Lengthened piston mechanism for visual optical engine device

An optical engine and piston mechanism technology, which is applied to the sealing device of the engine, engine components, machines/engines, etc., can solve the problem of inability to observe, and achieve the effect of avoiding collision with the cylinder liner, reducing wear, and lengthening the coaxiality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

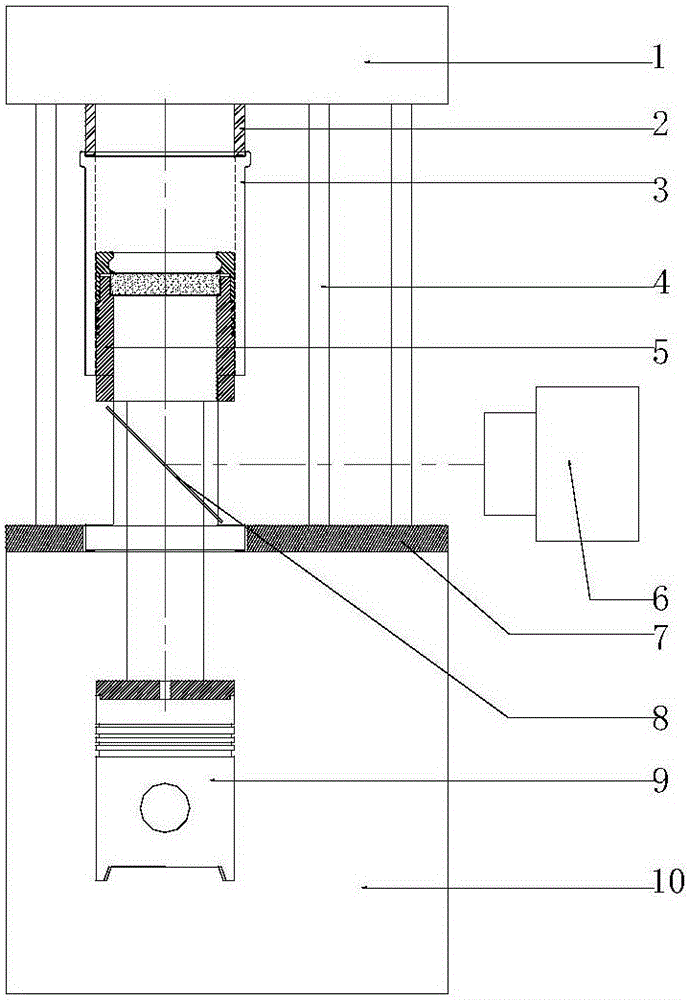

[0020] combine figure 1 , 2 , an extended piston 5 for a visual optical engine device of the present invention includes a cylinder head 1, an extended piston 5, an original piston 9, a cylinder body 10, and the like.

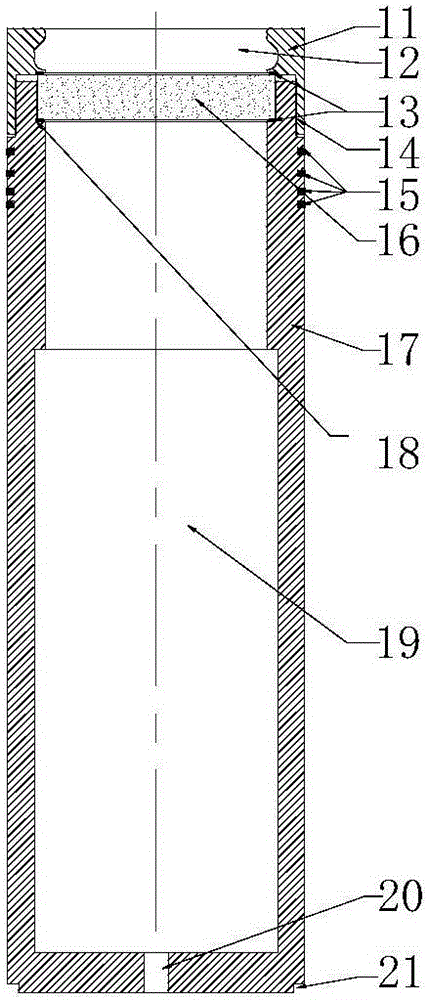

[0021] Extended piston 5 is made up of two parts of piston cover 11 and extended piston body part 17, and piston cover 11 comprises pit 12 and thread 14, and extended piston comprises thread 14, piston ring 15, round table 18, square through hole 19, through hole 20 and Boss 21.

[0022] The piston cover 11 and the extended piston main body 17 are connected through a screw thread 14 structure. By designing the shape of the pit 12, the shape of the piston cover 11 can be designed into various combustion chamber shapes. Simultaneously, a valve avoidance pit can be set on the piston cover 11, and the optical engine compression ratio can be changed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com