Novel bipolar battery panel pressing formation device

A technology of pressing and forming devices, which is applied to the construction of batteries with bipolar electrodes, lead-acid batteries, and lead-acid batteries. It can solve the problems of complex manufacturing, high process requirements, and high costs, and achieve consistent compactness, Uniform distribution of materials and improvement of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

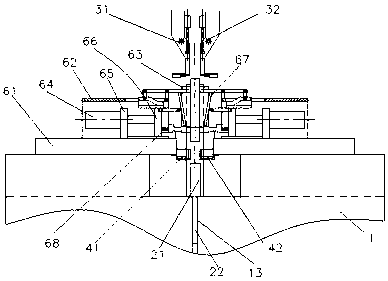

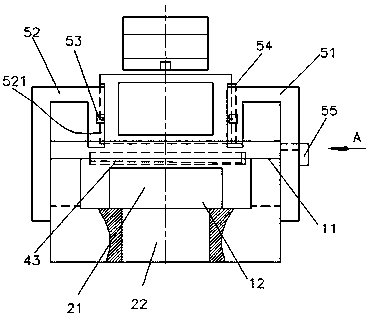

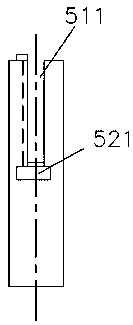

[0036] Such as Figure 1-Figure 14 As shown, a new type of bipolar battery plate pressing forming device of the present invention includes a substrate clamping device, a forming device, a blanking device, a residual material collecting device, a second blanking device, and a frame 1. The frame 1 is provided with a U-slot with an opening upward, the second blanking device is installed in the U-slot, the front and rear sides of the upper surface of the frame 1 are each provided with a left-right guide rail 11, the forming device has the same structure Two groups, the left forming device and the right forming device, are respectively installed on the guide rails 11 on the left and right sides of the upper surface of the frame 1 and can slide left and right along the guide rails 11. The middle part of the upper surface of the frame 1 A rectangular through groove 12 in the front and rear direction is provided, and a sliding groove 13 in the up and down direction is provided in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com