Electric power archive management device

A file management and power technology, applied in home appliances, applications, shelves, etc., can solve problems such as troublesome file search, and achieve the effect of convenient access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

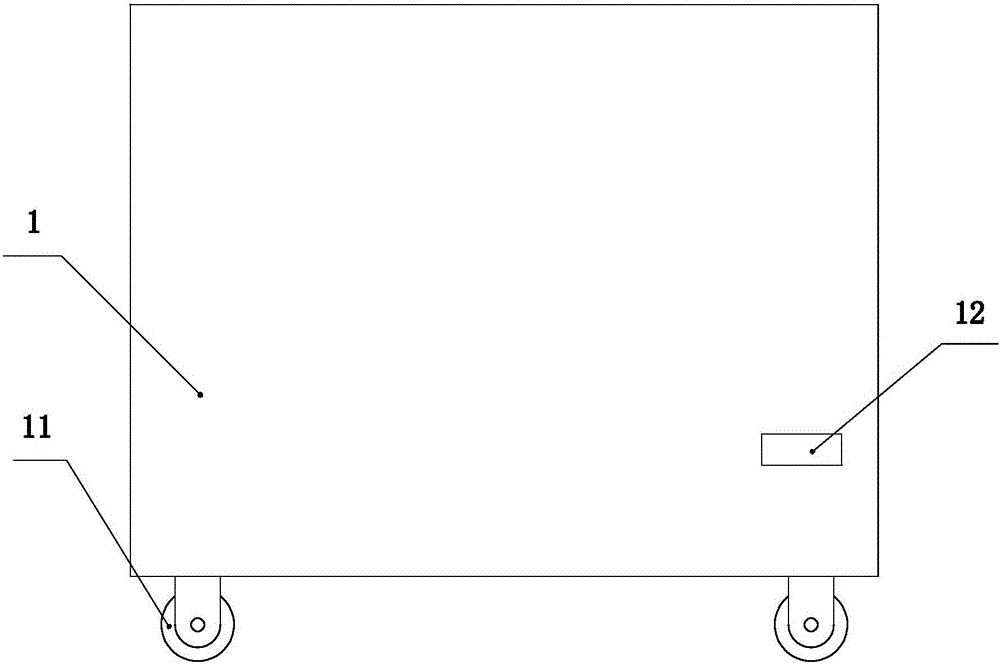

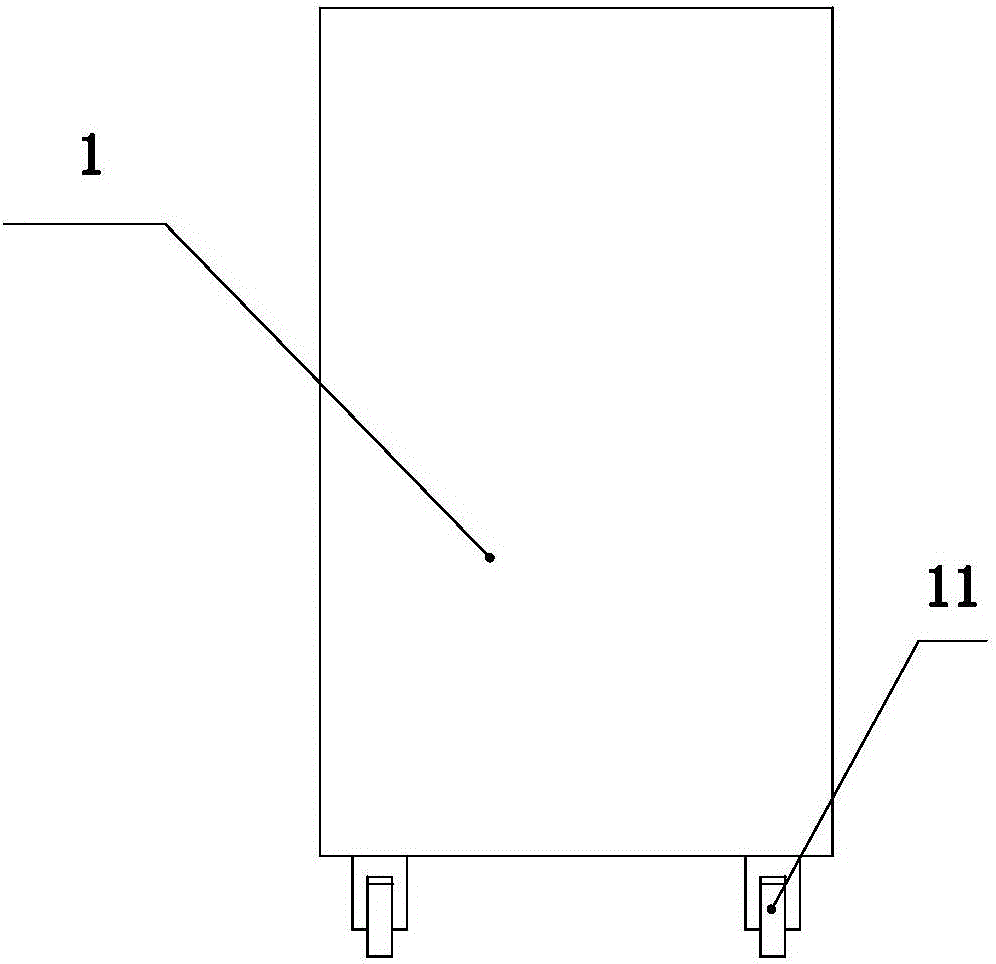

[0030] Such as figure 1 , figure 2 As shown, the cabinet body 1 is a substrate of the present invention, and a traveling wheel 11 is provided at the bottom of the cabinet body. An outlet 12 is provided on the front side wall of the cabinet, and the file box with files is pushed out from the outlet.

