Water ring vacuum pump connecting structure

A technology of water ring vacuum pump and connection structure, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve the problems of vacuum pumps scattered, no positioning stop, and inconvenient maintenance. Low, fast pumping speed, cost-effective and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

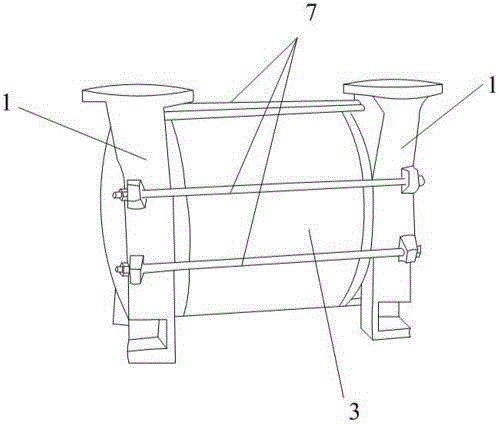

[0015] Such as figure 1 Shown is the connection structure of a traditional water ring vacuum pump, which includes a pump body 3 in the middle and two pump covers 1 located at both ends of the pump body 3, and a distribution plate 2 located at the end of the pump body 3 close to the pump cover 1. Both ends of the pull rod 7 are provided with external threads, and the end of the pump cover 1 far away from the pump body 3 is provided with a protrusion with an internal thread hole. Parts of the vacuum pump.

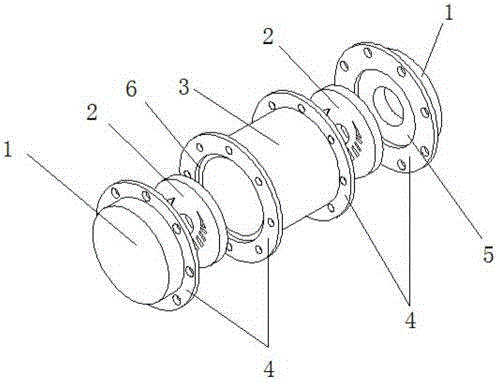

[0016] Such as figure 2 Shown is an exploded view of the connection structure of the water ring vacuum pump provided by the embodiment of the present invention. In this embodiment, two pump covers 1 are respectively provided at both ends of the pump body 3, and the two ends of the pump body 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com