Fuel injector

A technology of fuel injectors and fuels, which is applied in the direction of fuel injection devices, special fuel injection devices, charging systems, etc., and can solve problems such as complex removal of matching pins, breaking or shearing, and damage to matching pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

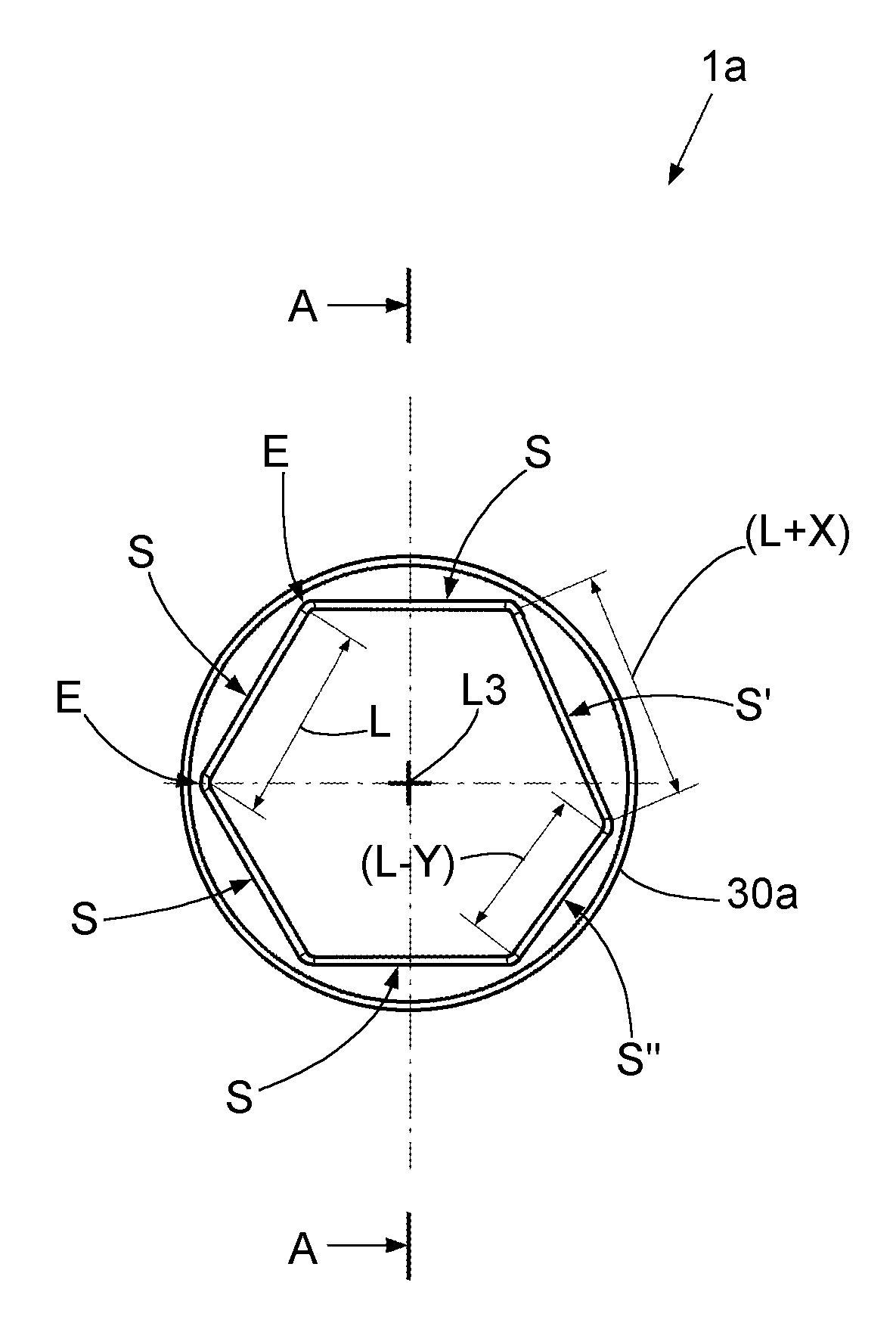

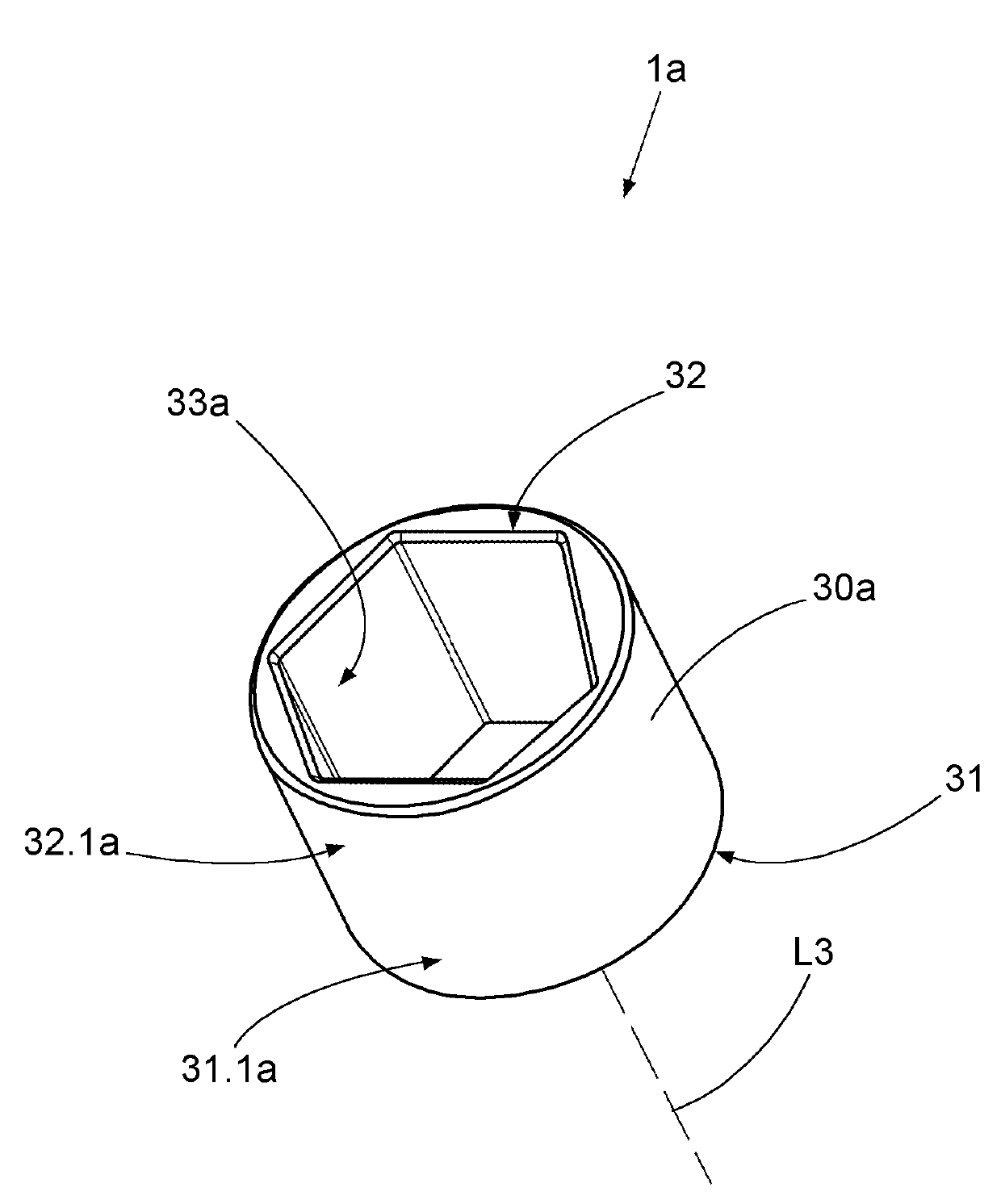

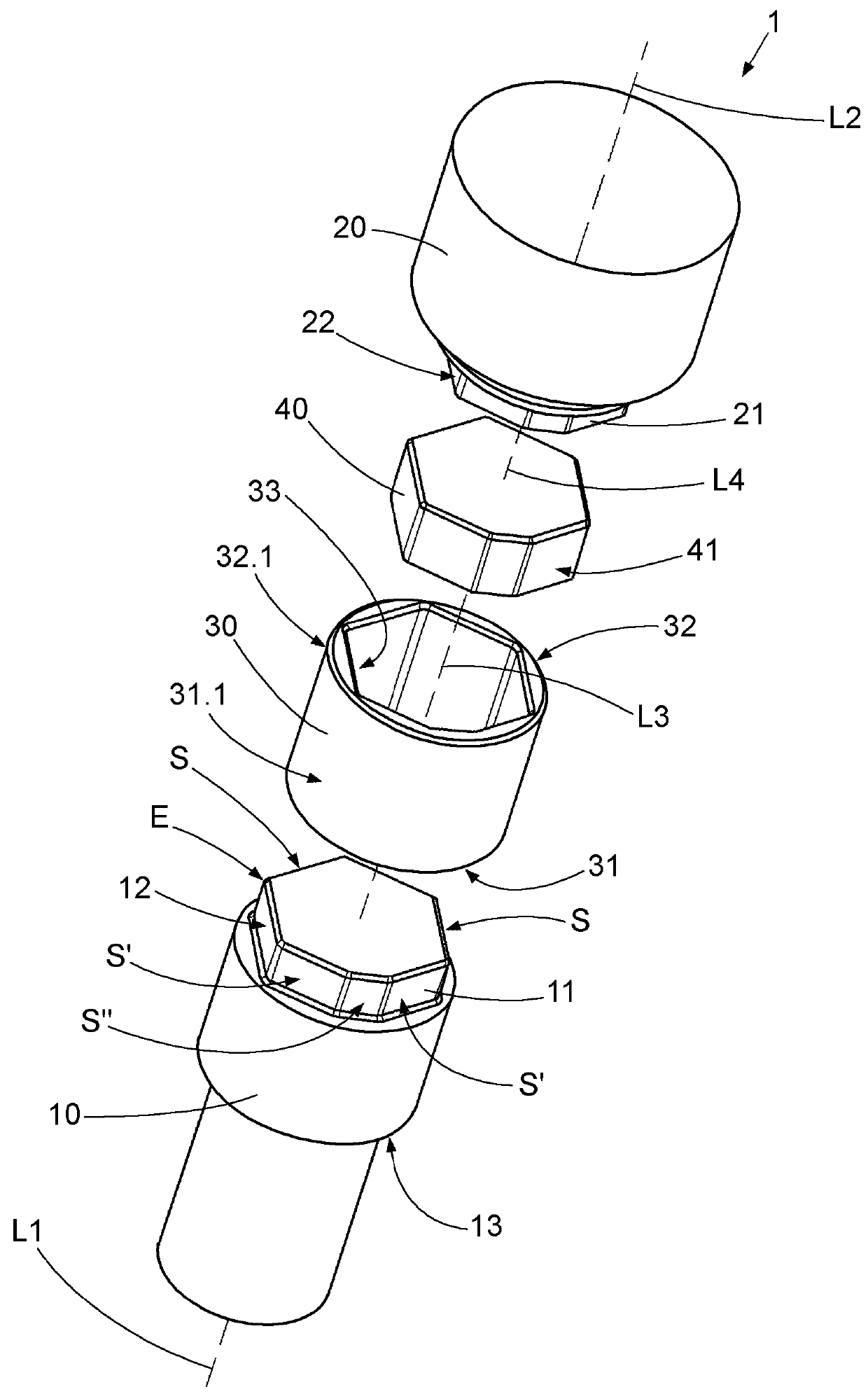

[0072] figure 1 A perspective exploded view of a fuel injector 1 designed according to a first embodiment of the invention of an internal combustion engine (not shown in its entirety), here designed as a marine diesel engine, is shown.

[0073] The fuel injector 1 has an injection nozzle 10 for injecting fuel (here diesel), a switching valve 20 for controlling (enabling / blocking) the injection of fuel and a connecting sleeve arranged between the injection nozzle 10 and the switching valve 20 barrel or centering sleeve 30.

[0074] The injection nozzle 10 has a predetermined nozzle outer contour 12 at its longitudinal end section 11 facing the connecting sleeve 30 , while the switching valve 20 has a predetermined nozzle outer contour 12 at its longitudinal end section 21 facing the connecting sleeve 30 . Determined valve outer contour 22 .

[0075] The connecting sleeve 30 has, for its part, a predetermined inner sleeve contour 33 , into which the spray nozzle 10 with its no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com