A kind of preparation method of cholesteric liquid crystal composite film

A technology of cholesteric liquid crystal and composite film, which is applied in the field of liquid crystal application technology, can solve problems such as difficult control and complicated process, and achieve the effect of stabilizing a specific optical reflection mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

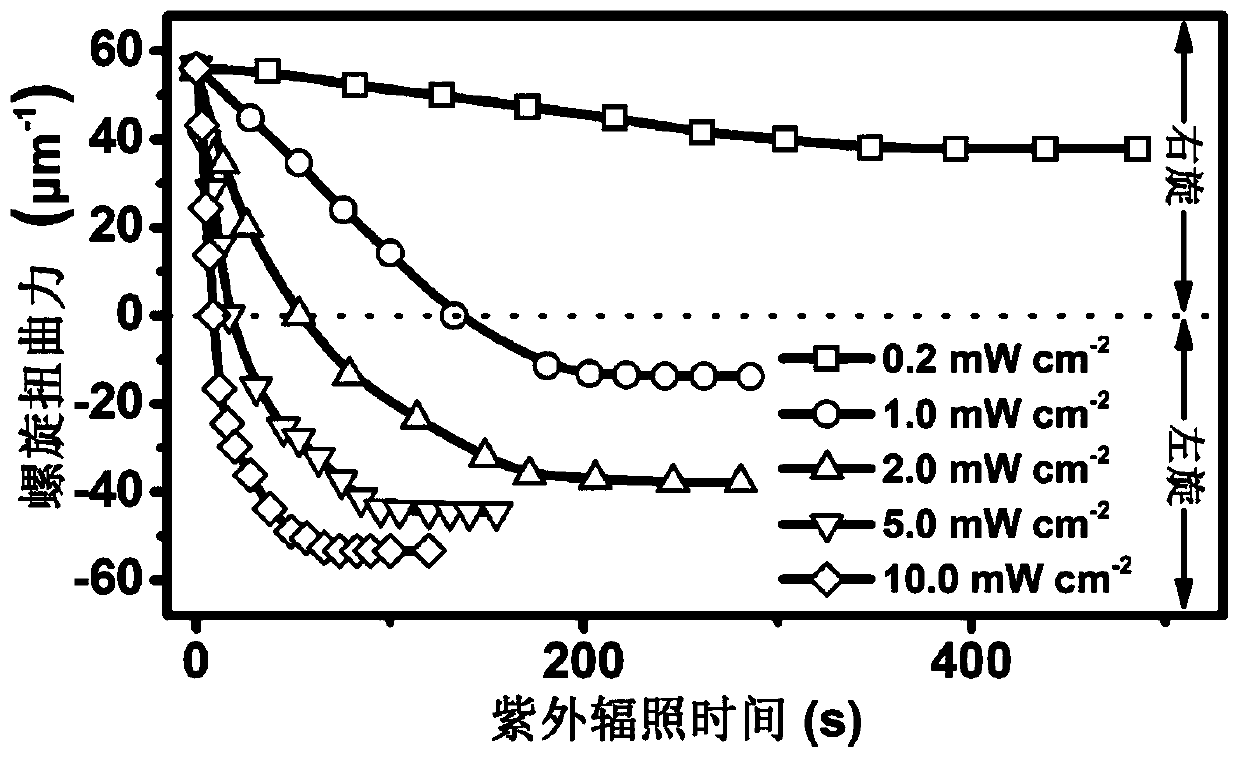

Embodiment 1

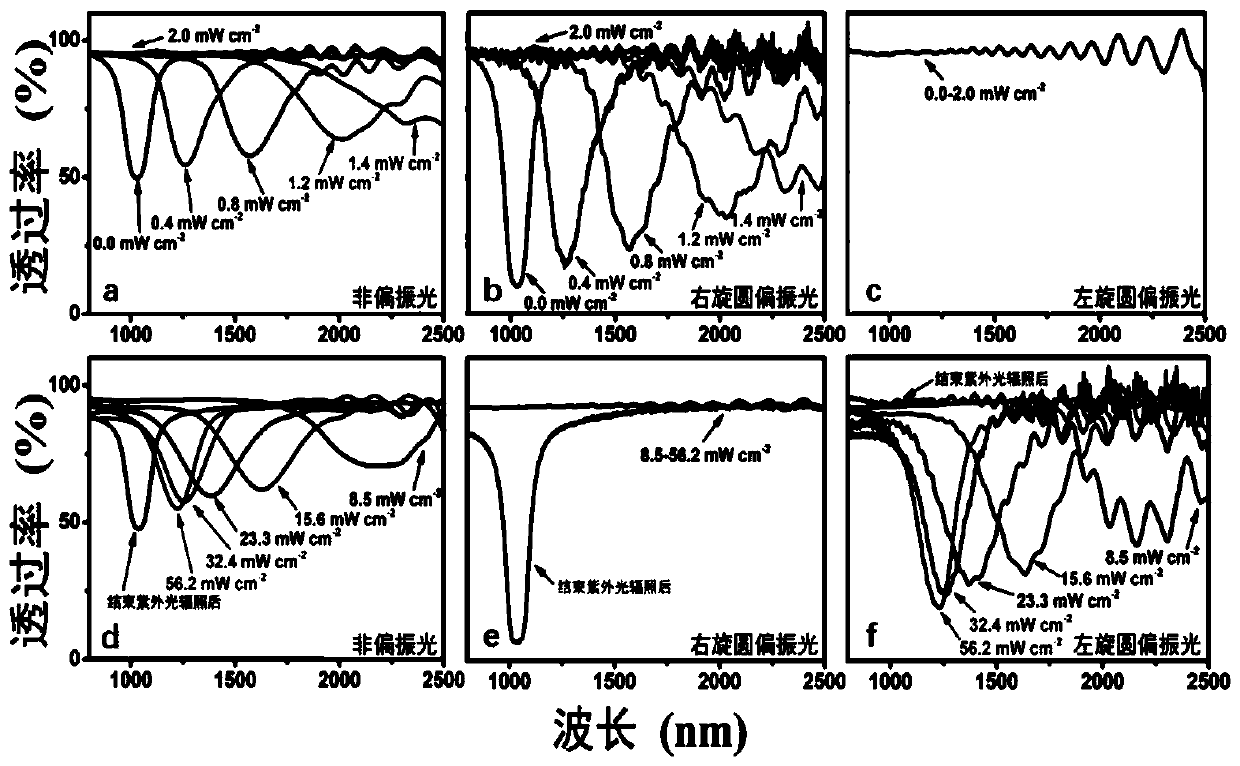

[0041] Firstly, the glass is cleaned, and a liquid crystal cell with a thickness of 10 μm is fabricated with the inner surface subjected to parallel rubbing orientation treatment. The composite system of chiral helicene compound M10 (right-handed) / small molecule nematic liquid crystal SLC1717 is blended according to the ratio of 3.50 / 96.50 to prepare a liquid crystal composite system with a wide N* phase temperature range. First, the liquid crystal is composited The system is poured into a parallel-oriented liquid crystal cell, using different intensities of ultraviolet light (0-56.2mW / cm 2 , 365nm) for 1.5 minutes, and then obtain liquid crystal films with different reflection bands. After stopping the ultraviolet light irradiation for 3 minutes, the reflection peak of the cholesteric liquid crystal returned to the initial position (proves that the liquid crystal composite film has recovery properties).

[0042] The non-polarized, right-handed circularly polarized, and left-...

Embodiment 2

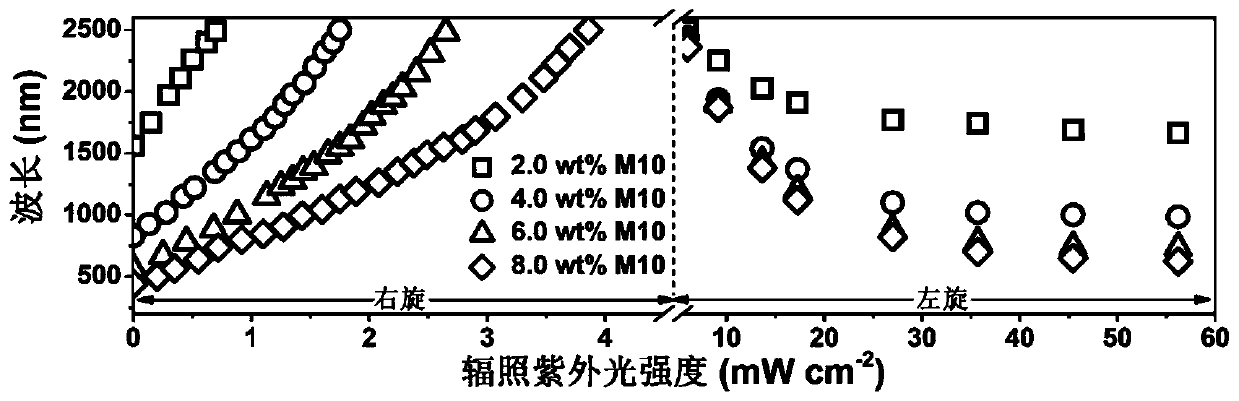

