Glue joint surface efficient striking device for shoemaking glue joint and sole pressing

An adhesive bonding and high-efficiency technology is applied in the field of high-efficiency beating devices for adhesive bonding surfaces for shoe-making adhesive bonding and pressing soles, which can solve the problems of long beating time, easy fatigue of workers, and time-consuming and laborious beating of bonding surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

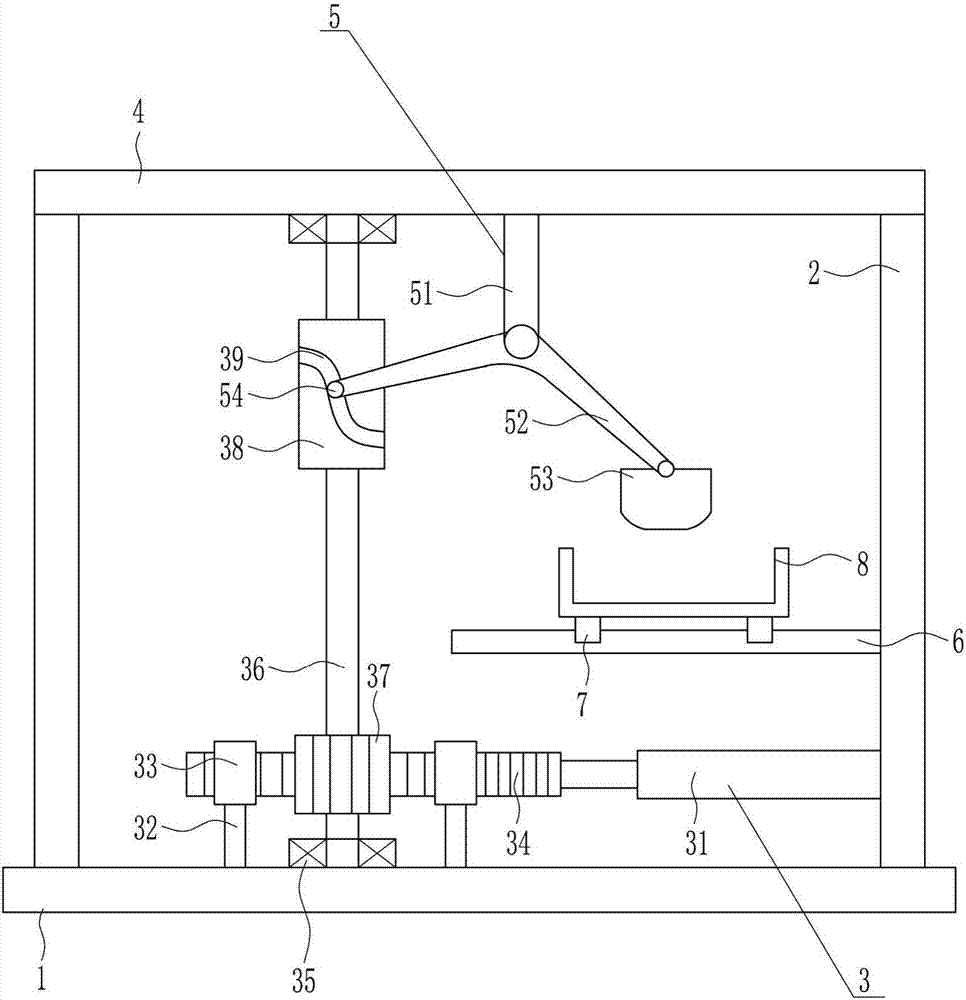

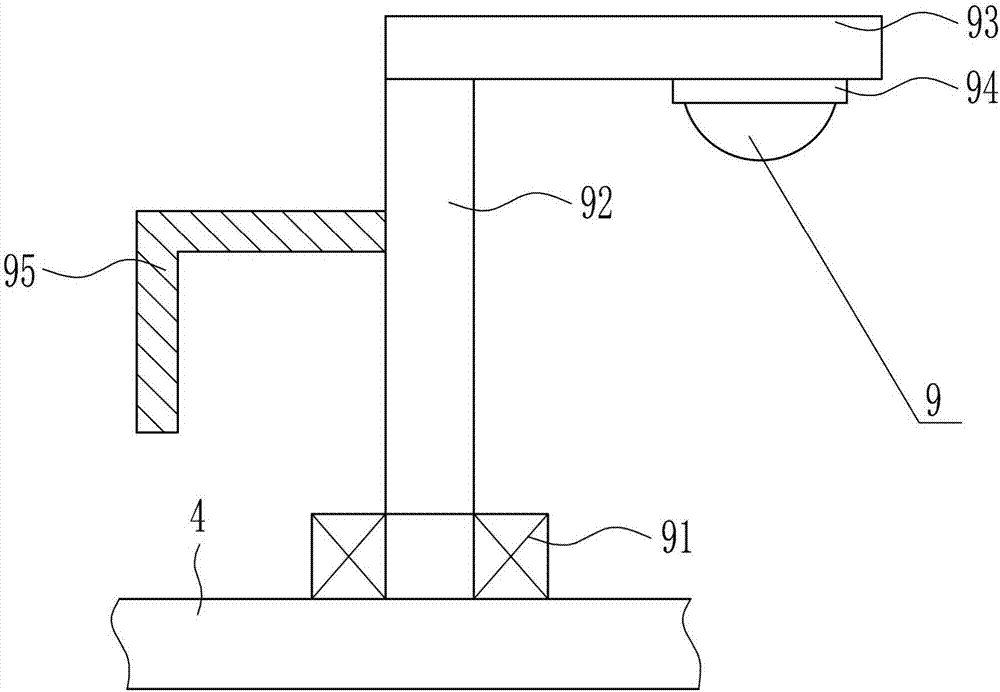

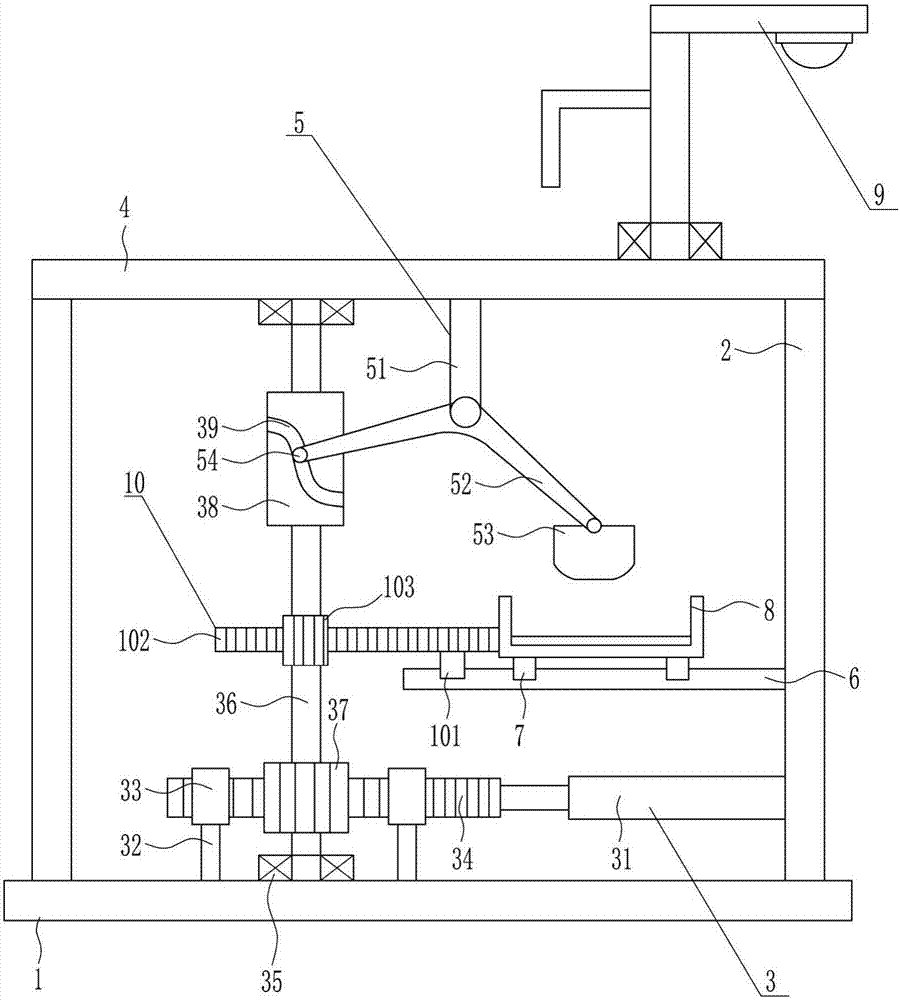

[0035] A high-efficiency beating device for glued joints used in shoemaking, such as Figure 1-6As shown, it includes a base plate 1, a bracket 2, a driving device 3, a top plate 4, a beating device 5, a first slide rail 6, a first slider 7 and a placement frame 8, and the top of the base plate 1 is symmetrically connected by bolts. Bracket 2, the bracket 2 is arranged vertically, the top of the two brackets 2 is connected horizontally with a top plate 4 by means of bolt connection, a driving device 3 is arranged between the two brackets 2, a knocking device 5 is installed in the middle of the bottom of the top plate 4, and the right side bracket 2 The middle part of the left side is horizontally installed with a first slide rail 6 by means of bolt connection, on which a first slide block 7 is slidably arranged, and the top of the first slide block 7 is connected with a placement frame by means of bolt connection 8. Place the frame 8 and the beating device 5 directly below the...

Embodiment 2

