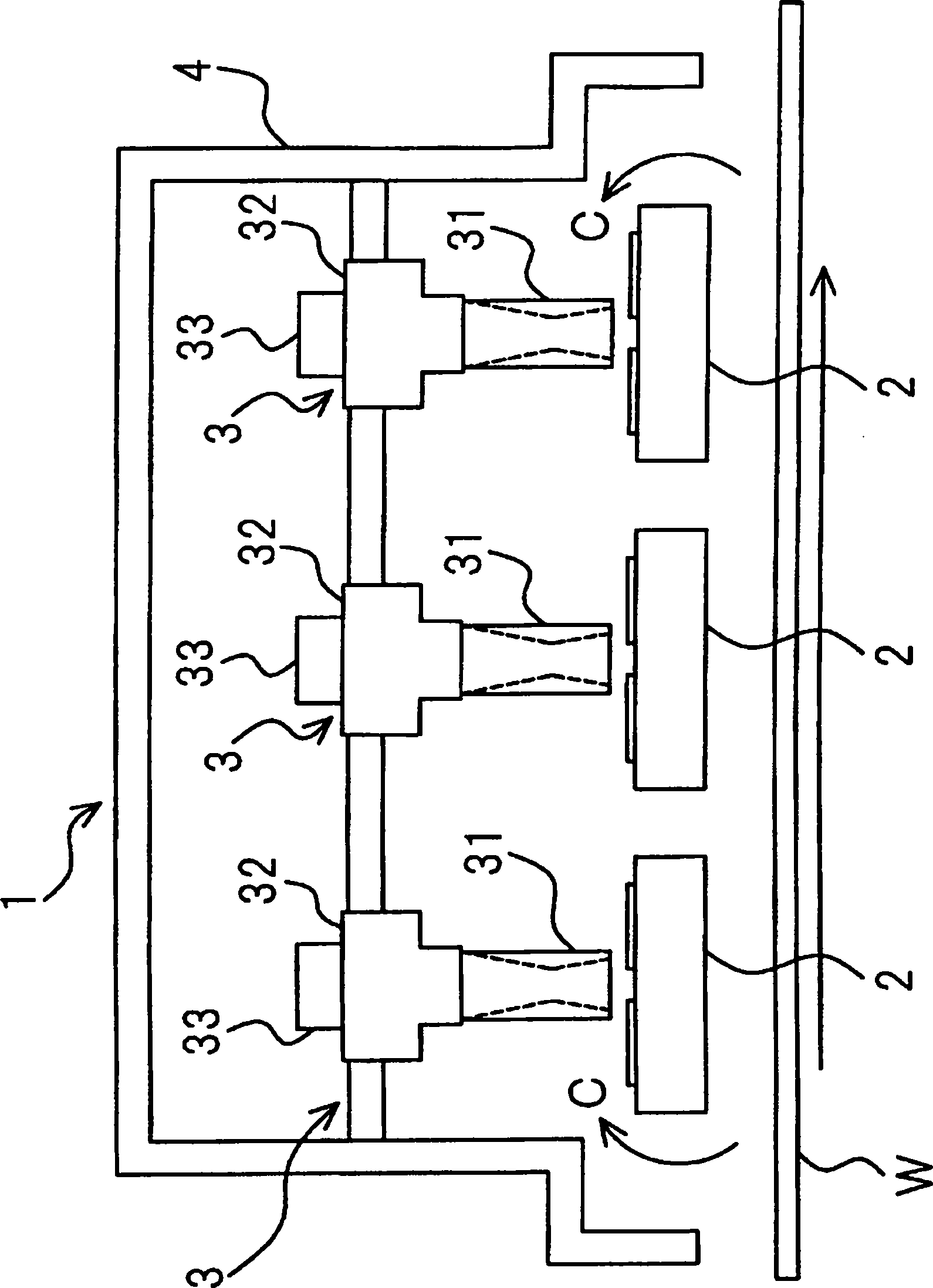

Work machine, work machine control method, program, and recording medium for same

The purpose of the invention is to cause an arm (41) and a work tool to be brought sufficiently near a boom (31) regardless of the boom (31) orientation. A work machine (1) comprises a control device(60) that sets a stroke range for an arm cylinder (42) to the side in which the arm (41) approaches the boom (31) when the boom (31) is turned in a direction away from a boom reference position (S1) depending on the boom (31) turning position such that the shortest trajectory distance (L2), which is the shortest distance between a turning trajectory (M3) of the distal end of a bucket (51) and a boom cylinder (32), is kept to a prescribed value even if the boom (31) turning position changes.

