Bottle and can rack

A technology of can racks and bottles and cans, which is applied in the cabinets for storing bottles, household appliances, applications, etc., can solve the problems of invisible, difficult to store tall and thin bottles and cans, and inconvenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

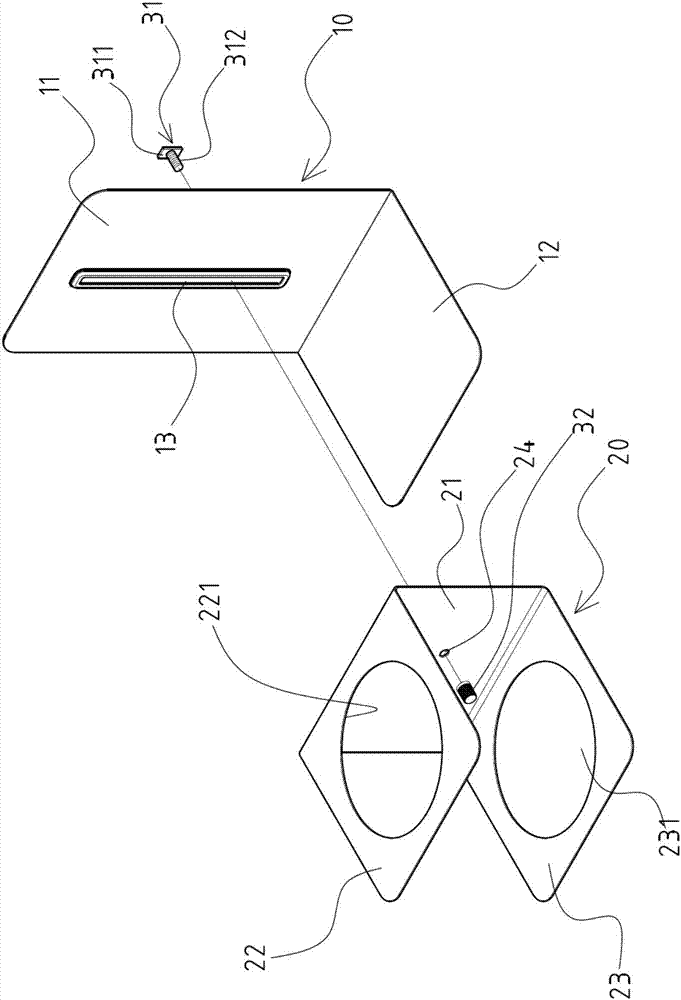

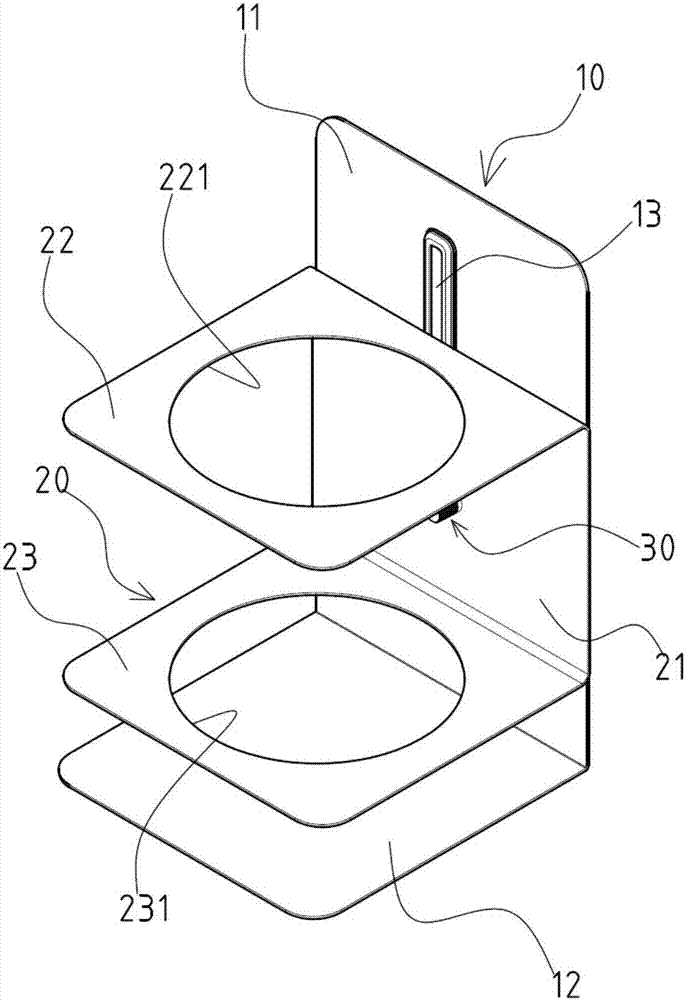

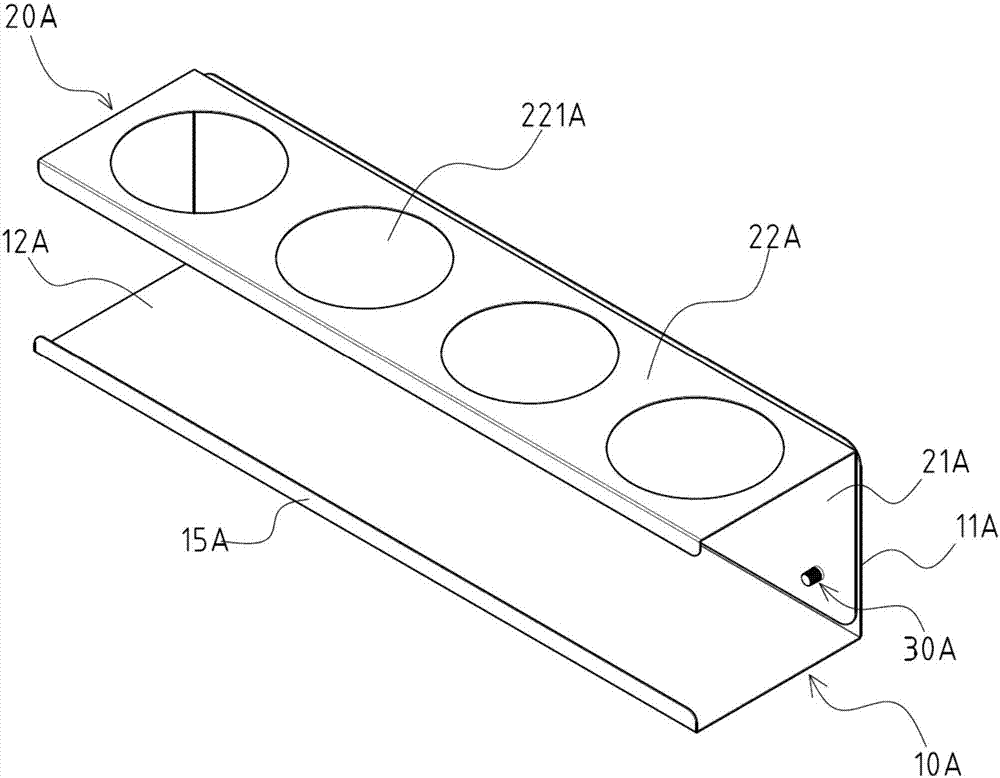

[0018] Such as figure 1 , 1A , 8, the first preferred embodiment of the bottle rack of the present invention, but these embodiments are for illustration only, and are not limited by this structure in the patent application; the bottle rack includes a main frame The body 10 and a spacer 20 selectively positioned on the main frame body 10 . The main frame body 10 includes a mounting portion 11 and a supporting portion 12, wherein, the mounting portion 11 is formed with a longitudinal groove 13, and the mounting portion 11 is also provided with a groove 14, the width of the groove 14 is greater than the width of the longitudinal groove 13 , and the longitudinal through groove 13 is arranged along the centerline of the groove 14 . The limit frame 20 includes a sliding portion 21 attached to the mounting portion 11, and a first bracket 22 and a second bracket 23 extend from the top edge and the bottom edge of the sliding portion 21 respectively, wherein the first bracket 22 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com