Function test method for pressure accumulating block assembly of low-speed machine for ME-B type ship

A test method and low-speed machine technology, applied in fluid pressure actuation system testing, mechanical equipment, fluid pressure actuation devices, etc., can solve problems such as no verification method for the function of the pressure accumulator block assembly, and achieve quality assurance and efficient diagnosis The effect of the method

Inactive Publication Date: 2017-11-24

CHONGQING HONGJIANG MACHINERY

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is currently no professional, specific and comprehensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

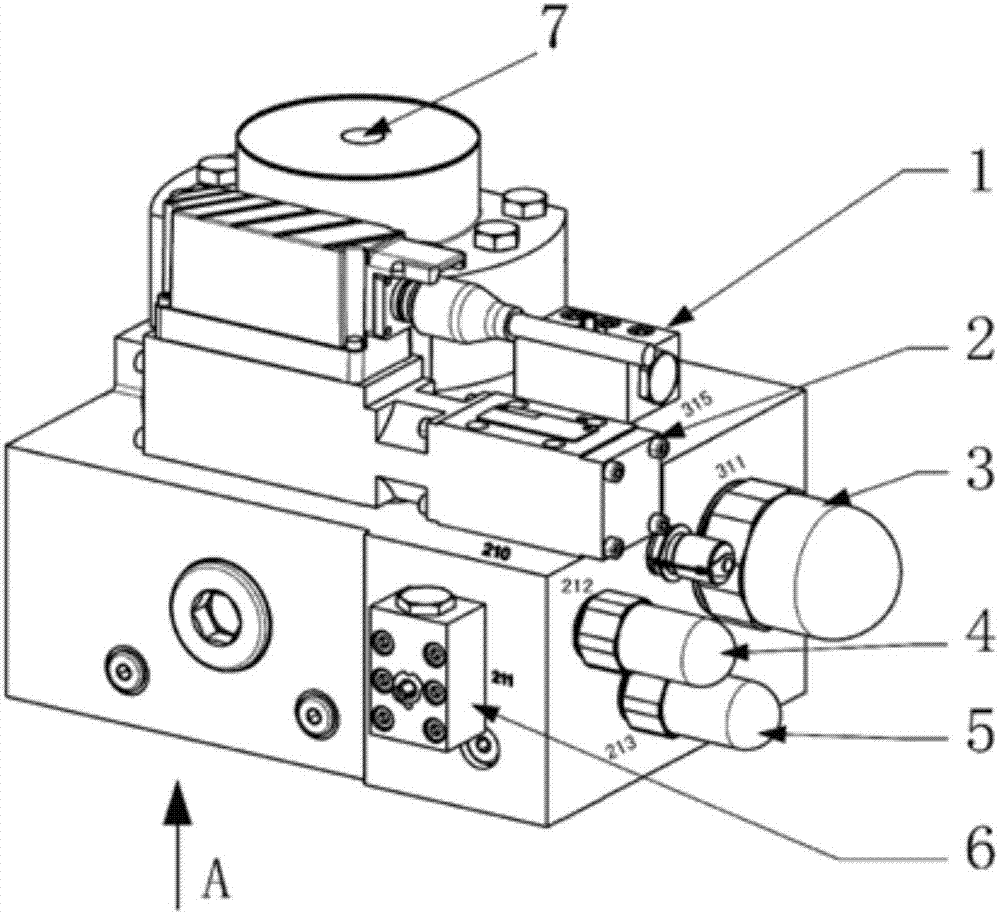

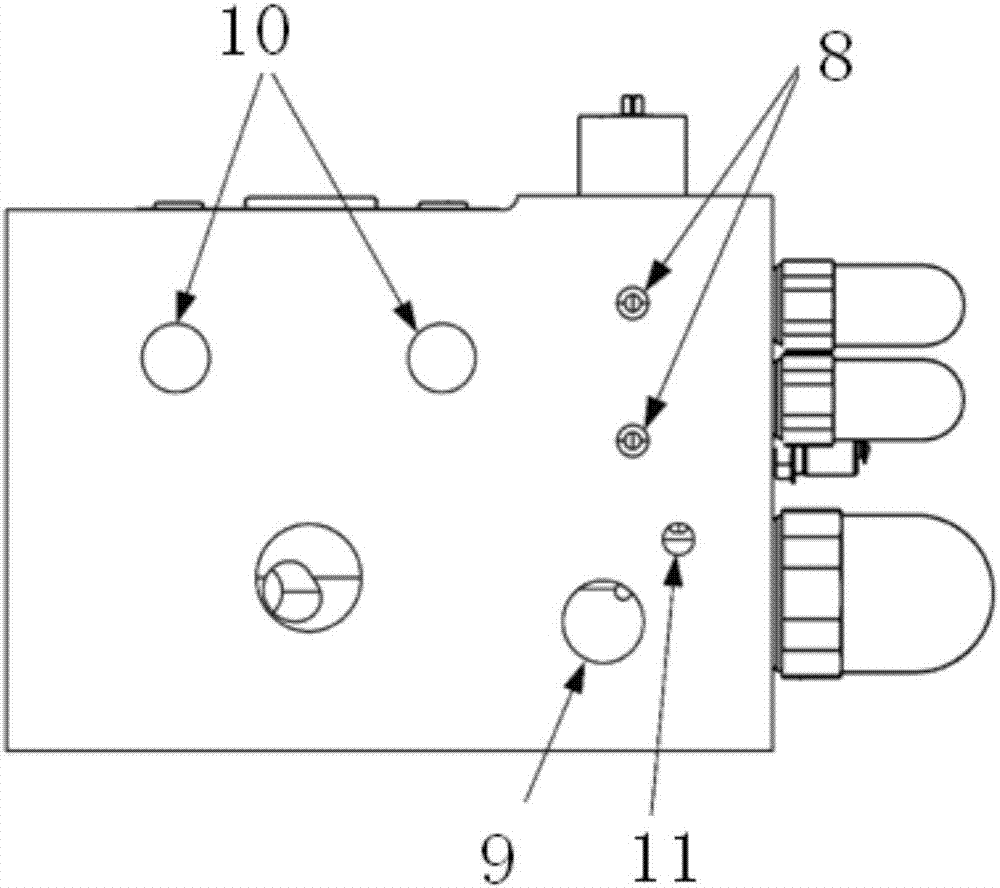

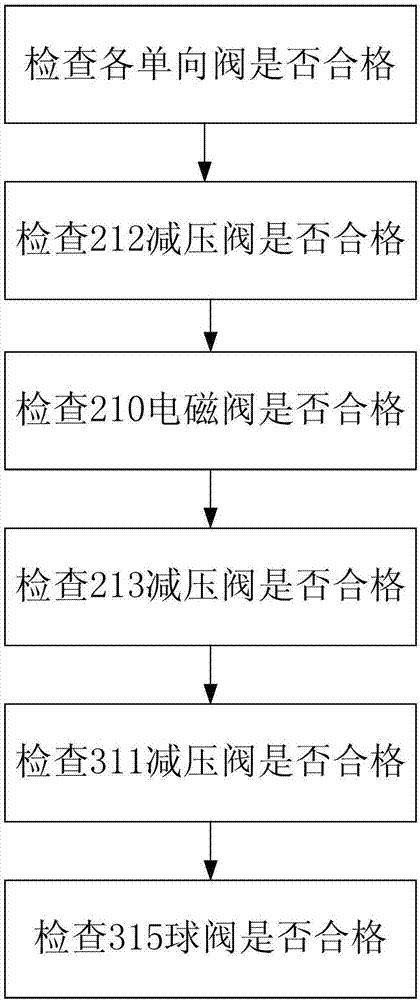

The invention discloses a function test method for a pressure accumulating block assembly of a low-speed machine for an ME-B type ship. The function test method comprises the following steps: testing each one-way valve, a 212-pressure reducing valve, a 210-electromgantic valve, a 213-pressure reducing valve, a 311-pressure reducing valve and a 315-ball valve on the pressure accumulating block assembly in sequence; and judging the functional validity of the pressure accumulating block assembly according to different test expressions. The pressure accumulating block assembly is ensured to work normally in subsequent use through the test, or a fault point is diagnosed through the test when the pressure accumulating block assembly is maintained. According to the pressure accumulating block assembly function test method for the low-speed machine for the ME-B type ship, the functions of the pressure accumulating block assembly of the low-speed machine for the ME-B type ship can be verified comprehensively and accurately; a failure point can be found out and repaired timely; the quality of a product is ensured; and a high-efficiency diagnosis method is also provided for after-sale maintenance.

Description

technical field [0001] The invention belongs to the field of ME-B type marine low-speed engine, and in particular relates to a test method for a pressure accumulator block assembly in a hydraulic power supply system of the low-speed engine. technical background [0002] In the ME-B marine low-speed engine, many systems such as the fuel supply system and the lubricating oil system adopt the hydraulic power mode, and the main function of the pressure accumulator block assembly in the low-speed engine is to transfer the hydraulic oil pressurized by the hydraulic pump station. Stable delivery to each system. If the accumulator block assembly fails during use, it will affect the operation of the entire low-speed machine. Therefore, the ability to check the performance of the pressure accumulator block assembly before installation and use will help reduce the possibility of malfunctions in use. In addition, if the fault point can be found in time after a fault occurs, the mainte...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F15B19/00

CPCF15B19/005

Inventor 张重李野陈明周科汪波

Owner CHONGQING HONGJIANG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com