Cable fixing comb and manufacturing method thereof

A technology for fixing combs and arranging wires, which is applied in the direction of busbar/line layout, substation/switch layout details, electrical components, etc., and can solve problems such as not being able to achieve the best fixed position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

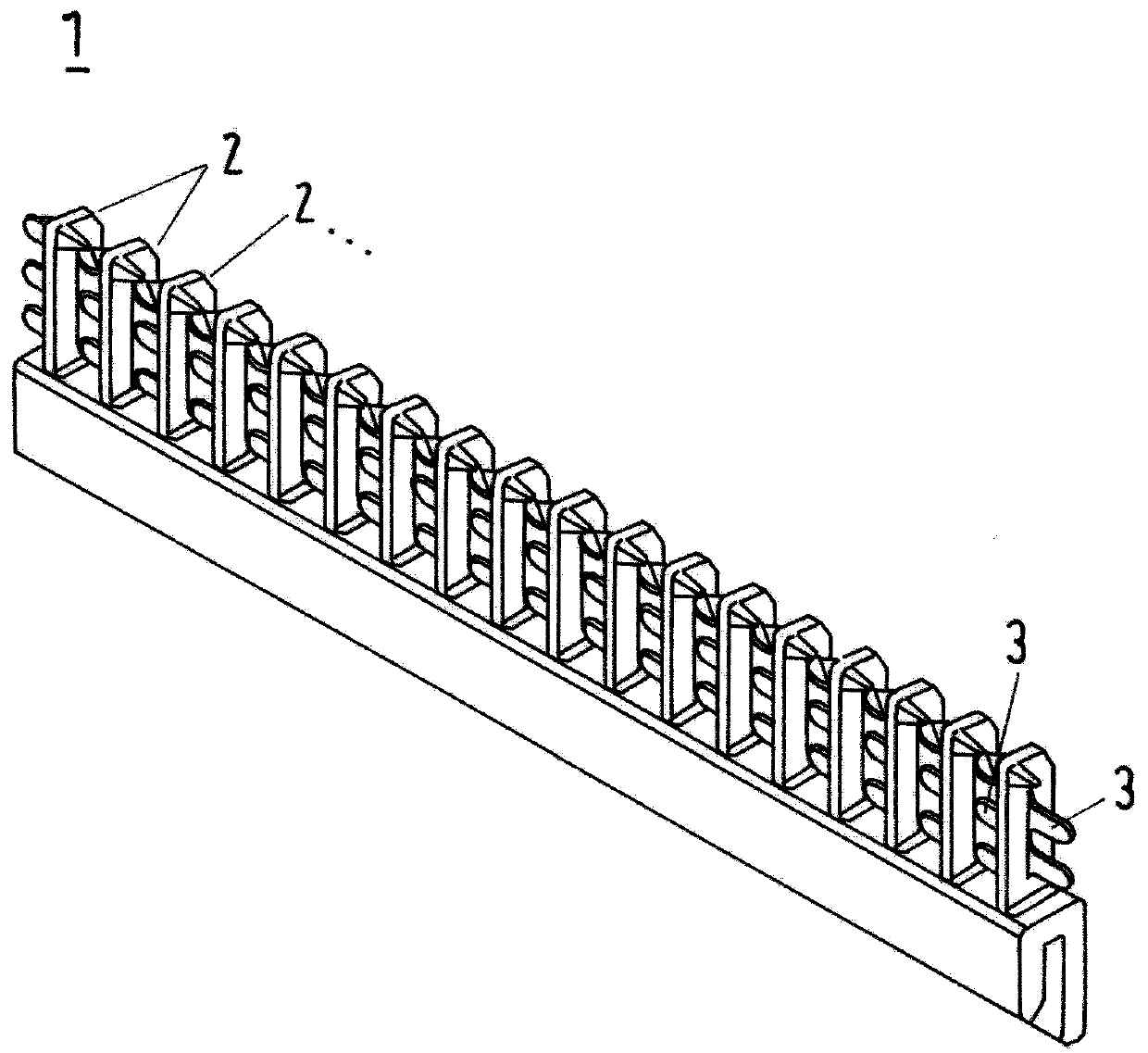

[0017] figure 1 Shown is a routing comb 1 with teeth 2 arranged in parallel. A slit flag 3 is positioned between the teeth. The wire will be inserted between the teeth and pushed towards the socket 4 from above. With this action, the slit flag will be deployed. After the wire reaches its final position between the teeth, the portion of the slit flag above the wire will bend back and secure the final position of the wire.