[0037] A high-efficiency beating device for glued joints used in shoemaking, such as Figure 1-6 As shown, it includes a base plate 1, a bracket 2, a driving device 3, a top plate 4, a beating device 5, a first slide rail 6, a first slider 7 and a placement frame 8, and the top of the base plate 1 is symmetrically connected by bolts. Bracket 2, the bracket 2 is arranged vertically, the top of the two brackets 2 is connected horizontally with a top plate 4 by means of bolt connection, a driving device 3 is arranged between the two brackets 2, a knocking device 5 is installed in the middle of the bottom of the top plate 4, and the right side bracket 2 The middle part of the left side is horizontally installed with a first slide rail 6 by means of bolt connection, on which a first slide block 7 is slidably arranged, and the top of the first slide block 7 is connected with a placement frame by means of bolt connection 8. Place the frame 8 and the beating device 5 directly below th...

Embodiment 3

[0040] A high-efficiency beating device for glued joints used in shoemaking, such as Figure 1-6 As shown, it includes a base plate 1, a bracket 2, a driving device 3, a top plate 4, a beating device 5, a first slide rail 6, a first slider 7 and a placement frame 8, and the top of the base plate 1 is symmetrically connected by bolts. Bracket 2, the bracket 2 is arranged vertically, the top of the two brackets 2 is connected horizontally with a top plate 4 by means of bolt connection, a driving device 3 is arranged between the two brackets 2, a knocking device 5 is installed in the middle of the bottom of the top plate 4, and the right side bracket 2 The middle part of the left side is horizontally installed with a first slide rail 6 by means of bolt connection, on which a first slide block 7 is slidably arranged, and the top of the first slide block 7 is connected with a placement frame by means of bolt connection 8. Place the frame 8 and the beating device 5 directly below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com