Structural Assembly

A technology of structural components and components, applied in the direction of connecting components, aircraft parts, threaded fasteners, etc., can solve the problem of increasing the overall cost of aircraft manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

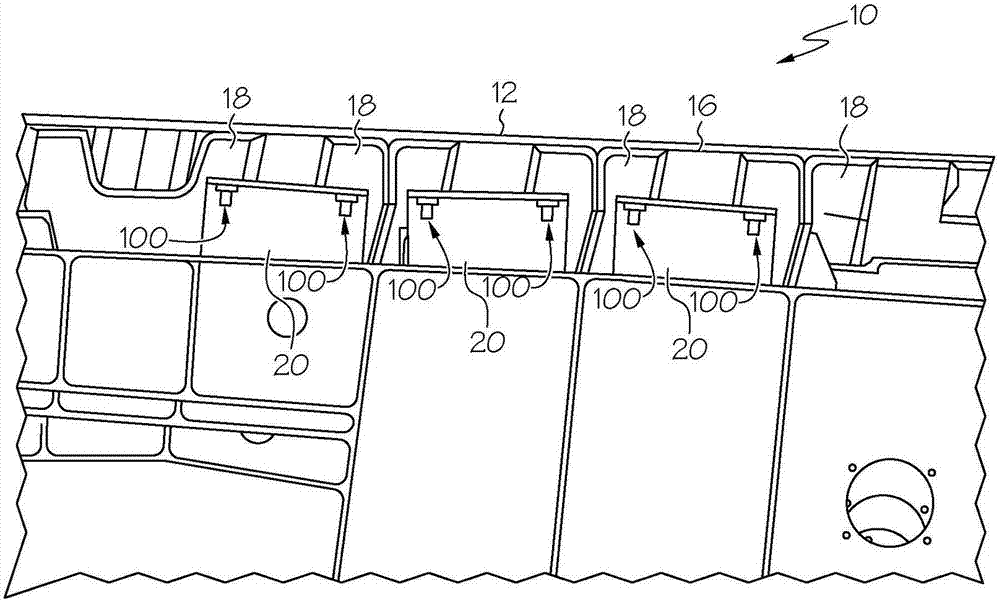

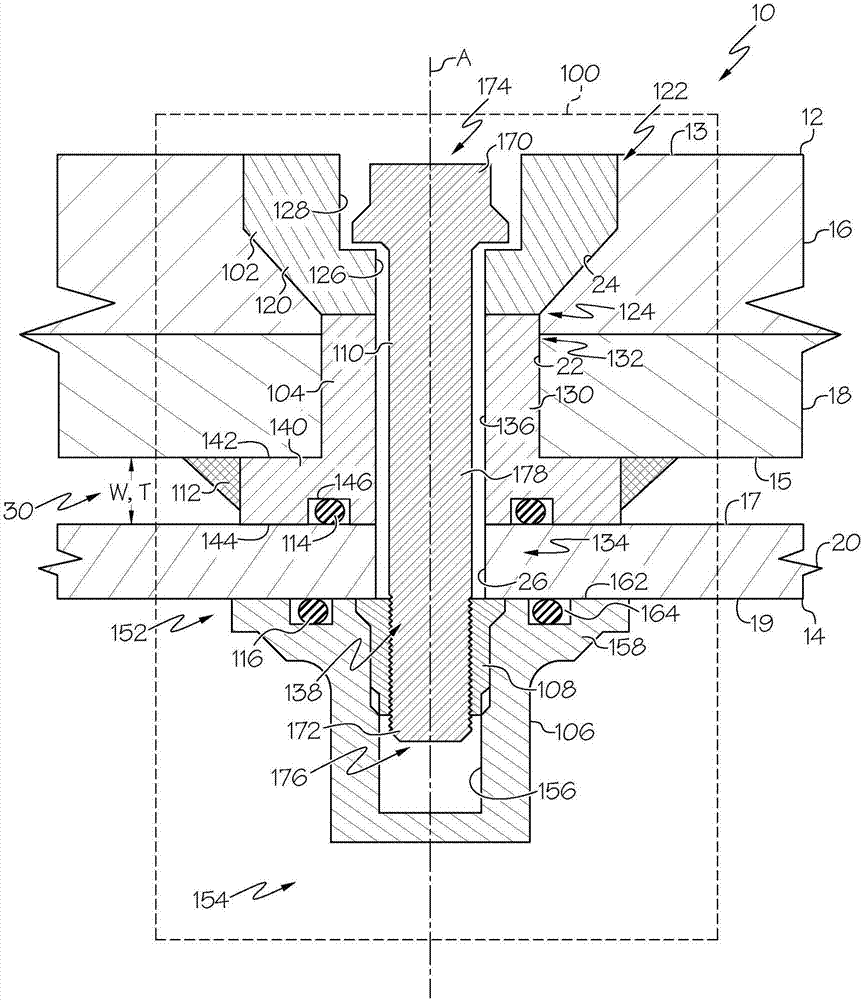

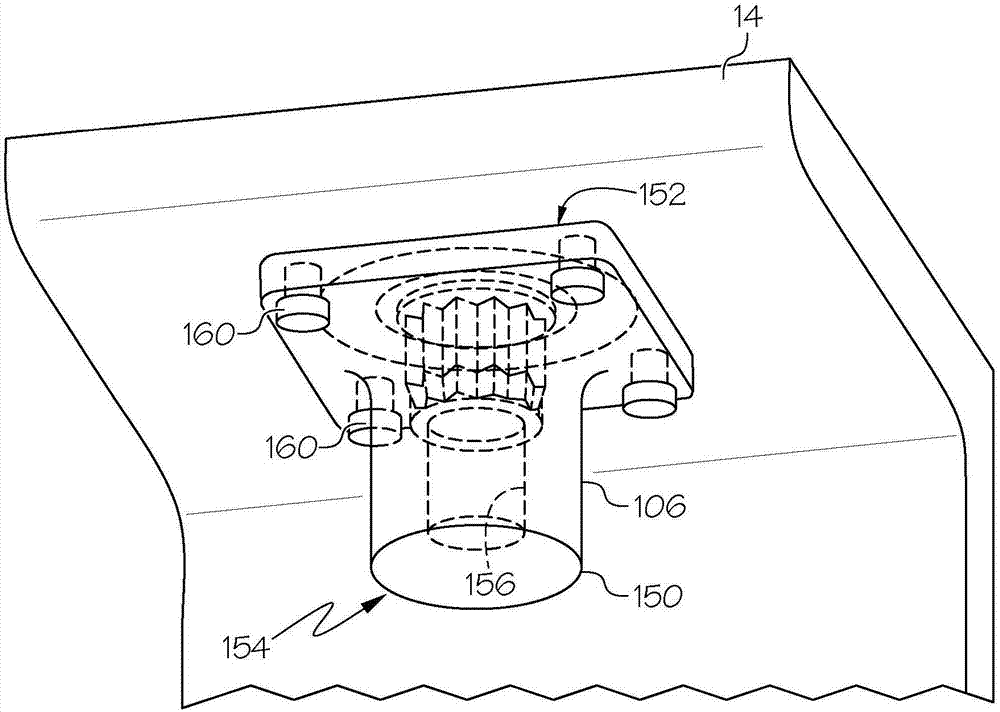

[0018] refer to figure 1 and figure 2 , discloses a fluid-tight mechanical fastening system, generally indicated at 100, and a structural assembly, generally indicated at 10, comprising a connection to a second member using the disclosed fluid-tight mechanical fastening system 100 14 of the first member 12 . As described in greater detail herein, the disclosed fluid-tight mechanical fastening system 100 can facilitate externally connecting the first member 12 to the second member 14 (from the outer side 13( figure 2 )), while maintaining the fluid impermeability of the first member 12.

[0019] In one particular application, the disclosed structural assembly 10 may be a wing of an aircraft, such as a passenger or commercial aircraft. Thus, first member 12 of structural assembly 10 may include an aircraft wing skin panel 16 and optionally a stringer 18 connected to skin panel 16 , while second member 14 of structural assembly 10 may include spar ribs 20 . However, those s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com