Fixed-point self-locking mechanism

A self-locking and block-tightening technology, applied in mechanical equipment, fixtures, etc., can solve the problems of reducing the degree of automation of products, difficult to maintain accuracy, and inability to insert pins, so as to ensure positioning accuracy and repeat positioning accuracy. The effect of long-term positioning accuracy maintenance and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

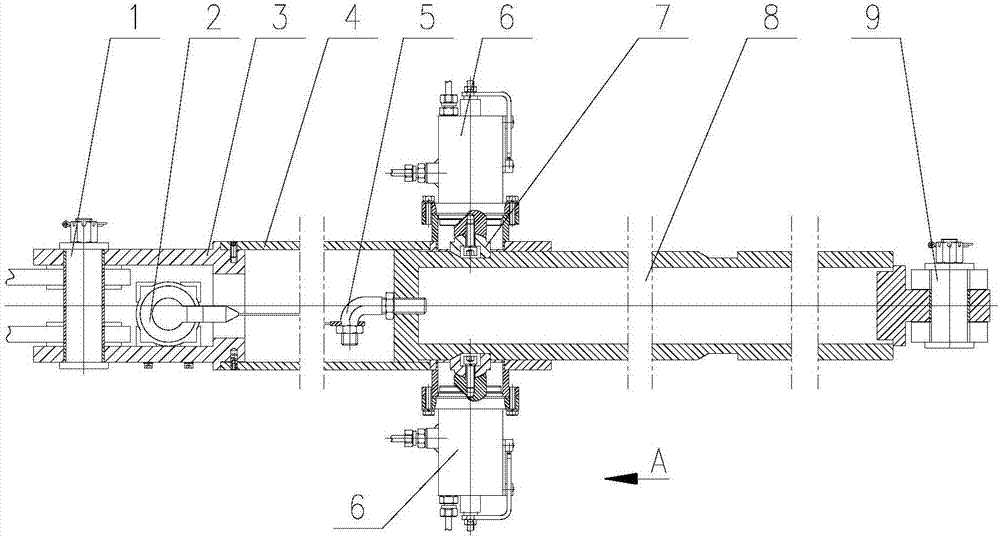

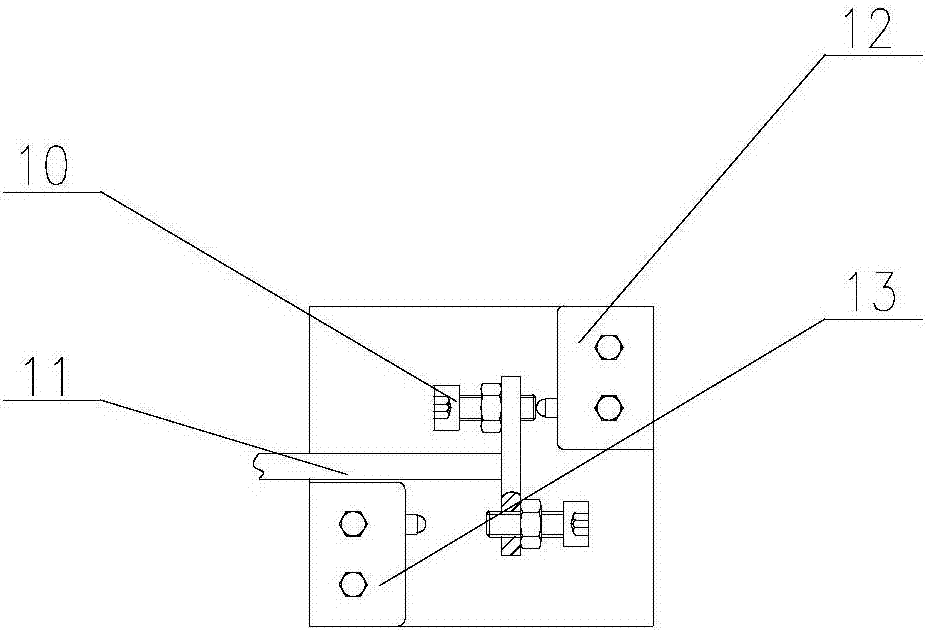

[0025] Such as figure 1 , figure 2 A fixed-point self-locking mechanism shown includes an outer cylinder flange 3, an outer cylinder 4, a rope puller (5), a locking cylinder 6, a universal locking block 7, and an inner cylinder 8; the outer cylinder flange 3 and the end of the outer cylinder 4 are connected and fixed, and the outer cylinder 4 is covered with an inner cylinder 8; a locking cylinder 6 is fixed on the outer cylinder 4, and the inner end of the locking cylinder 6 is connected with a universal locking block 7, and the locking cylinder 6 A trigger 10 and a sensor 11 are arranged on the top, and the start and stop of the locking cylinder 6 can be controlled by the trigger 10 and the sensor 11; the inner cylinder 8 is provided with an annular slot, and the shape of the annular slot matches the universal locking block 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com