Apparatus and method for vertical and lateral fatigue test of longitudinal leaf spring

A technology of fatigue experiment and leaf spring, which is applied in the direction of measuring device, machine/structural component test, mechanical component test, etc., can solve the problems of fatigue experiment reliability and authenticity to be improved, no installation, etc., so as to improve reliability and authenticity, improved reliability, high authenticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

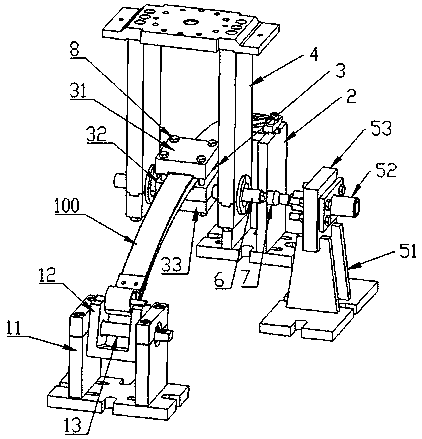

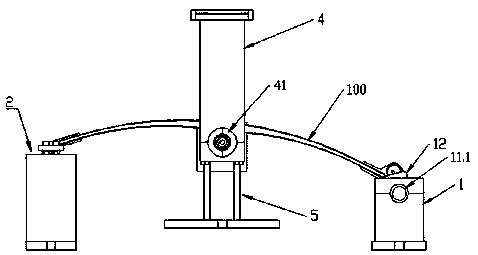

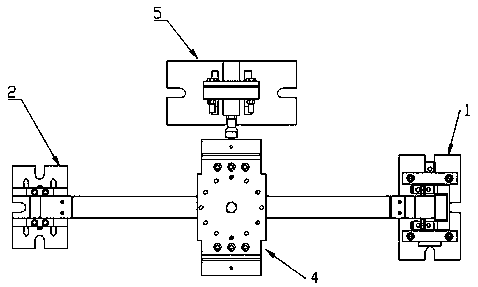

[0034] Combine below Figure 1 to Figure 4 Embodiments of the present invention are described in detail.

[0035] The longitudinal vertical fatigue test device of the plate spring includes the lifting lug bearing seat 1, the lifting lug fixing seat 2 aligned with the lifting lug bearing seat 1, and the middle clamping seat 3 clamped and fixed on the middle section of the leaf spring 100, along the vertical The vertical reinforcement frame 4 arranged in the direction and connected with the vertical loading device and the lateral reinforcement seat 5 arranged in the side direction and connected with the lateral loading device are characterized in that one end of the leaf spring 100 is arranged in the longitudinal direction. It is swingably mounted on the lifting lug bearing seat 1, and the other end of the lifting lug is fixed on the lifting lug fixing seat 2. The vertical reinforcement frame 4 is in the shape of a door frame, and straddles the middle clamping seat 3 in the late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com