A construction method for tunnel drainage system of steel-frp composite corrugated pipe

A technology for tunnel drainage and construction methods, which is applied in the directions of drainage, pipes, and pipe components, and can solve the problems of brittle failure and low strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be described below in conjunction with examples.

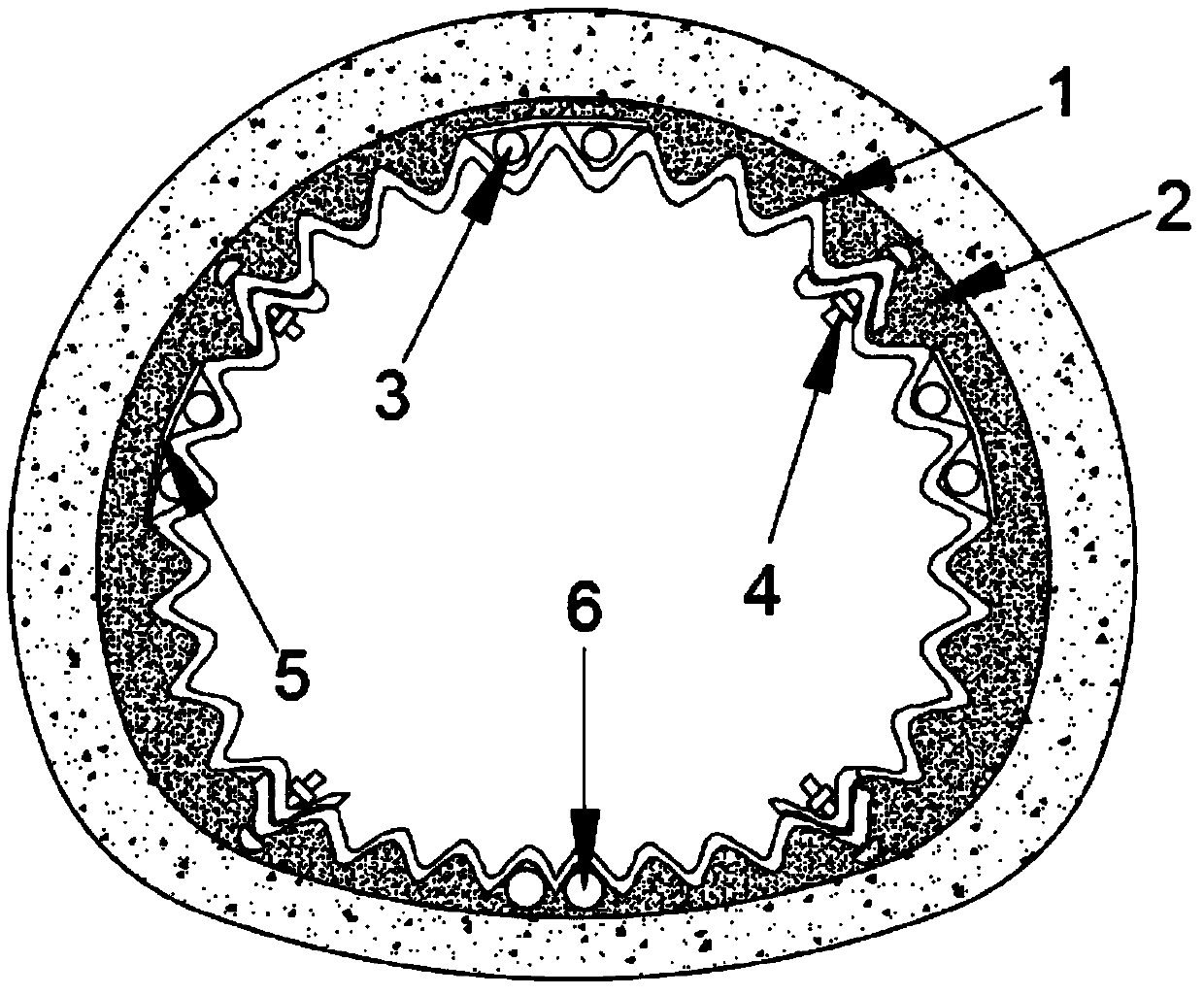

[0021] Such as figure 1 As shown, the tunnel support is spliced by four composite FRP corrugated plates 1 embedded with steel, and the corrugated plates are connected by high-strength bolts 4 . A blind pipe 3 is arranged at the trough of the corrugated pipe, and a waterproof filter plate 5 is fixed, the drain pipe 3 is collected in the central drain pipe 6, and concrete 2 is poured between the corrugated pipe and the surrounding rock.

