A method for detecting the abrasion resistance of yarn and its yarn winding friction device

A detection method and friction device technology, which is applied in the field of yarn wear resistance detection and yarn winding friction device, to achieve a simple and reliable detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific embodiment:

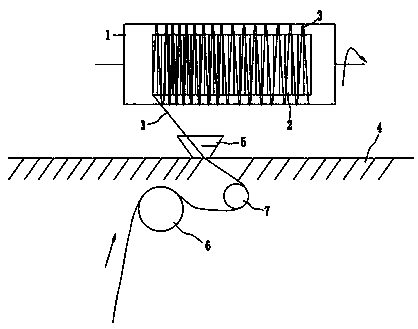

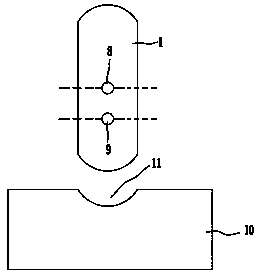

[0014] First of all, this embodiment provides a method for testing the wear resistance of yarns, which is to wind the yarn to be tested by using the turning plate in the upside-down state, so that the yarn to be tested is tightly wound on the end surface of the turning plate in turn, and the yarn to be tested After the yarn winding is completed, the overturning plate starts to overturn and the yarn on one end surface of the overturning plate is rubbed during the overturning process, and the yarn on the one end surface of the overturning plate is rubbed during each overturning process of the overturning plate. Hairiness detection and analysis. At the same time, yarn detection and analysis is carried out on the yarn that has not been rubbed on the other end surface of the turning plate, and the two are compared. Hairiness is performed on the yarn on the end surface of the turni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com