Drivable working machine and method for operating same

A working machine, working position technology, applied in the direction of earth movers/shovels, cranes, transportation and packaging, etc., to achieve the effect of reduced downtime, high deflection stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

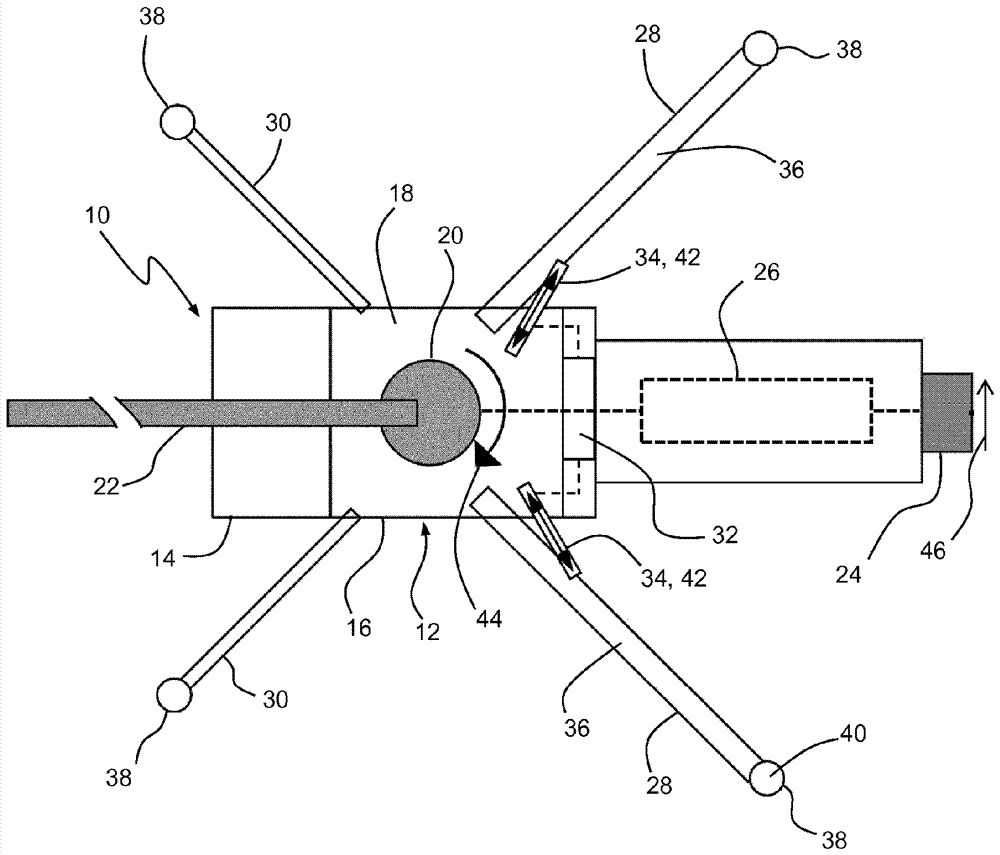

[0026] exist figure 1 The truck-mounted concrete pump 10 illustrated in includes a transport vehicle 12 with a cab 14 and a frame 16 , a superstructure frame (Aufbaurahmen) or load-carrying structure 18 , a multi-linkage that can be rotated about a vertical axis (Hochachse) by means of a rotation mechanism 20 Mehrgliedrigen concrete distribution rod 22, a delivery pump 26 configured as a double-cylinder piston pump for conveying liquid concrete, coupled between the filling funnel 24 and said concrete distribution rod 22, and a plurality of support legs 28, 30 It serves to support the load-bearing structure 18 in a working position provided for the concrete pouring operation. In addition, in order to achieve compensation of undesired rotational deflections or deflection vibrations of the load-bearing structure 18 during the pouring operation, a figure 1 The compensating means 32 are only shown symbolically.

[0027] In the supporting configuration shown, the rear supporting l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com