[0018] figure 2 shown from the rear figure 1 Cable 1 shown.

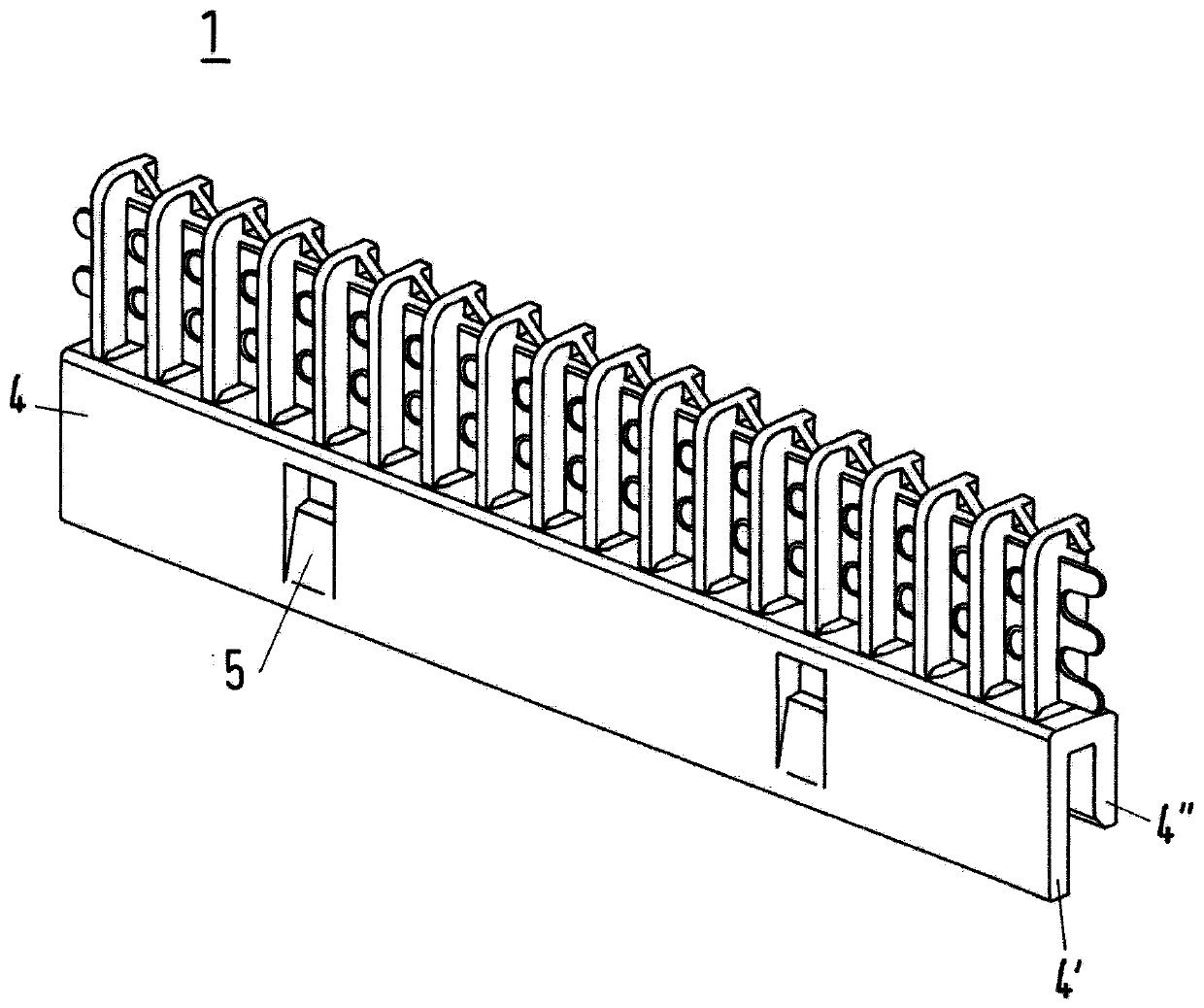

[0019] The socket 4 has a cross-section of a U-profile in the form that one side 4' of the socket is longer than the other side 4" of the socket.