Owner:KUBOTA LTD

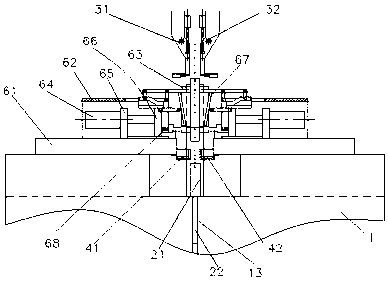

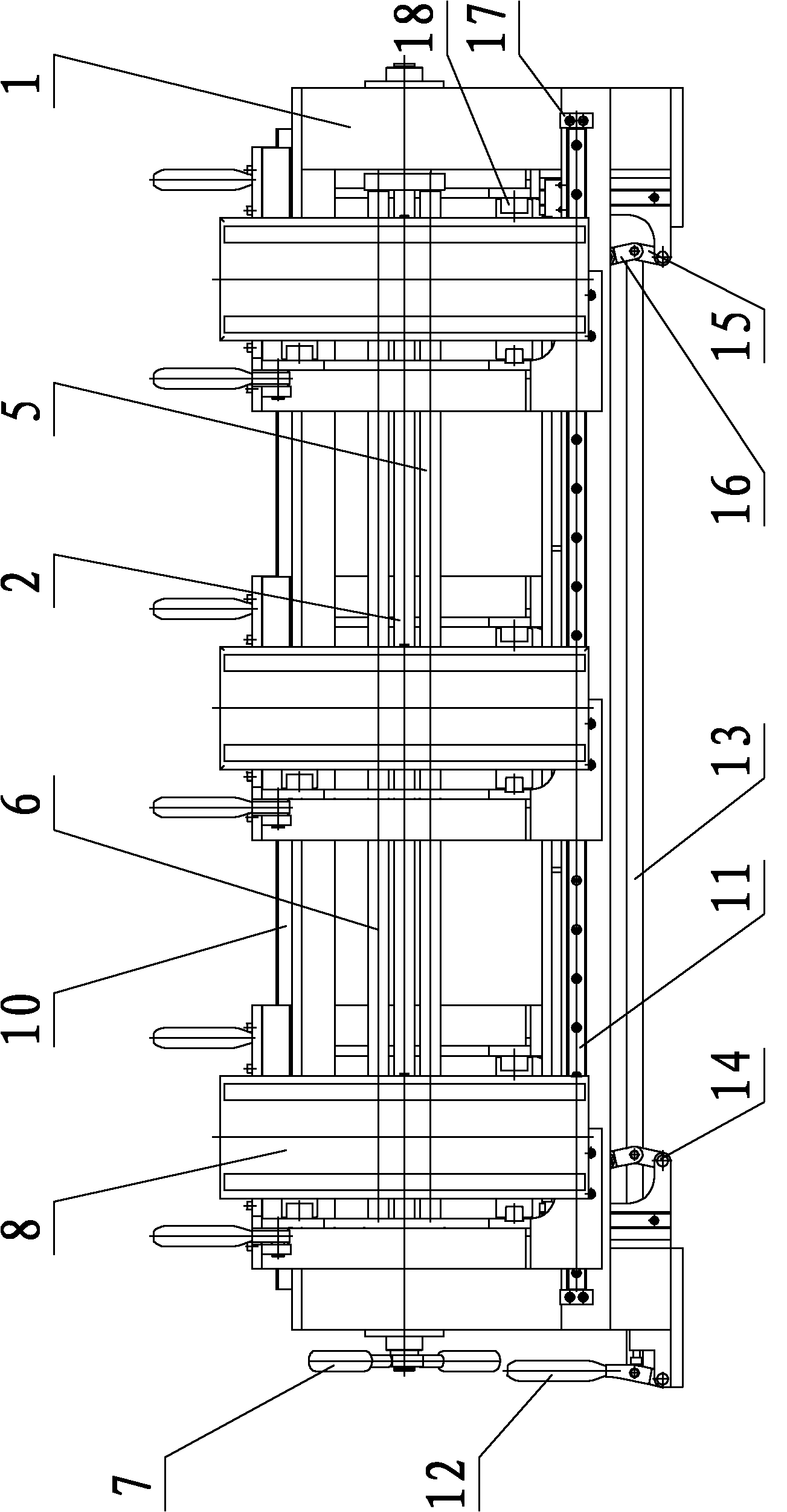

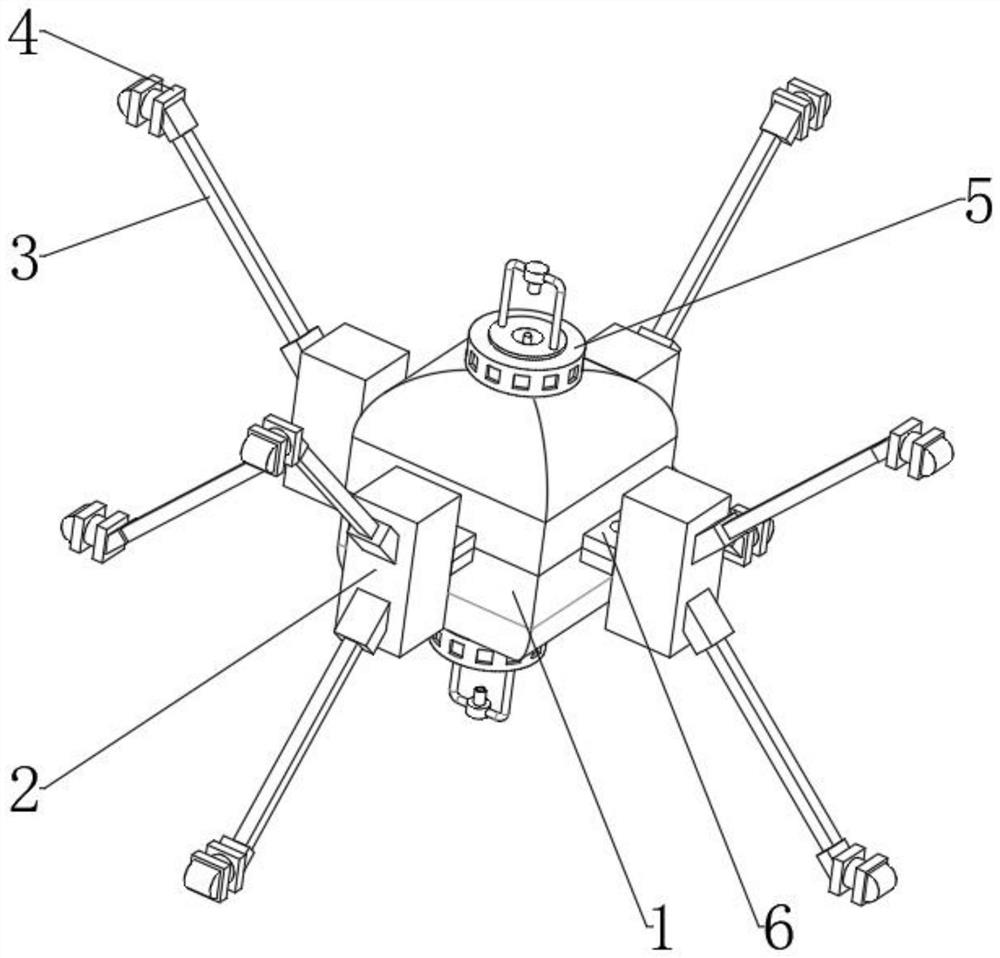

Isomagnetic adaptive positioning mechanism for multi-group laser tailor welded blanks

InactiveCN102581480BPrecise positioningRapid positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSelf adaptive

The invention relates to laser machining and positioning equipment, in particular to an isomagnetic adaptive positioning mechanism for multi-group laser tailor welded blanks, which comprises a support, a spindle, two telescopic joint arms and a plurality of magnetic layers, wherein the spindle is rotatably mounted on the support, one end of the spindle extends from the support and is connected with a first handle, the magnetic layers are evenly distributed on two sides of the spindle and reciprocate along guide rails arranged in the length direction of the support through sliders, the magnetic layers are connected with the spindle through the two telescopic joint arms, and the spindle is driven to rotate by the first handle so that the magnetic layers reciprocate along the direction perpendicular to the spindle. As the magnetic layers are capable of reciprocating axially along the spindle and along the direction perpendicular to the spindle, positioning is accurate, smoothness of laser machining is ensured, and multi-group feeding plates are rapidly positioned. The magnetic layers can be constantly close to a feeding pile, so that magnetic uniformity of the feeding pile is sufficiently ensured, difficulty in keeping feeding uniformity during multi-group welding is reduced, and feeding efficiency is improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Medical device

InactiveCN107283599AConsistent firmnessSame structureCeramic extrusion diesEngineeringUltimate tensile strength

The invention discloses a medical device which comprises a clamping device, pressing devices, a discharging device, a recycling device, a second discharging device and a shell casing. A U-shaped edge groove with an upward notch is formed in the shell casing. The second discharging device is installed in the U-shaped edge groove. The front and back sides of the upper surface of the shell casing are each provided with a guide rail in the left-right direction. The two pressing devices are of the same structure and are the left pressing device and the right pressing device. The left and right pressing devices are installed on the guide rails on the left and right sides of the upper surface of the shell casing and can slide left and right along the guide rails. The medical device is simple in structure and convenient to control and operate, and can automatically achieve discharging and improve the working efficiency, the molding quality is ensured, and meanwhile the labor intensity of workers is lowered.