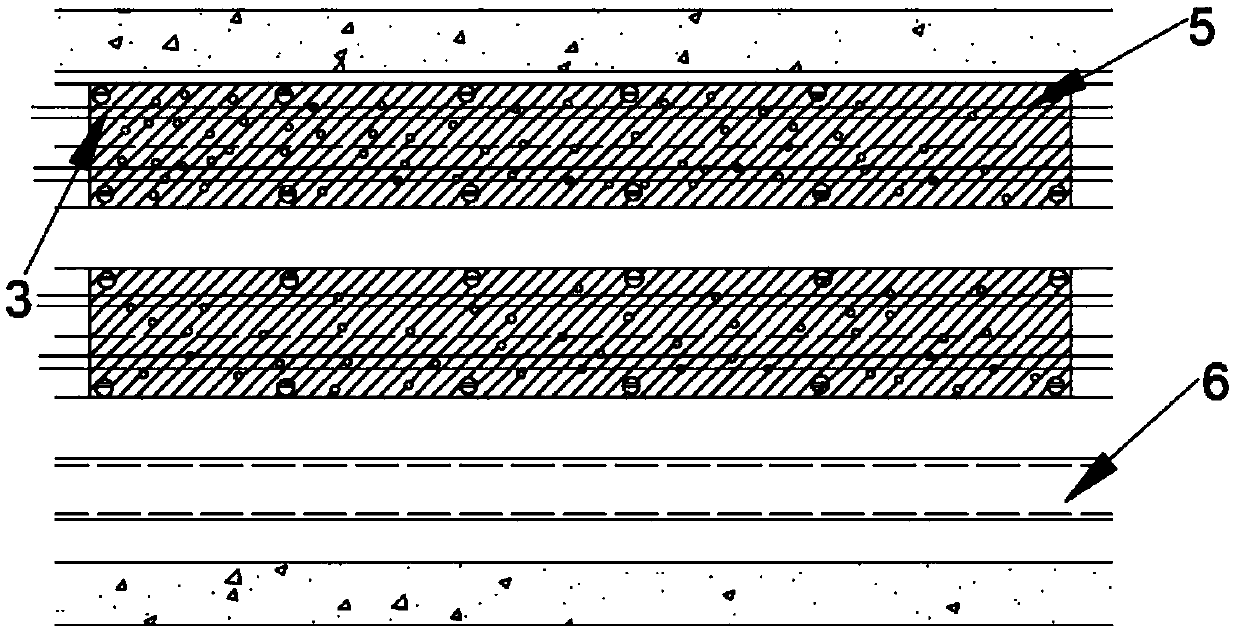

[0022] Such as figure 2 As shown, the drain pipe 3 is built into the cavity of the corrugated pipe trough and the waterproof filter plate, and the number of the drain pipe 3 can be appropriately increased or decreased according to the hydrological conditions, and the waterproof filter plate 5 is only fixed on the part with the drain pipe.

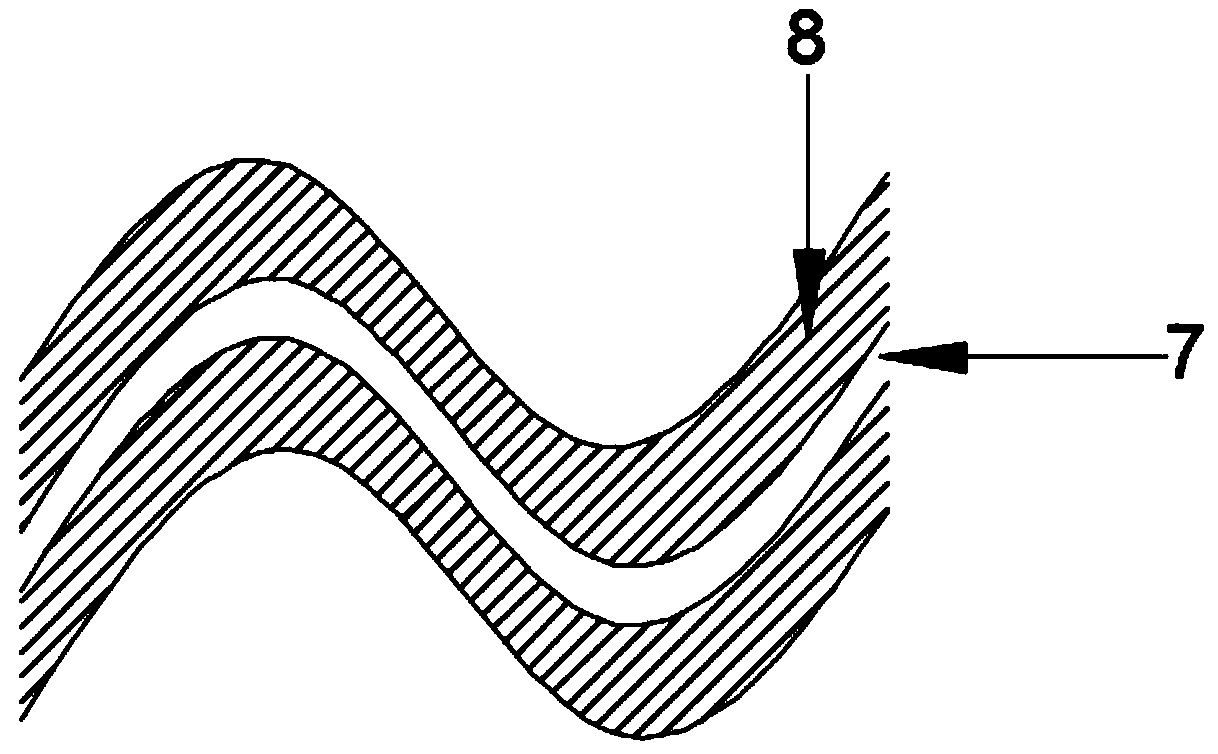

[0023] Such as image 3 As shown, the composite FRP corrugated plate 1 embedded with steel is formed by pultruding and therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com