Tool assembly

A technology of knives and tool holders, applied in the direction of manufacturing tools, stone processing tools, work accessories, etc., can solve the problems of low cutting efficiency, achieve the effects of improving work efficiency, preventing slippage, and strengthening relative fixing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

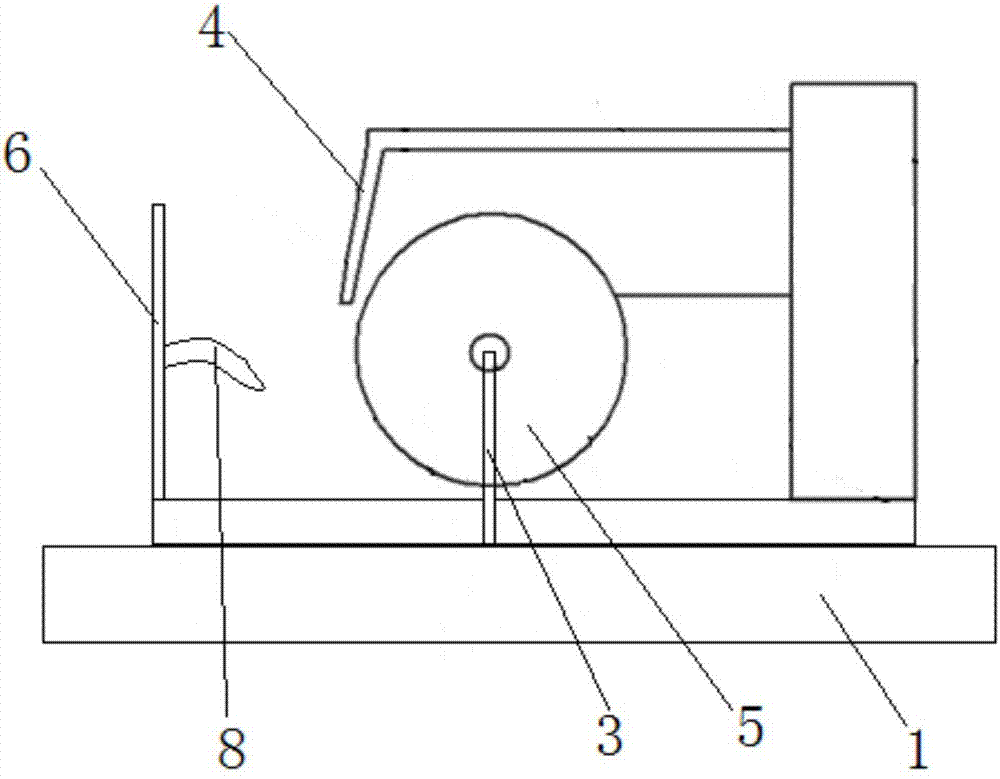

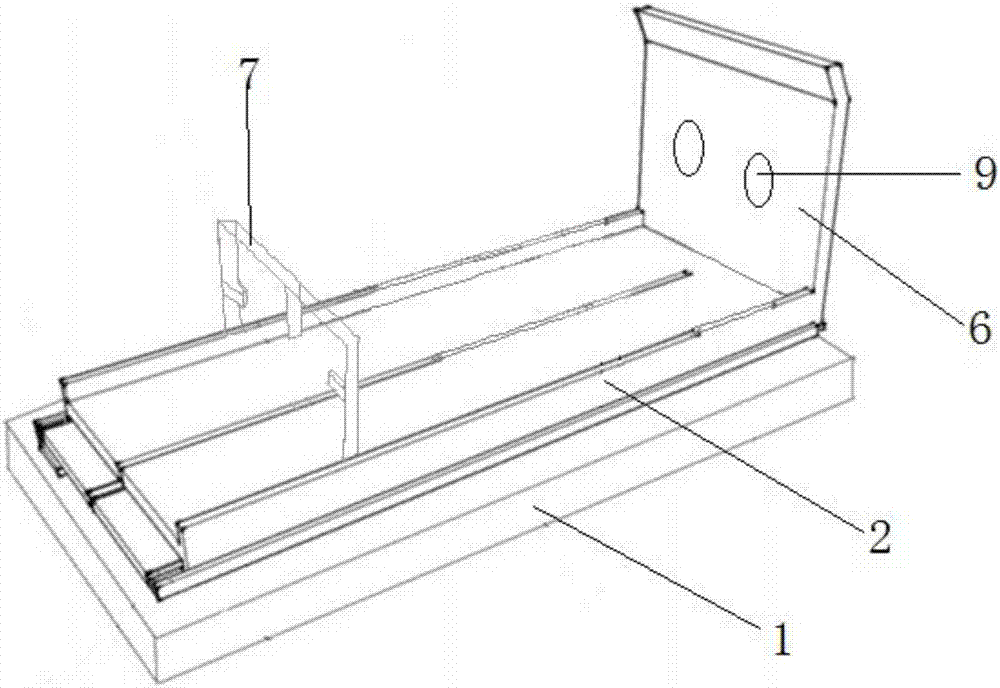

[0015] like figure 1 , 2 As shown, the cutter 5 combination in the present invention includes a base 1, a slide plate 2 connected to the base 1 by slide rails, a cutter 5 frame 3 erected on the base 1, and water nozzles 4 placed on both sides of the cutter 5, rock The cutting process produces a large amount of heat, which is easy to damage the blade. The water flow nozzle 4 is placed on the side of the cutter 5 blade, and the sprayed water flows into the blade to cool down. Cutter 5 frame 3 comprises a rotating shaft across slide plate 2, and rotating shaft is parallel to sliding plate 2, and the rotating shaft is provided with a plurality of draw-in slots for connecting cutter 5, and cutter 5 is connected on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com