Owner:耐普罗塑胶五金制品(深圳)有限公司

Improved letter box equipment

InactiveCN108215329AImprove productivityEven by forceBox making operationsPaper-makingEngineeringMechanical engineering

Owner:汪贤女

Building decorative environment-friendly board equipment

InactiveCN107415026AConsistent firmnessSame structureDischarging arrangementAuxillary shaping apparatusEngineeringUltimate tensile strength

Owner:深圳市汇呈实业有限公司

a medical device

InactiveCN107283599BConsistent firmnessSame structureCeramic extrusion diesEngineeringUltimate tensile strength

The invention discloses a medical device which comprises a clamping device, pressing devices, a discharging device, a recycling device, a second discharging device and a shell casing. A U-shaped edge groove with an upward notch is formed in the shell casing. The second discharging device is installed in the U-shaped edge groove. The front and back sides of the upper surface of the shell casing are each provided with a guide rail in the left-right direction. The two pressing devices are of the same structure and are the left pressing device and the right pressing device. The left and right pressing devices are installed on the guide rails on the left and right sides of the upper surface of the shell casing and can slide left and right along the guide rails. The medical device is simple in structure and convenient to control and operate, and can automatically achieve discharging and improve the working efficiency, the molding quality is ensured, and meanwhile the labor intensity of workers is lowered.

Owner:耐普罗塑胶五金制品(深圳)有限公司

Construction method of imitation cave decorative surface

ActiveCN105155847BSave man hoursShorten the timeCovering/liningsBuilding material handlingSurface layerStructure of the Earth

Owner:SHANGHAI GARDEN ENG CO LTD

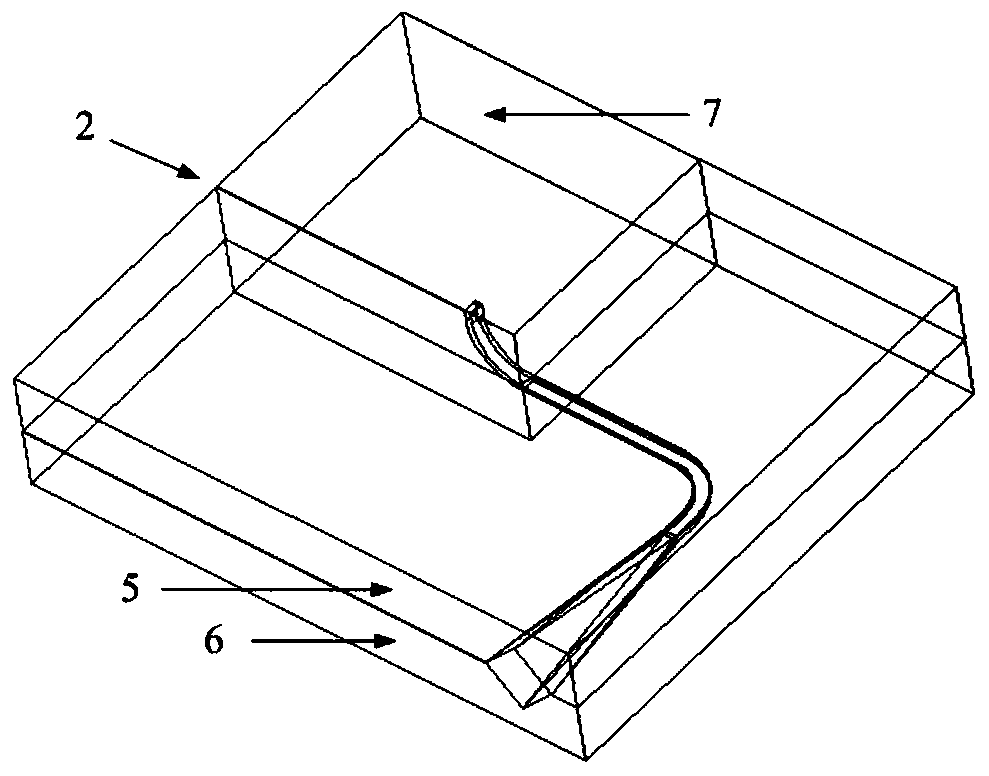

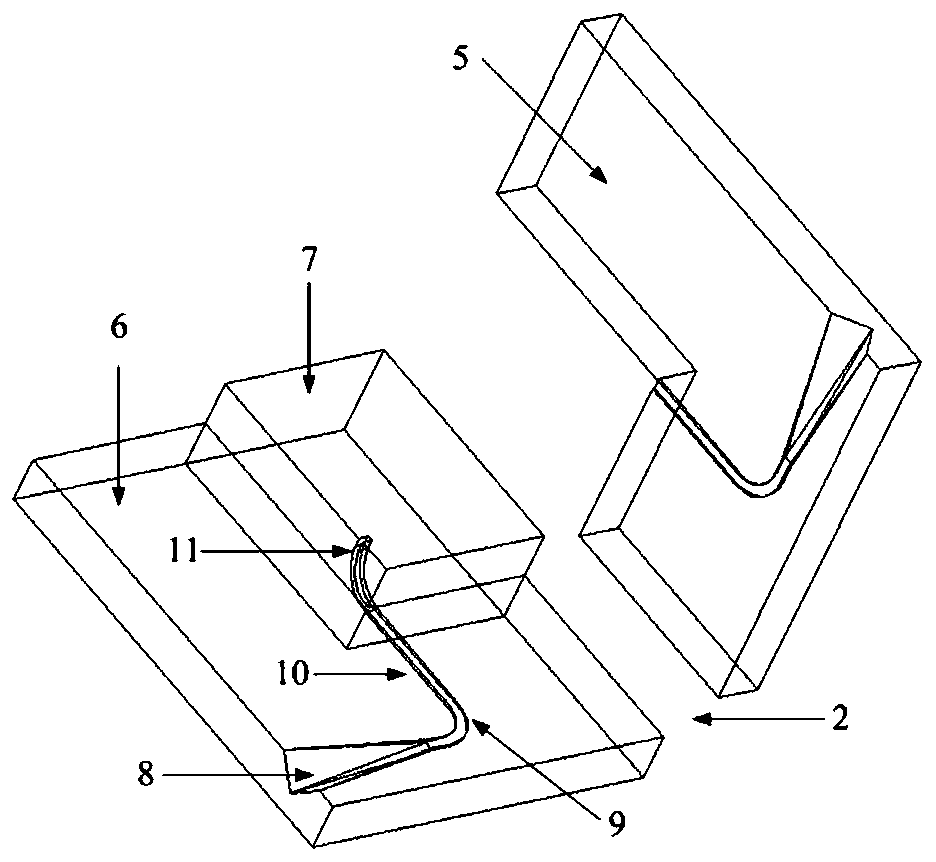

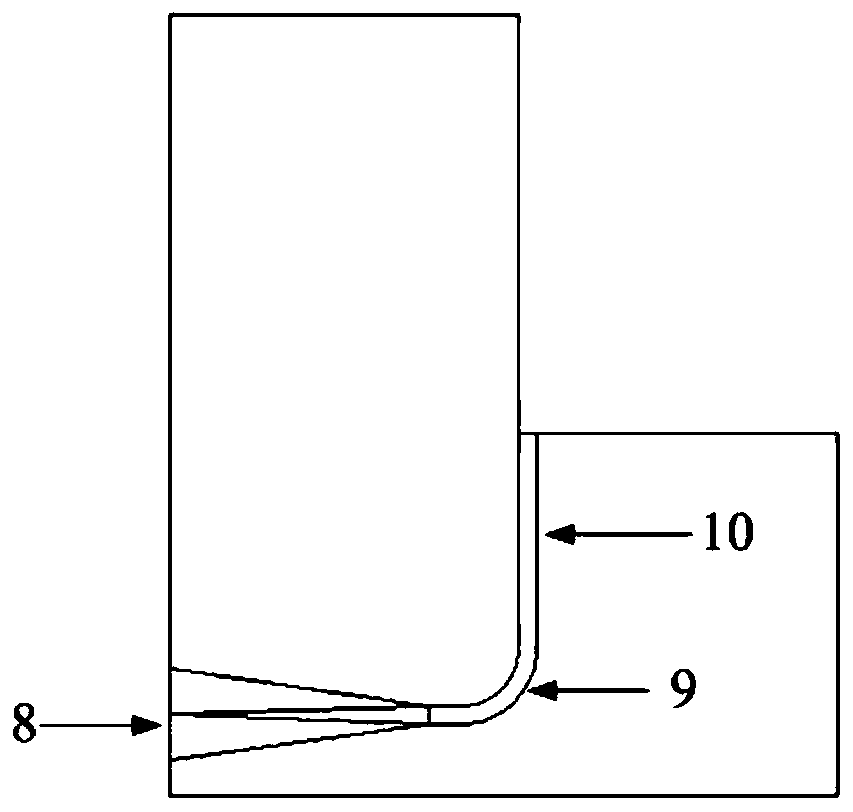

A Terahertz Antenna for Short Baseline Measurements

The invention discloses a terahertz antenna for realizing short baseline measurement. The antenna is a horn antenna (2); the horn antenna (2) is a rectangular solid cavity composed of an upper half cavity (5), a lower half cavity (6) and a middle cavity (7); ditches of the upper half cavity (5) and the lower half cavity (6) are symmetric; the upper half cavity (5) comprises an upper half part of a horn mouth surface (8), an upper half part of a transverse turning waveguide (9) and an upper half part of an output waveguide (10); the lower half cavity (6) comprises the lower half part of the horn mouth surface (8), the lower half part of the transverse turning waveguide (9) and the lower half part of the output waveguide (10); and the middle cavity (7) comprises a lengthways turning waveguide (11). The terahertz antenna disclosed by the invention has the characteristics of a simple structure, reliable performances and a capability of realizing short baseline measurement.