[0020] Furthermore, in the longer side 4' of the socket 4, a snap element 5 is arranged integrally therein.

[0021] By means of these snap-in elements 5, the cable fixing comb 1 can be fixed on a support plate, for example in a low-voltage chamber.

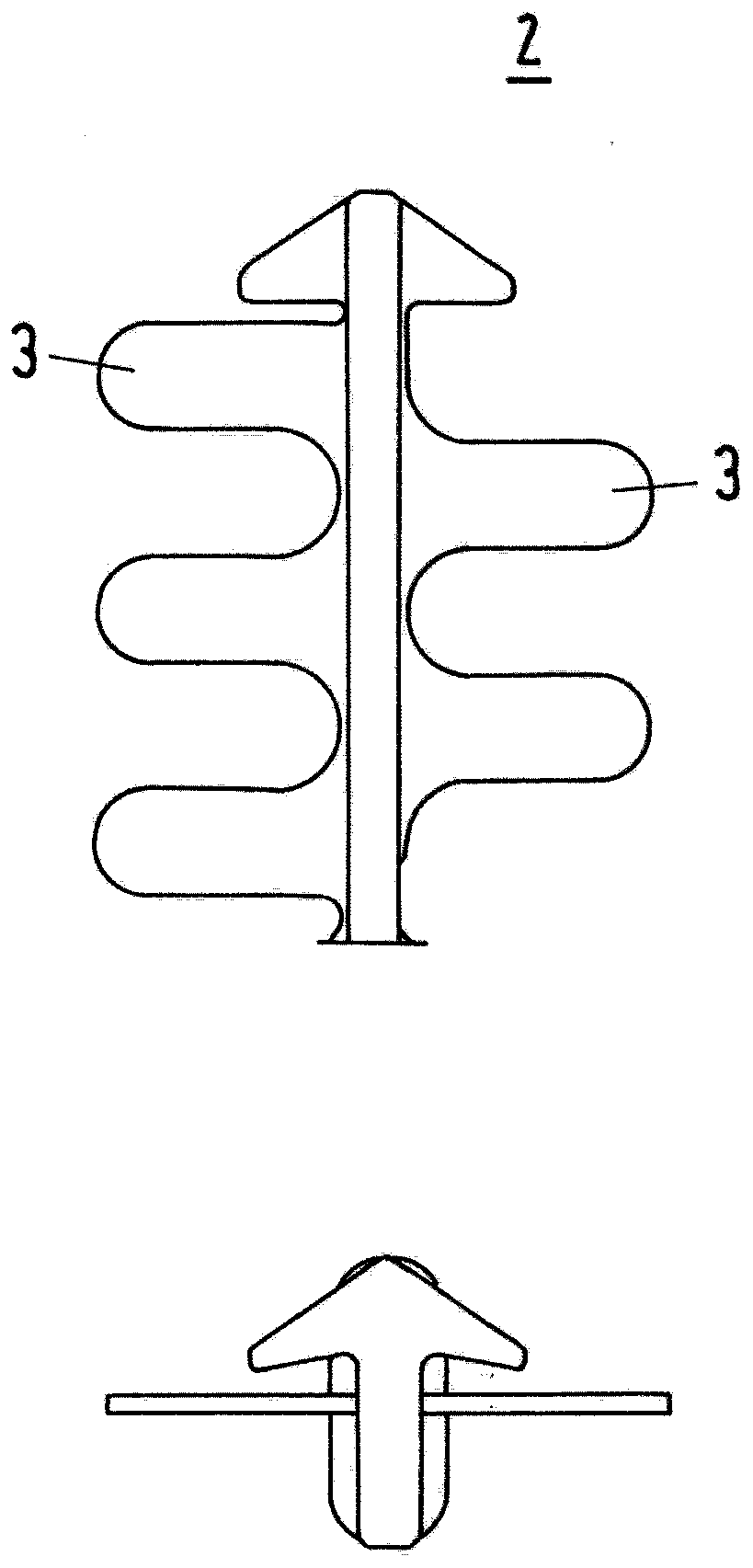

[0022] image 3 A detailed view of a single tooth 2 of the wire fixing comb 1 is shown. It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com