Temperature compensation of a signal in a vibratory meter

A temperature compensation and measuring instrument technology, applied in volume measurement, volume change compensation/correction device, instrument, etc., can solve problems such as change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

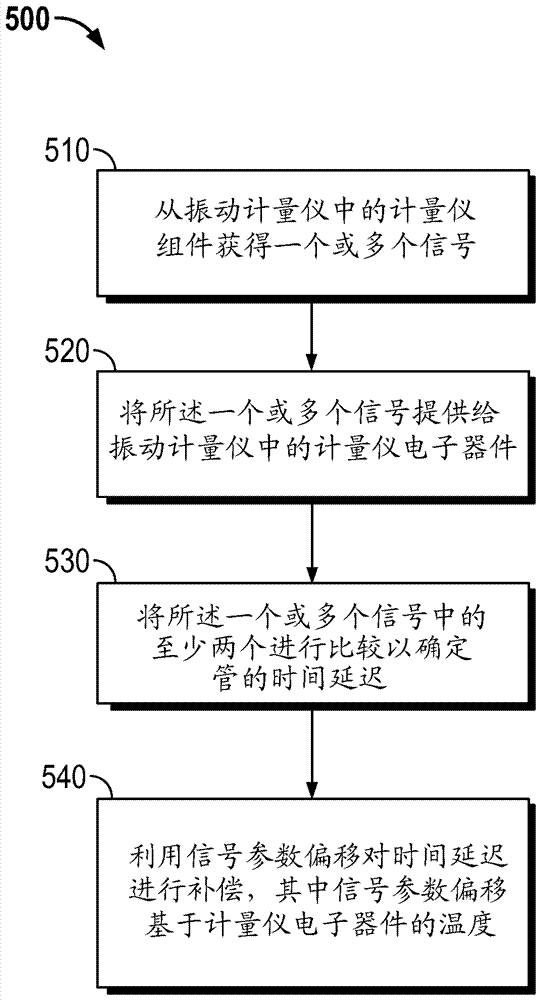

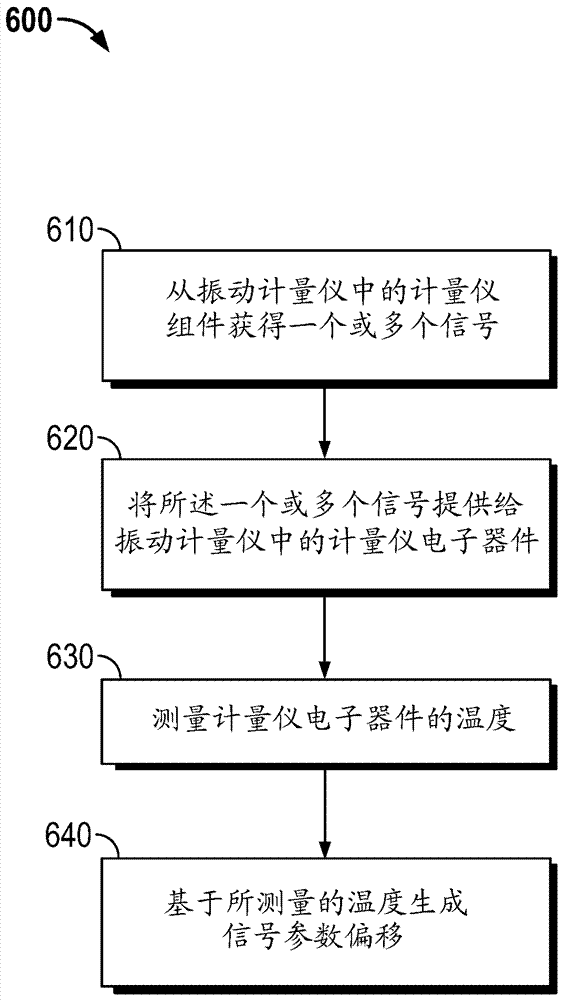

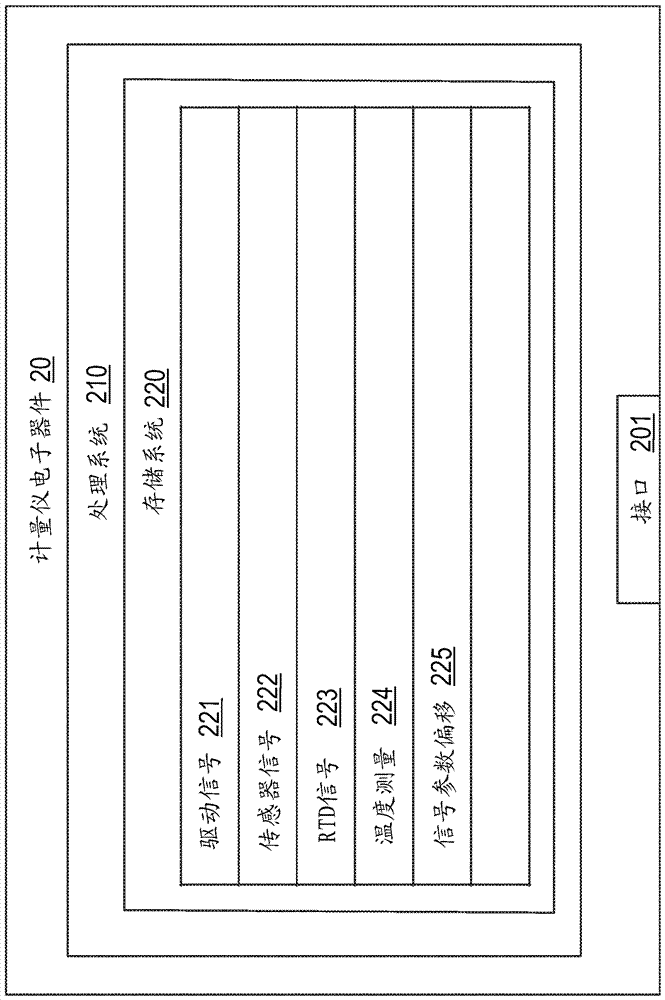

[0038] Figure 1-Figure 6 and the following description depict specific examples to teach those skilled in the art how to make and use the best mode of embodiment for temperature compensation of signals in a vibrating meter. For the purpose of teaching the innovative principles, some conventional aspects have been simplified or omitted. Those skilled in the art will appreciate variations from these examples that fall within the scope of the description. Those skilled in the art will appreciate that the features described below can be combined in various ways to form numerous variations of temperature compensation of signals in vibrating meters. As a result, the embodiments described below are not limited to the specific examples described below, but only by the claims and their equivalents.

[0039] figure 1Vibration meter 5 is shown including meter assembly 10 and meter electronics 20 . The meter assembly 10 is responsive to the mass flow rate and density of the process m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com