Building decorative environment-friendly board equipment

A technology for architectural decoration and environmental protection, applied in auxiliary forming equipment, unloading device, forming pressure head, etc., can solve the problems of low processing production efficiency and complicated manufacturing process, and achieve the effects of improving productivity, consistent compactness, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

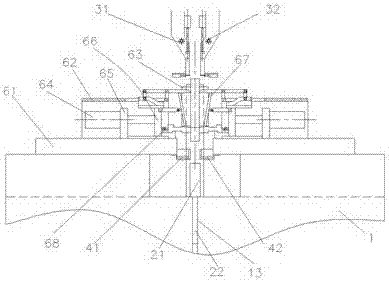

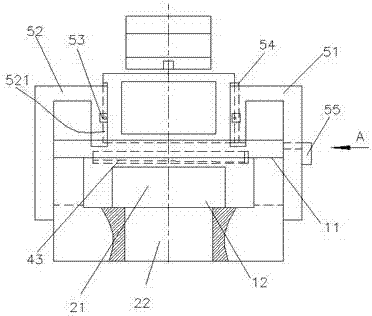

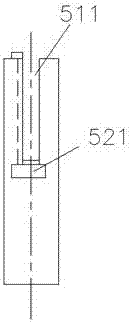

[0035] Such as Figure 1-Figure 14 As shown, the environmental protection panel equipment for building decoration of the present invention includes a clamping device, a compacting device, a dismounting device, a collecting device, a second dismounting device, and a seat body 1. The seat body 1 is provided with an opening U The second dismounting device is installed in the U port, and the front and rear sides of the upper surface of the seat body 1 are each provided with a guide rail 11 in the left and right directions. The compaction device has two sets of the same structure, and the left compaction The device and the right compaction device are respectively installed on the guide rails 11 on the left and right sides of the upper surface of the seat body 1 and can slide left and right along the guide rails 11. The upper surface of the seat body 1 has a front and back In the channel 12, there is a sliding groove 13 in the vertical direction. The removal device includes two first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com