Equipment for stirring standing grain and threshing

A threshing device, a new type of technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problem of the closeness of grain (wheat) ears to the threshing device, etc., and achieve a significant threshing effect and prolong the threshing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

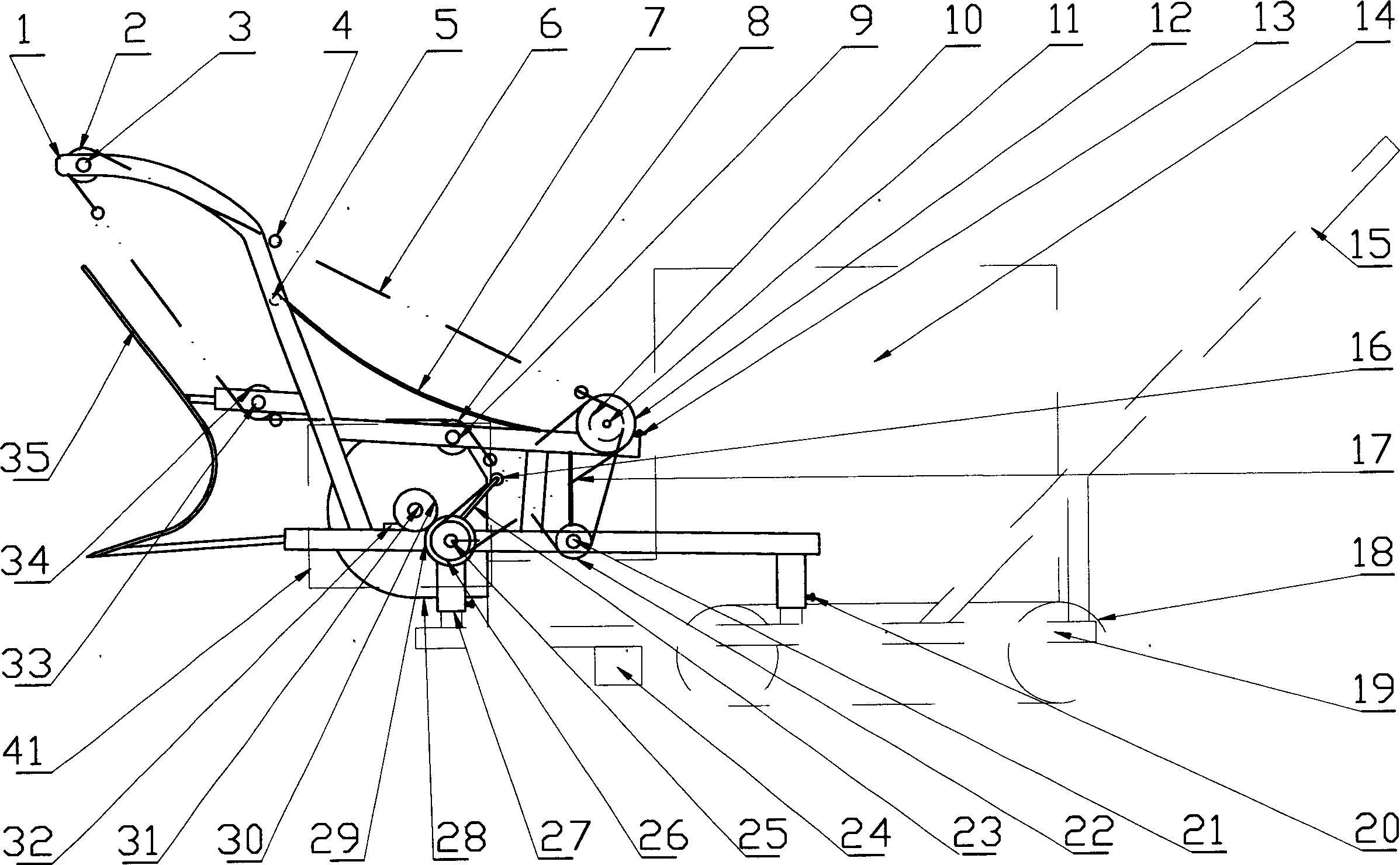

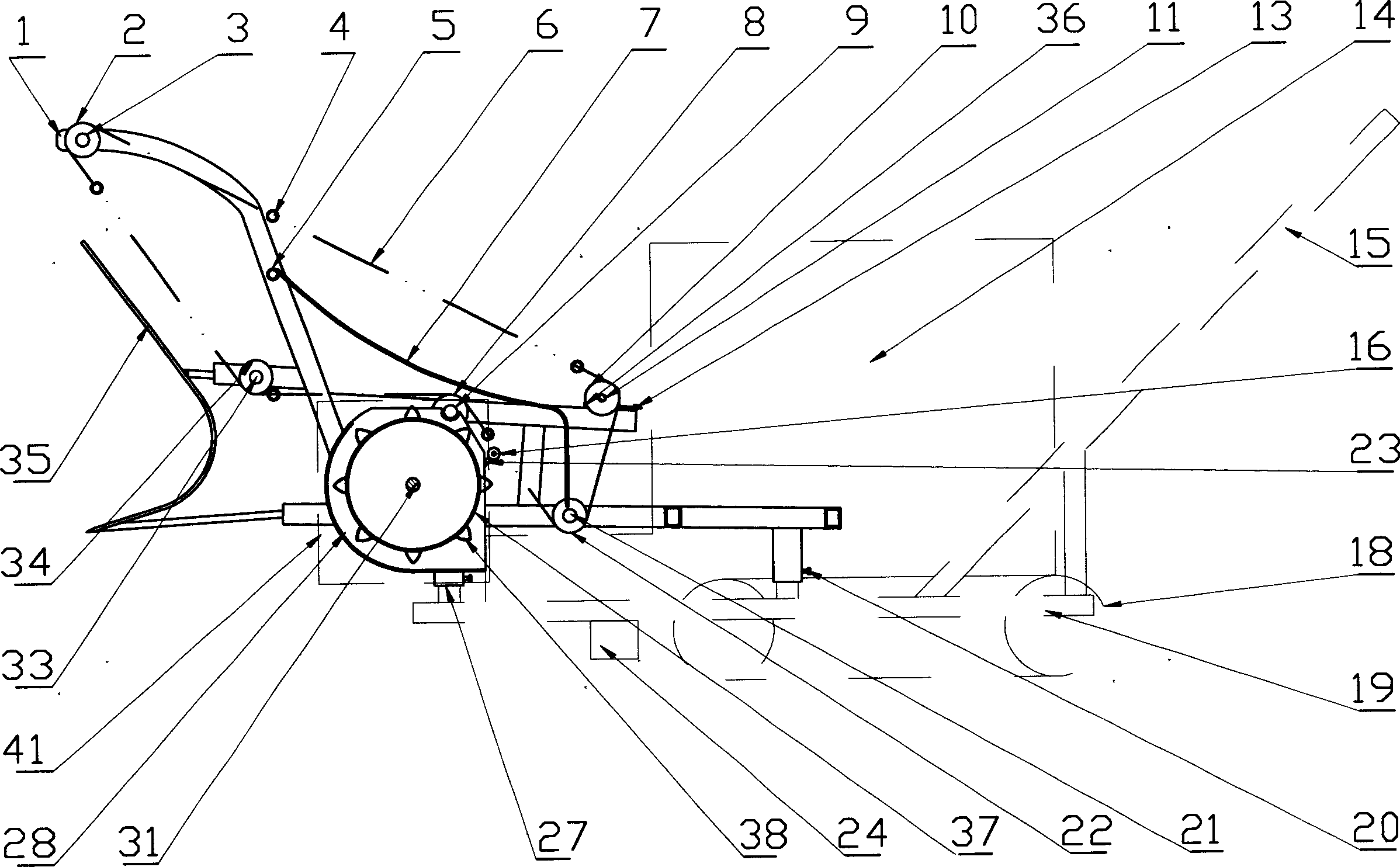

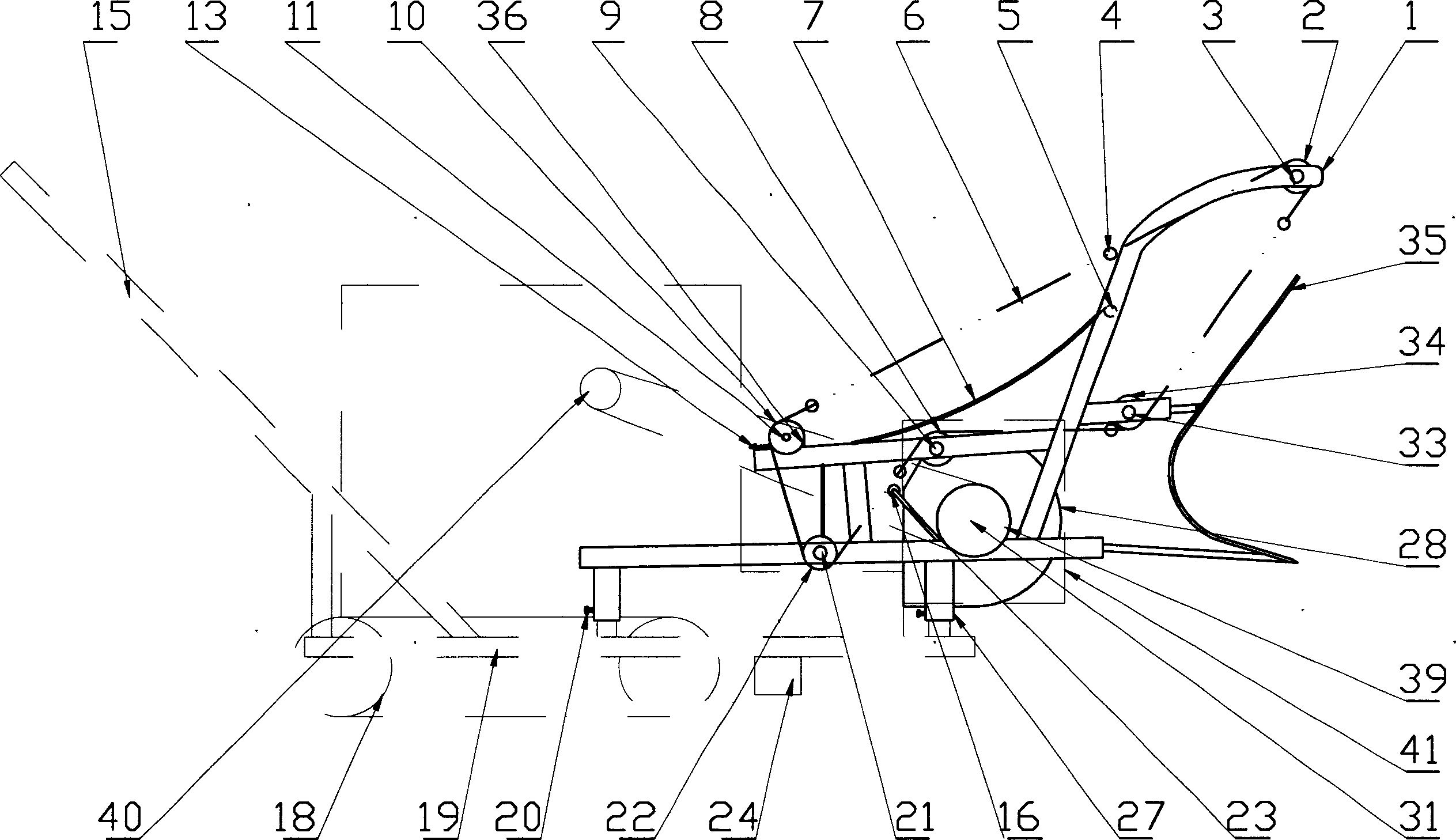

[0013] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] This embodiment includes a reeling frame 1, a grain retaining cover 7, a threshing system 41 and a flexible reeling device.

[0015] The reeling frame 1 is front and rear symmetry, and its front and rear side shapes are Shaped, the left side is cantilever-shaped, and there is a cross bar 5 connecting the front and rear cantilevers in the middle and upper part of the cantilever; on the right side of the lower part, there are two cross bars that connect the front and rear sides of the frame as a whole; the lower part has four The pin 27 that hollow tube is made, every pin is equipped with adjusting set screw 20.

[0016] Keeping the grain cover 7 is " factory " word shape inverted to the right, and its left end is built on the cross bar 5, and the lower right part is contained in the middle part of the reeling frame 1 bottom right position.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com