Airspace engine protective cover

A technology of protective cover and engine, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of missing fasteners, damage to spacecraft equipment, falling, etc., so as to solve the problem of missing or falling fasteners, The effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

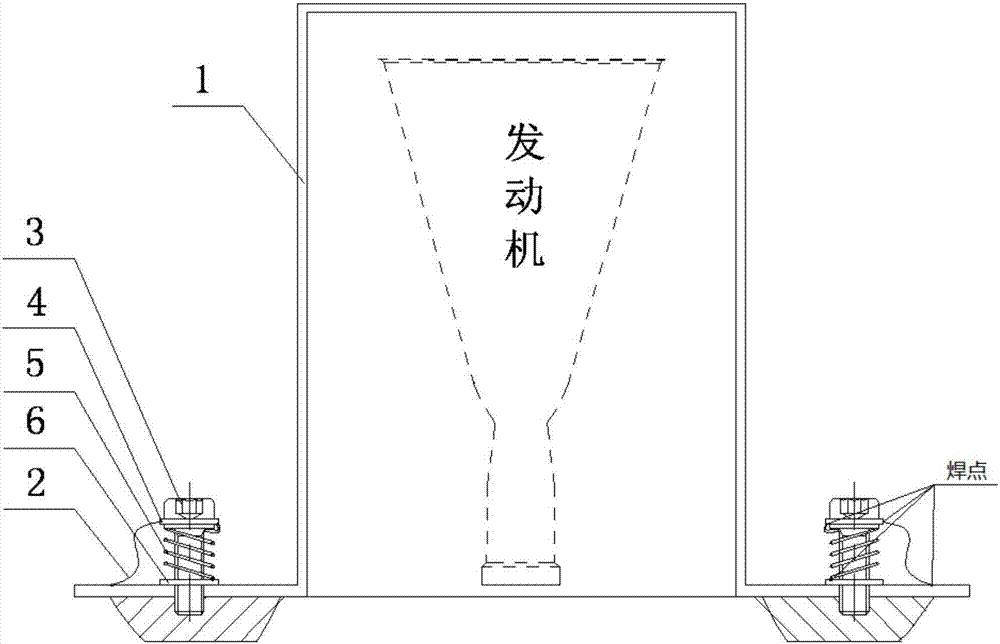

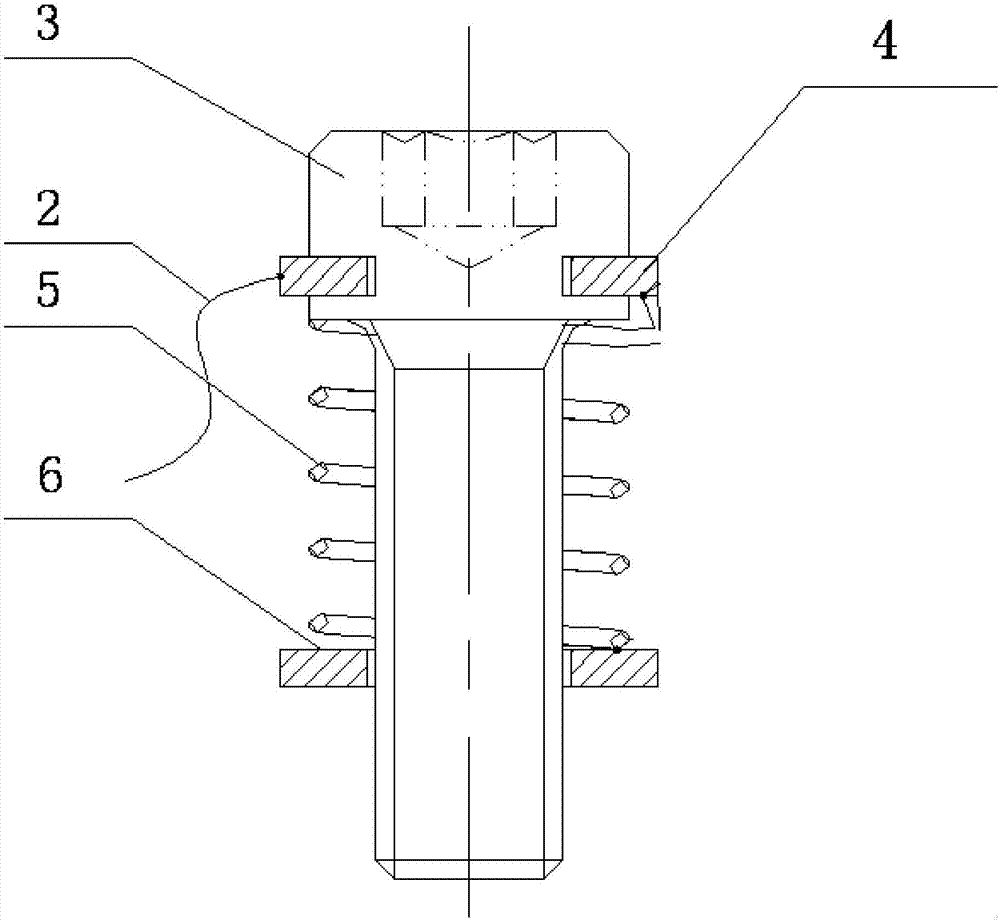

[0015] Such as figure 1 As shown, the embodiment of the present invention provides a spacecraft engine protective cover, including a protective cover body 1, and the ear pieces of the protective cover body 1 are movably connected with hexagon socket head cap screws 3, such as figure 2 As shown, a shaft circlip 4, a spring 5 and a flat washer 6 are sequentially arranged between the hexagon socket head cap screw 3 and the lug from top to bottom, and the upper end of the spring 5 is connected to the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap