A lead-acid battery battery tank

A technology of lead-acid batteries and battery tanks, applied in the direction of lead-acid batteries, lead-acid battery construction, battery pack components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below.

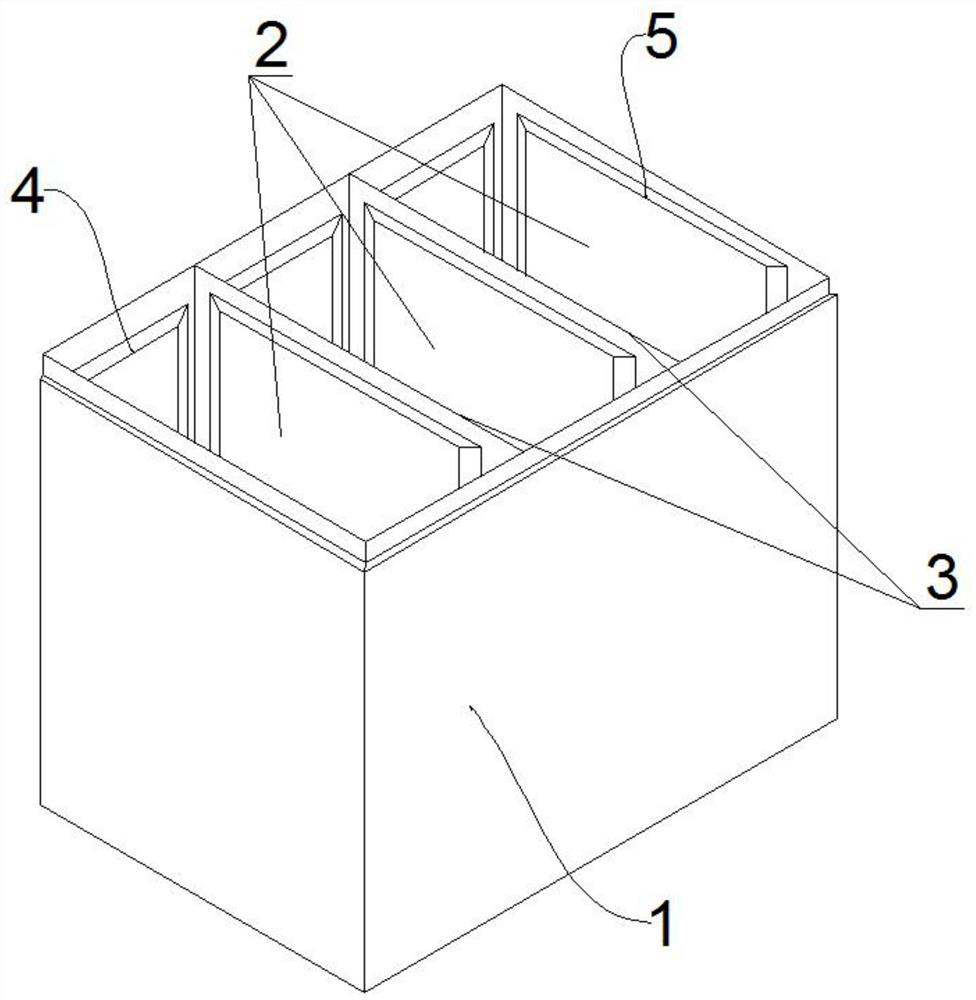

[0017] Such as Figure 1 to Figure 3 As shown, a battery tank for a lead-acid battery includes a battery tank 1, inside the battery tank 1 there are evenly arranged a plurality of separators 3 parallel to the left side plate and the right side plate along the left and right directions, and the plurality of separators The plate 3 divides the internal space of the battery tank 1 into several cell chambers 2, each cell chamber 2 is provided with an elastic support member-4 on the front side wall and the rear side wall, and the left side of each cell chamber 2 An elastic support member 25 is arranged on the side wall and the right side wall;

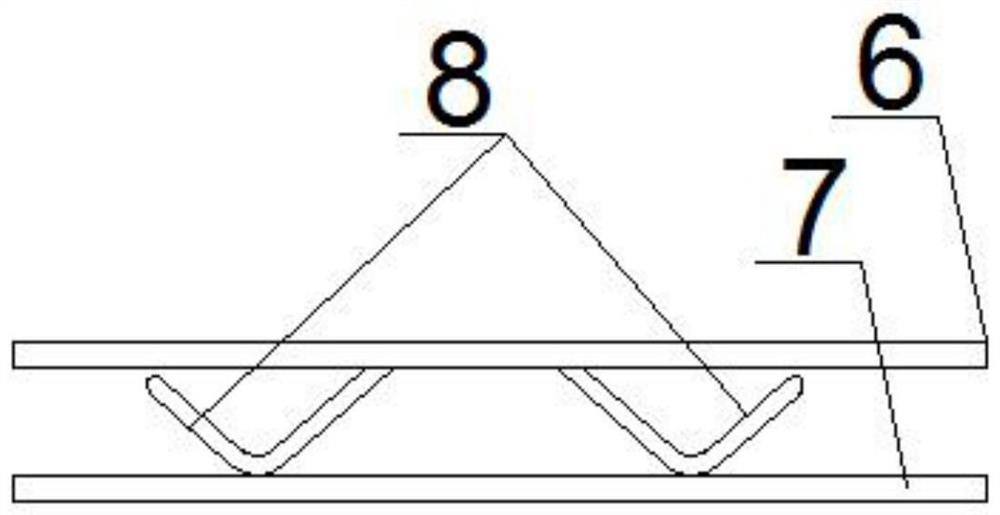

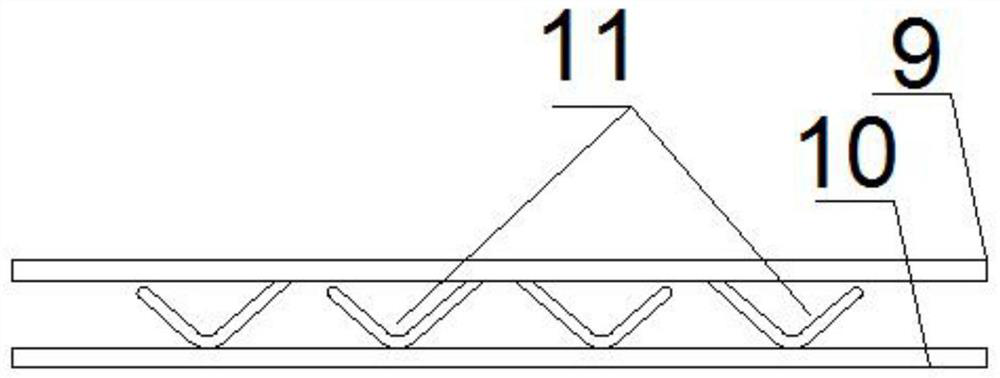

[0018] The elastic supporting member 4 consists of a support plate 6 and a pressure plate 7 with the same shape and size, and two vertically extending V-shaped shrapnel evenly arranged between the support plate 6 and the pressure plate 7 One 8 is composed of, the V-shaped elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com