Detergent box siphon structure, detergent box and washing equipment

A technology for detergent boxes and washing equipment, which is applied to washing devices, other washing machines, textiles and papermaking, etc., and can solve the problems of continuous siphon and the siphon effect cannot be automatically interrupted immediately, so as to increase the suction force and avoid the problem of continuous siphon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

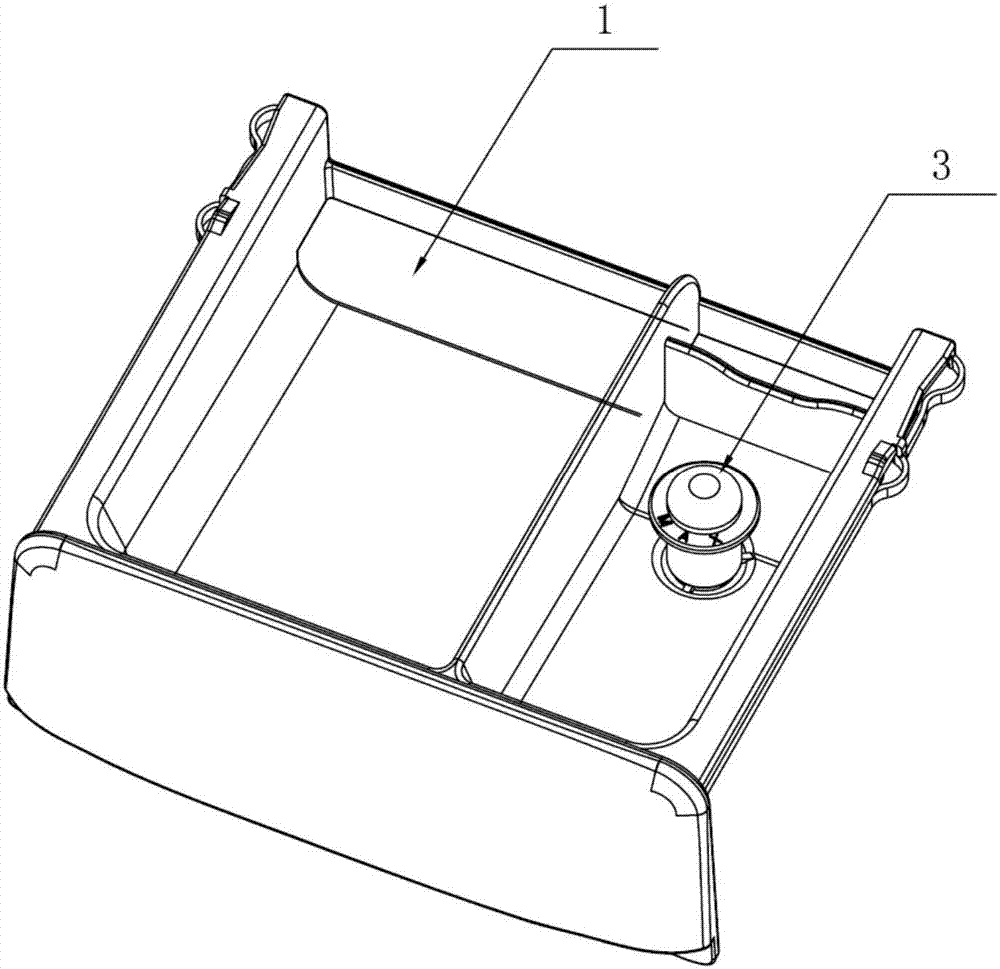

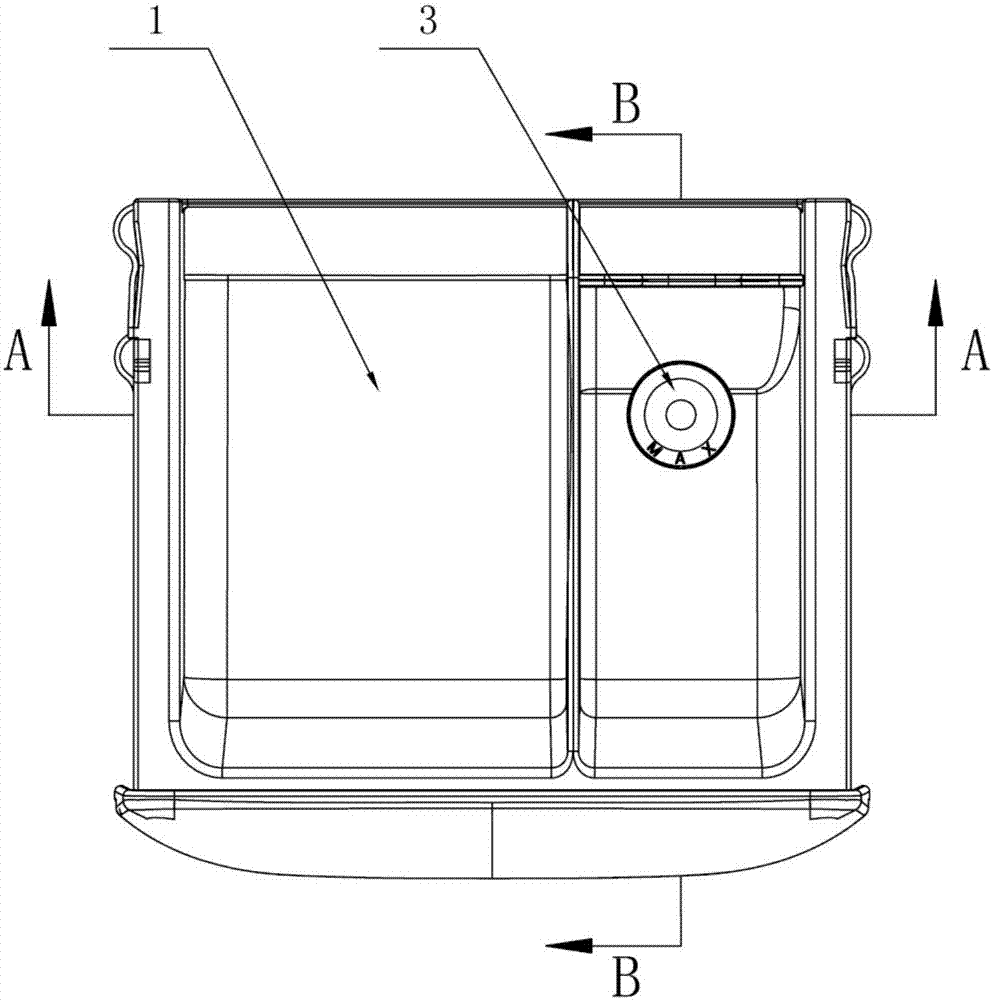

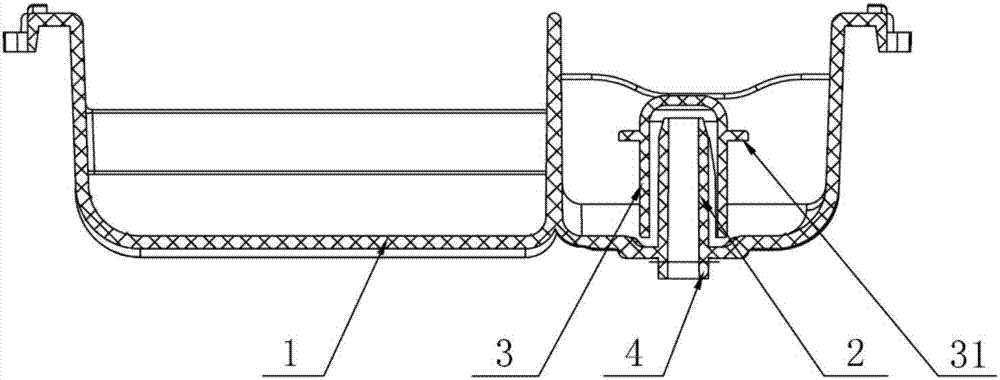

[0030] This embodiment provides a detergent box siphon structure, such as Figure 1-5 As shown, the siphon structure of the detergent box includes a siphon tube 2 and a siphon cap 3 arranged in the detergent box 1, wherein the siphon cap 3 is buckled on the siphon tube 2, specifically, the above-mentioned siphon tube 2 and the siphon cap 3 are arranged in the detergent box. The softener chamber and / or detergent chamber of the box 1 can be used to generate a siphon effect to absorb the softener or the mixture of laundry detergent and water (hereinafter collectively referred to as liquid) into the washing device.

[0031] In this embodiment, an annular rib 4 communicating with the siphon tube 2 is provided at the bottom of the detergent box 1 , and the above-mentioned siphon tube 2 , siphon cap 3 and annular rib 4 together constitute the detergent box siphon structure of this embodiment.

[0032] In this embodiment, the detergent box 1, the siphon tube 2 and the annular rib 4 ar...