Owner:NAT SPACE SCI CENT CAS

Mobile mining flameproof and intrinsically safe control box

ActiveCN113473755ABig spaceClose enoughClosed casingsCasings/cabinets/drawers detailsIntrinsic safetyStructural engineering

The invention discloses a mobile mining flameproof and intrinsically safe control box, and belongs to the technical field of mining control equipment. The control box comprises two oppositely mounted shells, an erecting table fixedly connected to the peripheral outer walls of the shells and a central control box arranged in the shells, and a mobile assembly is fixedly connected to the outer wall of one side of the erecting table. A buffer assembly comprises a fixed sleeve fixedly connected to the inner wall of the top of the shell and an inner connecting sleeve fixedly connected to the outer wall of the top of the fixed sleeve, the inner connecting sleeve and the inner wall of the fixed sleeve are slidably connected with an inner cylinder, sliding grooves are formed in the inner wall of the periphery of the fixed sleeve, and springback rods are fixedly connected to the inner walls of the tops of the sliding grooves. By arranging the buffer assembly, a high-temperature and high-pressure gas in the inner connecting sleeve and the shell can be treated, meanwhile, the space in the shell is extended and expanded by means of movement of the inner cylinder, the gas pressure is reduced, and the inner cylinder is slidably connected to the inner wall of the inner connecting sleeve so that the shell keeps sufficient sealing performance.

Owner:宿州科力电器有限公司

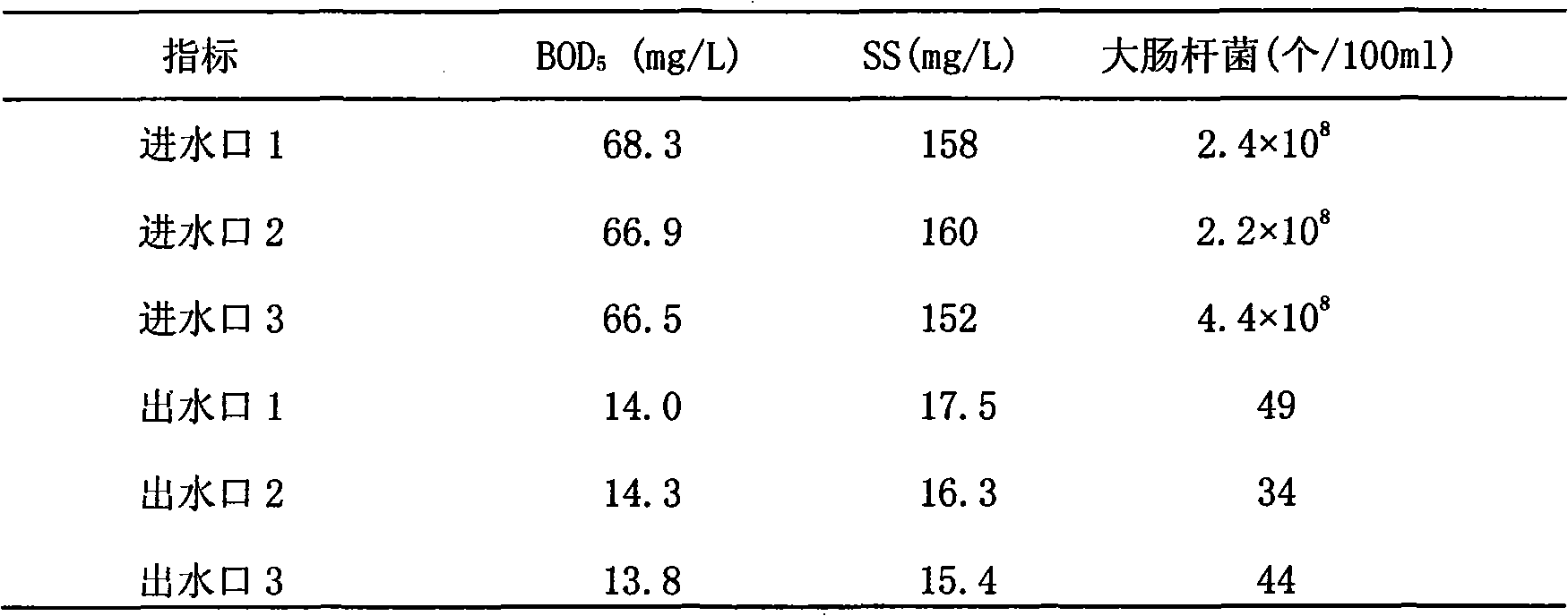

Modified PVC biologic filler

InactiveCN101628758BImprove hydrophilicityGood flexibilitySustainable biological treatmentBiological water/sewage treatmentElastomerPolyvinyl alcohol

The invention discloses a modified PVC biologic filler comprising the following components according to part by weight: 4-6 parts of polyvinyl alcohol, 2-4 parts of polyethylene glycol octyl phenyl ether, 2-4 parts of stearic acid, 0.5-1.5 parts of polyacrylamide, 1-3 parts of active carbon, 4-6 parts of magnetic powders and 66.5-79.5 parts of PVC elastomers. The invention mainly carries out hydrophilic modification, active carbon modification, magnetic modification and toughening modification on the PVC biologic filler, enhances the hydrophilic performance and the flexible performance of thebiologic filler, prolongs the contact time of microorganisms and organic substances and further induces the activity of the microorganisms. The obtained microorganism filler enables the biologic filler to have high film hanging speed and large film hanging quantity, and enable a film and the filler to have sufficient compactness. The obtained biologic filler has better heat resisting performance,difficult aging and strong shock resistance capability.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

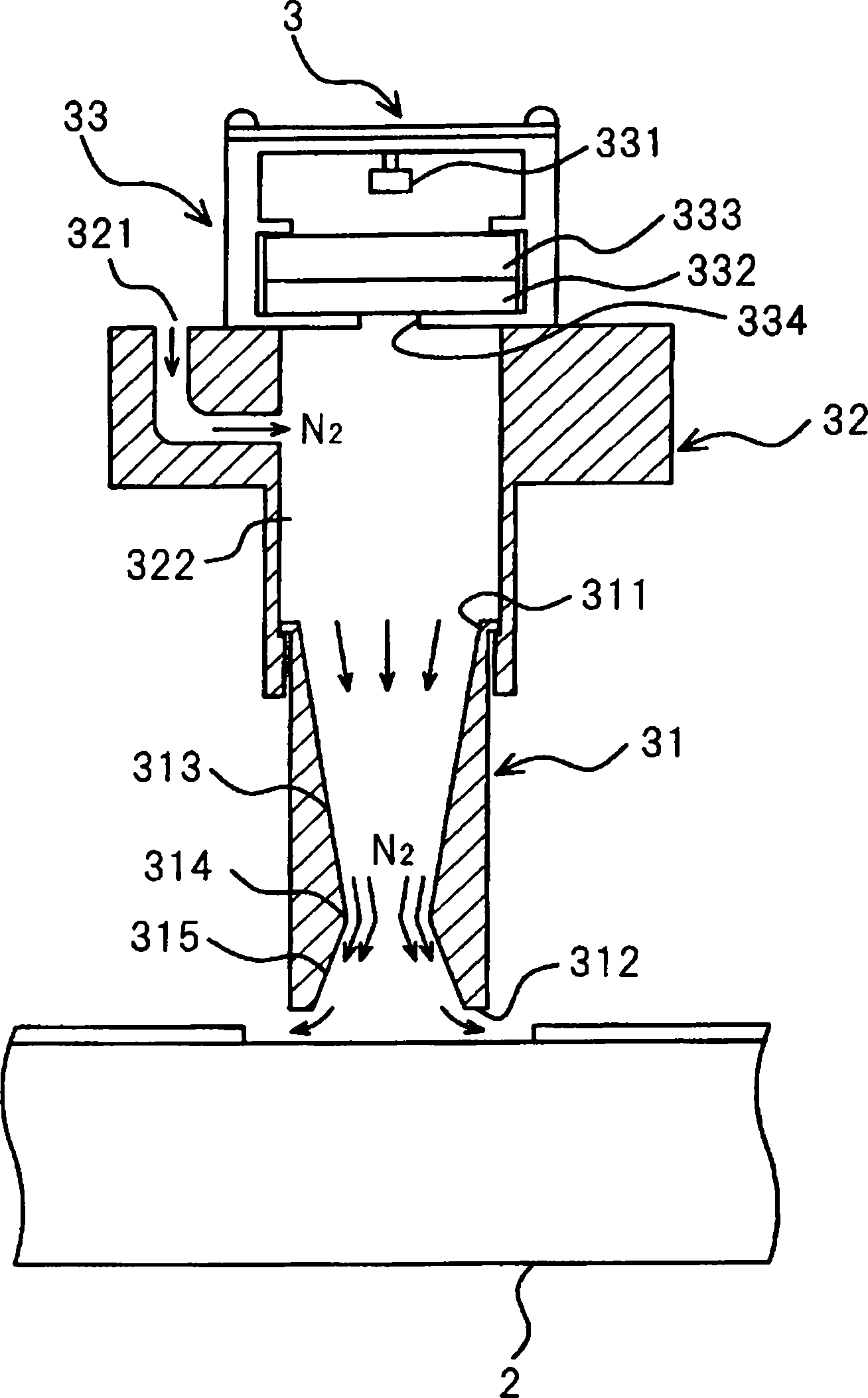

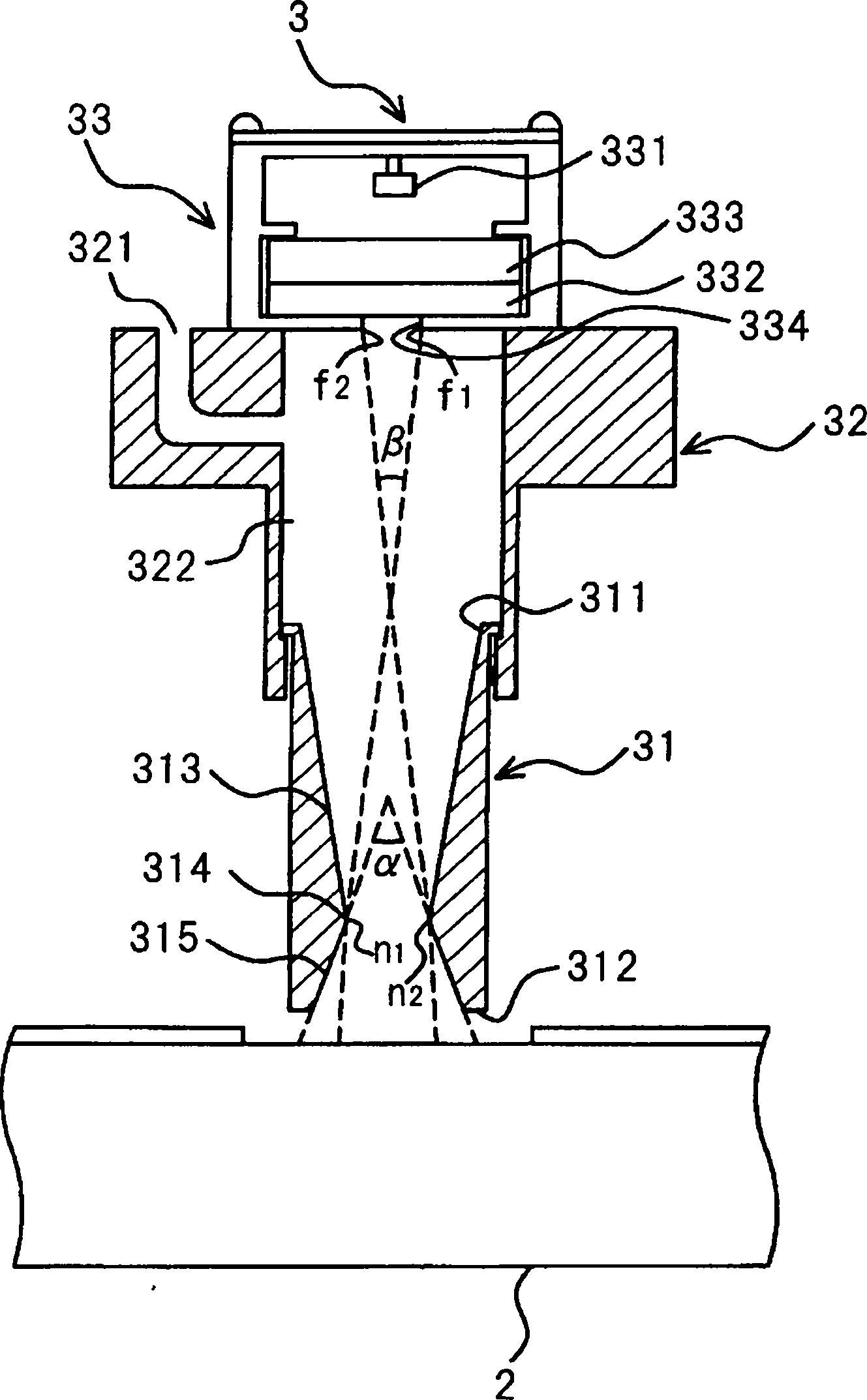

Excimer lamp apparatus

ActiveCN101714497BIncrease flow rateClose enoughElectric discharge tubesElectric lighting sourcesUltravioletExcimer laser

PURPOSE: An excimer lamp apparatus can control the measured value change of the ultraviolet ray by the convection of atmosphere by emitting so that the flow of the inactive gas spreads out from the opening of the cylindrical form part to the excimer lamp to the aperture circumference. CONSTITUTION: An optical sensor(3) comprises the light monitor part, and the cylindrical form part and frame part. The light monitor part comprises the photo diode and fluorescent substance. A cylindrical form part(31) comprises the light monitor part and the opening opened to the excimer lamp. The frame part(32) interlinks the light monitor part and cylindrical form part.

Owner:USHIO DENKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com