Construction method of cave-imitating decorative surface

A decorative surface layer and construction method technology, applied in the construction field of imitation cave decorative surface layer, can solve the problems of difficult to control effect, low construction difficulty, uneven effect, etc., and achieve the effect of reducing labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

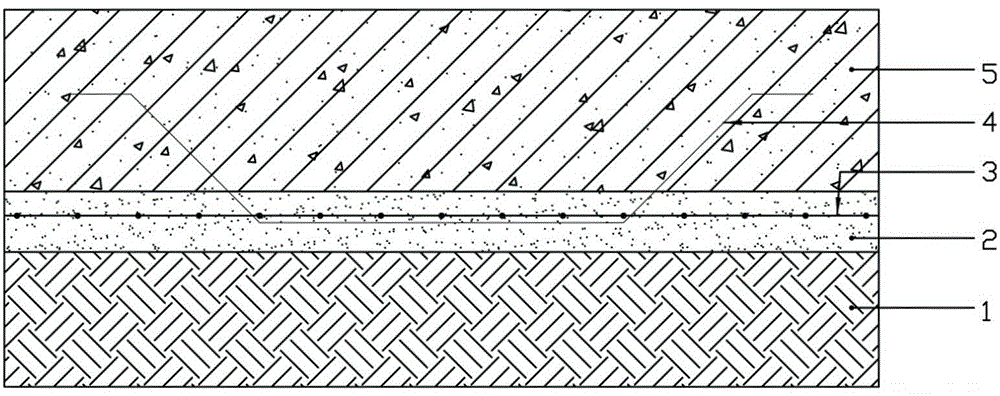

[0027] see figure 1 , a construction method for imitating a cave decorative surface of the present invention is characterized in that it comprises,

[0028] 1) Shaping the cave soil mold 1 inside the structure;

[0029] 2) To make the decorative surface layer, first apply a layer of mortar 2 on the surface of the soil mold 1, and then lay steel wire mesh 3 and tie bars 4 in the mortar, and the two ends of the tie bars 4 extend into and fasten the steel wire mesh 3. After setting, apply the second layer of mortar; or, add the steel wire mesh 3 with pre-embedded tie bars into the mortar, and wait for the mortar to solidify;

[0030] 3) Binding steel bars and making side forms on the outside of the mortar according to the designed configuration, and then pouring reinforced concrete or steel fiber concrete to form the concrete structure layer 5;

[0031] 4) After the concrete structure layer is solidified and stabilized, the internal soil mold 1 is hollowed out, and the inner wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com