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that the location of the notch 5 in this embodiment is different. For details, please refer to Image 6 The notch 5 in the siphon structure of the detergent box in this embodiment is set at the position where the bottom of the detergent box 1 faces the lower surface of the siphon cap 3 . That is to say, a notch 5 is recessed at the position where the bottom of the detergent box 1 faces the lower surface of the siphon cap 3, so that the gap between the original siphon cap 3 and the bottom of the detergent box 1 is very small, forming One larger opening, in order to achieve the effect of weakening molecular force, make the negative pressure suction that the siphon tube 2 of detergent box 1 produces overcomes the object of molecular force more easily. Correspondingly, the siphon tube 2 in this embodiment does not have the notch 5 .

[0042] The rest of the structures are the same as those in Embodiment 1, and will...

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 is that the location of the notch 5 in this embodiment is different. For details, please refer to Figure 7In this embodiment, a first opening 11 is provided at the end of the siphon cap 3 near the bottom of the detergent box 1, and a second opening 31 is provided at the bottom of the detergent box 1 facing the first opening 11 (specifically The first opening 11 and the second opening 31 jointly form the notch 5 . In order to achieve the effect of weakening the molecular force, the negative pressure suction generated by the siphon 2 of the detergent box 1 can easily overcome the molecular force.

[0047] The rest of the structures are the same as those in Embodiment 1, and will not be repeated here.

[0048] The present invention also provides a detergent box 1, comprising the above-mentioned detergent box siphon structure.

[0049] The present invention also provides a washing device, including the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com