[0044] Firstly, the glass is cleaned, and a liquid crystal cell with a thickness of 10 μm is fabricated with the inner surface subjected to parallel rubbing orientation treatment. Since when the thickness of the liquid crystal film material is 10 μm, the gradient of the helical pitch from top to bottom in the system under ultraviolet light irradiation changes very little, and the helical pitch is approximately uniformly distributed, so by adjusting the chiral helicene compound (right-handed) / The proportion of chiral helicene compounds in the composite system of small molecule nematic liquid crystal SLC1717, such as the mass fraction is 2.00wt%-8.00wt%, and then the liquid crystal composite system is poured into the liquid crystal cell of parallel orientation, using different intensities Ultraviolet light (0-56.2mW / cm 2 , 365nm) for 1 minute, the controllable range of the reflection peak can be extended from the infrared light band to the visible light band and the ultraviolet...

Embodiment 3

[0048] Firstly, the glass is cleaned, and a liquid crystal cell with a thickness of 35 μm is fabricated with the inner surface subjected to parallel rubbing orientation treatment. The composite system of chiral helicene compound (right-handed) / small molecule nematic liquid crystal SLC1717 is blended according to the ratio of 3.50 / 96.50 to prepare a liquid crystal composite system with a wide N* phase temperature range. First, the liquid crystal composite system Poured into a parallel-oriented liquid crystal cell, using different intensities of ultraviolet light (0-100.0mW / cm 2 , 365nm) irradiation for 1 minute, and then obtain liquid crystal films with different reflection modes. After stopping the ultraviolet light irradiation for 2 minutes, the reflection peak of the cholesteric liquid crystal returned to its original position.

[0049] The non-polarized, right-handed circularly polarized, and left-handed circularly polarized transmission spectra of the liquid crystal film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com