Tool and method for testing adhesive property of frameless self-adhesive enameled wire

A technology for testing tooling and testing methods, which is applied in the field of enameled wire coils, can solve problems such as long testing time, low work efficiency, easy deformation, etc., and achieve the effect of efficient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

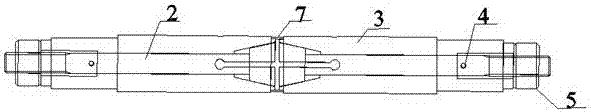

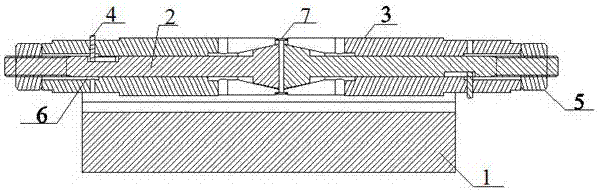

[0025] As a preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , this example discloses:

[0026] A tooling for testing the bonding force of skeletonless self-adhesive enameled wire, including a base 1, two sets of tooling fixtures and a skeletonless self-adhesive enameled wire coil 7; the two sets of tooling fixtures are symmetrically arranged on the base 1, and the skeletonless self-adhesive enameled wire coil 7 One end of one end is connected on a set of tooling fixtures, and the other end is connected on another set of tooling fixtures; the tooling fixtures include tension screws 2, expansion sleeves 3, lock nuts 5 and positioning pins 4; the expansion sleeves 3 is socketed on the tightening screw 2, and the expansion nut is threadedly connected to the threaded end of the tightening screw 2, the limiting groove 6 is arranged on the tightening screw 2, and the expansion sleeve 3 is provided with a positioning hole and a positioning...

Embodiment 2

[0028] As another preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , this example discloses:

[0029] A tooling for testing the bonding force of skeletonless self-adhesive enameled wire, including a base 1, two sets of tooling fixtures and a skeletonless self-adhesive enameled wire coil 7; the two sets of tooling fixtures are symmetrically arranged on the base 1, and the skeletonless self-adhesive enameled wire coil 7 One end is connected to a set of tooling fixtures, and the other end is connected to another set of tooling fixtures; the tooling fixtures include tension screws 2, expansion sleeves 3, locking nuts 5 and positioning pins 4; the locking sleeves 3 is socketed on the tightening screw 2, and the expansion nut is threadedly connected to the threaded end of the tightening screw 2, the limiting groove 6 is arranged on the tightening screw 2, and the expansion sleeve 3 is provided with a positioning hole and a positioning pin...

Embodiment 3

[0031] As another preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , this example discloses:

[0032] A method for testing the bond strength of skeletonless self-adhesive enameled wire, comprising the following steps:

[0033] Step A, preparing the skeletonless self-adhesive enameled wire coil 7, the self-adhesive enameled wire is wound on the skeleton and thermally bonded to form a skeleton coil to be tested, and the skeletonless self-adhesive enameled wire coil 7 is formed after demolding;

[0034]Step B, prepare the tooling fixture, install the tensioning screw 2 in the expansion sleeve 3, press the positioning pin 4 on the expansion sleeve 3, and insert the positioning pin 4 into the expansion sleeve 3 at the end of the tensioning screw 2 In the limit groove 6, install the lock nut 5 on the threaded end of the tension screw 2, and turn the lock nut 5 to make the tension screw 2 move in the expansion sleeve 3; assemble two sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com