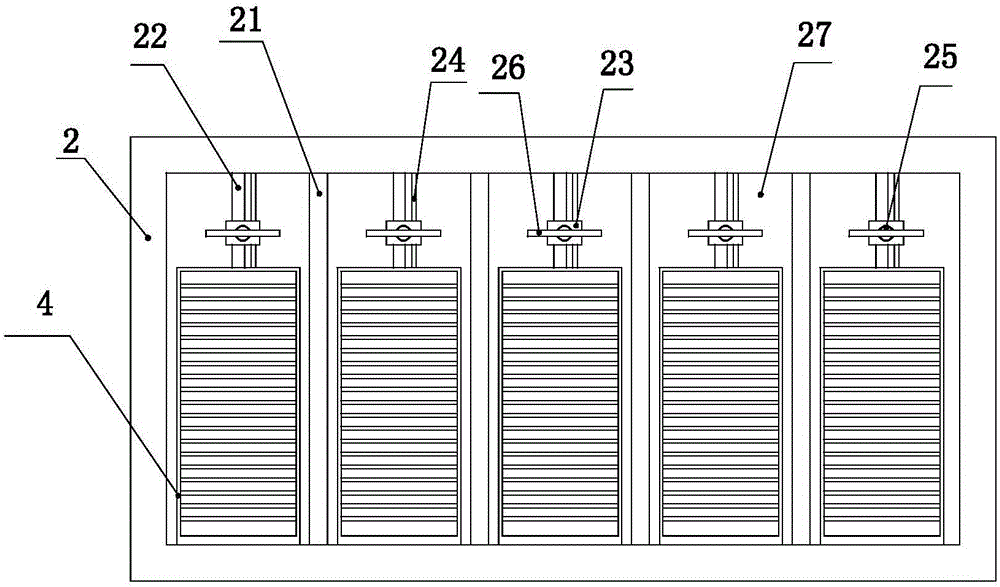

[0031] There is a frame 2 inside the cabinet, such as image 3 As shown, the frame is a cuboid-shaped hollow structure with an open front end, and several vertically placed vertical boards 21 are arranged on the inner side of the frame, and the vertical boards are arranged at equal intervals. The riser divides the inner chamber of the frame into several chambers 27, such as Figure 5 As shown, the rear side of each chamber is provided with a vertical first lead screw 22, the two ends of the first lead screw are fixed in the inner ring of the bearing 28, and the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com