Improved letter box equipment

An improved letterbox technology, which is applied to paper/cardboard containers, container manufacturing machinery, box production operations, etc., can solve the problems of low processing efficiency and achieve the effects of improving productivity, consistent compactness, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

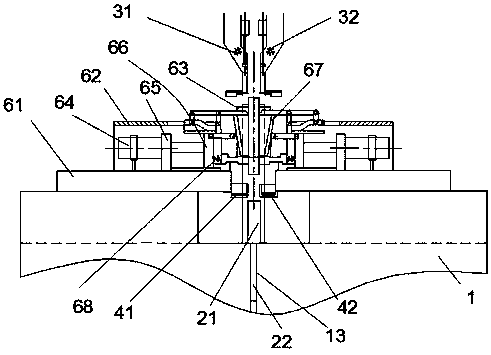

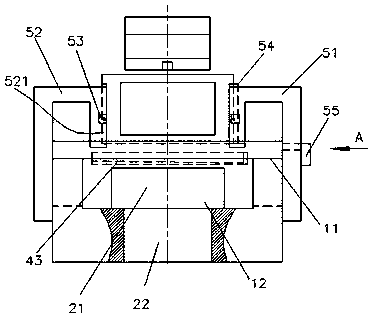

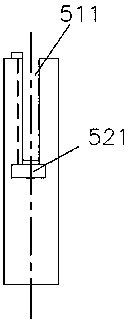

[0036] Such as Figure 1-Figure 14 As shown, an improved letterbox device of the present invention includes a clamping device, a profiling device, a discharge device, a retracting device, a second discharge device and a base 1, and the base 1 is provided with a cavity with an upward U cavity , the second discharge device is installed in the U cavity, and the front and rear sides of the upper surface of the base 1 are respectively provided with a slide rail 11 in the left and right directions. The profiling device has two groups with the same structure, and the left profiling device and the right pressing device, which are respectively installed on the slide rails 11 on the left and right sides of the upper surface of the base 1 and can slide left and right along the slide rails 11. Through cavity 12, a sliding cavity 13 in the up and down direction is arranged in the through cavity 12, and the discharge device includes two first discharge elements 31 and second discharge eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com