Double-shaft rolling type wear resistance testing device and method capable of simulating channel section form

A channel cross-section and testing device technology, which is applied to measuring devices, testing wear resistance, strength characteristics, etc., can solve problems such as low efficiency and unstable single-axis motor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The main defect of the prior art 1 whose patent publication number is CN110243710A is: the deviation of the experimental results caused by the vertical stirring of the motor; , but there are still the defects that it can only carry out the wear test under the single flow-solid condition, the fluid is easy to leak, and the instrument is easy to tilt. With the deepening of the research, it was found that there is a defect in the prior art that "the influence of the structural cross-section shape on the wear resistance properties in the process of the wear resistance test of concrete materials is ignored".

[0059] In view of the defects of the existing technology: first, the impact of the structural section shape on the wear resistance characteristics during the wear resistance test of the concrete material is ignored; second, the structure of the single-axis motor is unstable and the efficiency is low. This embodiment proposes a wear resistance test device different from...

Embodiment 2

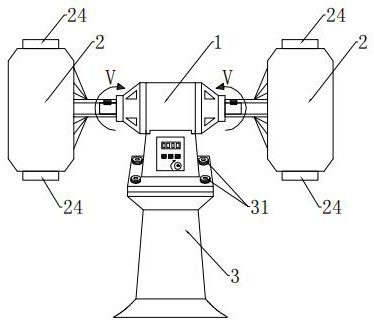

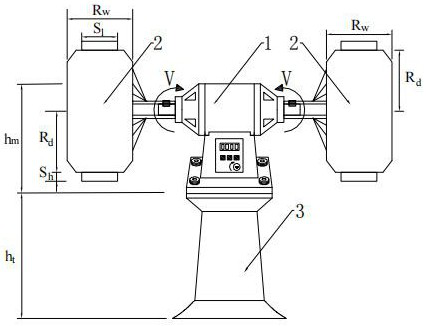

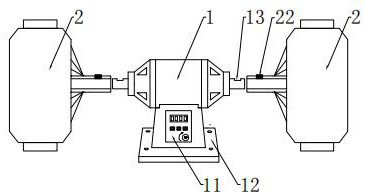

[0065] This embodiment is described in more detail on the basis of Embodiment 1. In this example, if figure 2 As shown, a double-axis roll-type wear resistance test device that can simulate the shape of the channel section includes a motor support base 3, a double-axis motor 1 installed on the motor support base 3, a series of detachable installations on the double-axis The disc device 2 on the spindle of the shaft motor 1 and a series of sample boxes 24 for placing samples.

[0066] Further, the biaxial motor 1 includes a motor body, a motor base 12 for installing the motor body, and a control panel 11 for controlling and displaying the working state of the motor body; the motor base 12 is installed on the motor support base 3 through base bolts 31 Above; the control panel 11 includes a built-in microcontroller, a speed display, a speed adjustment button, a start button, a stop button, and a timing device that are arranged on the work panel and connected to the microcontrol...

Embodiment 3

[0093] This embodiment is described in more detail on the basis of Embodiment 1 or Embodiment 2. This example discloses a test method for testing the wear resistance of concrete materials under different cross-sectional shapes and different flow velocities, using the double-axis roll-type wear-resistant testing device that can simulate the cross-sectional shape of the channel described in Example 1 to test the samples Carry out wear resistance test; the test method shown selects disc devices with different cross-sectional shapes 2, pours different types of concrete samples and configures different types of abrasive materials 6, according to the weight of the sample before abrasion, the weight of the sample after abrasion, and the sample Calculate the loss of sample mass over time and the depth change of sample mass over time, according to the loss of sample mass over time and the change of sample mass over time The depth change evaluates the abrasion resistance of the samples....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com