Light transmission module, electronic device, and manufacturing method of light transmission module

A technology for electronic equipment and optical transmission, which is applied to the coupling of optical waveguides, light guides, optics, etc., and can solve the problems of large-design light-emitting and receiving elements 13, increased occupied area of optical transmission modules, and increased costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

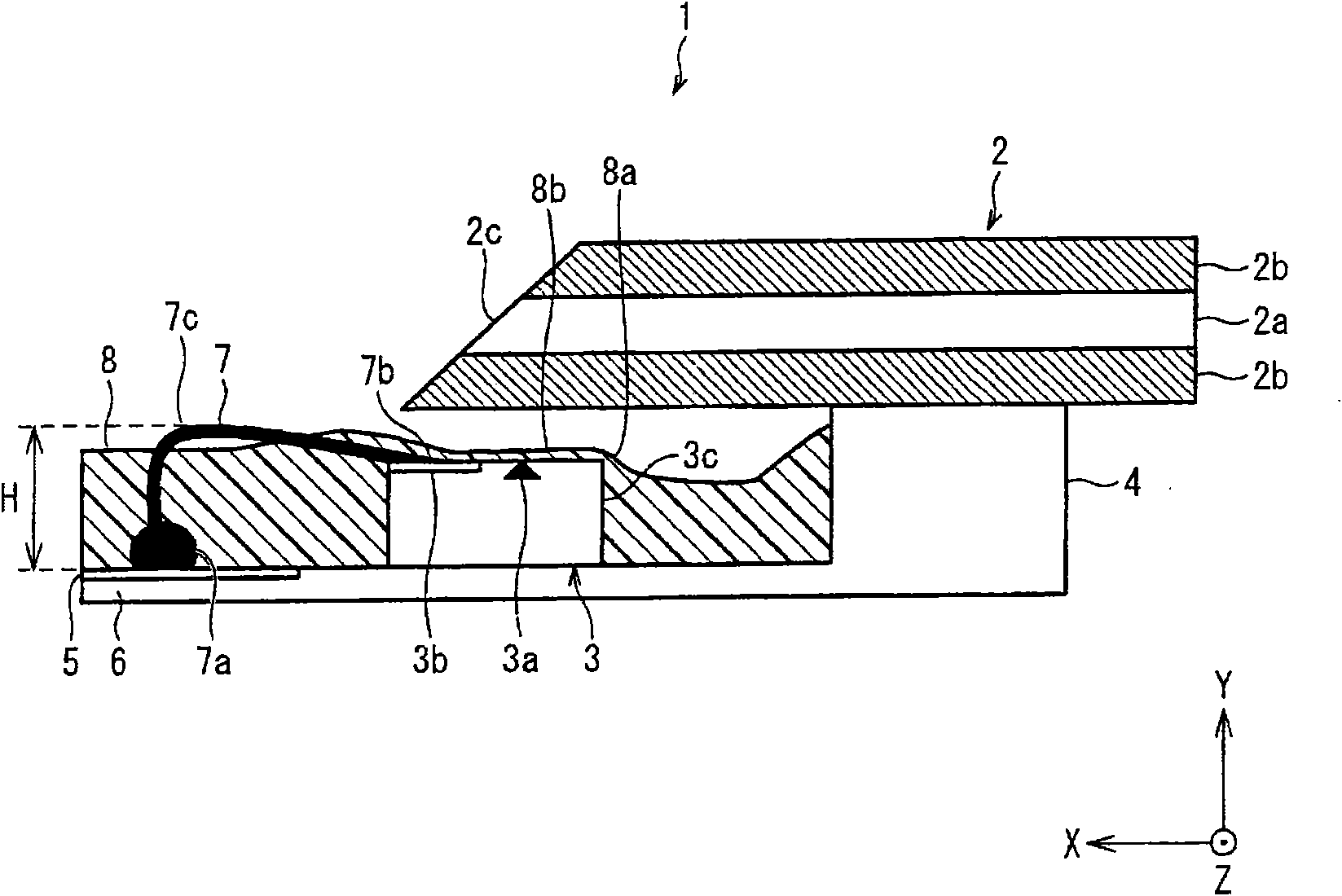

[0130] In the configuration of the optical transmission module 1 of the embodiment of the present invention, for figure 1 A modified example of the configuration shown will be described. Figure 5 is a cross-sectional view showing a schematic result of the optical transmission module according to Modification 1. FIG. In addition, in Figure 5 In , in order to simplify the structure of Modification 1, the thin film optical waveguide 2 is omitted.

[0131] Such as Figure 5 As shown, the optical transmission module 1 of Modification 1 has dummy pads 9 a and 9 b. The dummy pads 9 a and 9 b are provided on the surface of the substrate 6 opposite to the surface on which the light emitting and receiving elements 3 are mounted. The dummy pads 9 a are arranged so as to overlap the connection portions where the substrate wiring 5 and the bonding wiring 7 are connected when projected onto a plan view. In addition, the dummy pads 9b are arranged to overlap with the light emitting a...

Deformed example 2

[0138] In the configuration of the optical transmission module 1 according to the embodiment of the present invention, the figure 1 A modified example of the configuration shown will be described. Image 6 is a cross-sectional view showing a schematic configuration of an optical transmission module according to Modification 2.

[0139] Such as Image 6 As shown, in the optical transmission module 1 of Modification 2, the front end 2d of the thin-film optical waveguide 2 in the light transmission direction (X direction) is arranged at the contact point (end 7b) of the bonding wire 7 with the electrode pad 3b and the light emitting and receiving terminal. Between points 3a. The thin-film optical waveguide 2 is held by the height compensating member 4 and has an optical path conversion mirror portion 2 c whose at least one end portion is obliquely processed. Furthermore, the front end portion 2d may also be referred to as the light transmission direction front end of the opti...

Deformed example 3

[0144] In the structure of the optical transmission module 1 of the embodiment of the present invention, for figure 1 Modifications of the shown configurations will be described. As described above, the optical transmission path to which the present invention is applicable is not limited to a thin-film optical waveguide, and may be any member as long as it has a function of transmitting light. The optical transmission module 1 of Modification 3 has an optical fiber or a lens as an optical transmission path. first, Figure 7 It is a cross-sectional view showing a schematic configuration of an optical transmission module 1 having an optical fiber as an optical transmission path.

[0145] Such as Figure 7 As shown, the optical fiber 21 is formed of a core 21a having a high refractive index and a cladding 21b having a small refractive index provided in contact with the periphery of the core 21a. The optical fiber 21 repeats total reflection and transmission of an optical sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com