A method and device for measuring characteristic parameters of streak-like morphology

A technology of shape characterization and parameters, which is applied in the field of measurement of striation-like shape characterization parameters, can solve the problem of inability to quantitatively analyze the severity of striae-like shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the above objectives, features, and advantages of the present application more obvious and understandable, the following describes the embodiments of the present application in further detail with reference to the accompanying drawings and specific implementations.

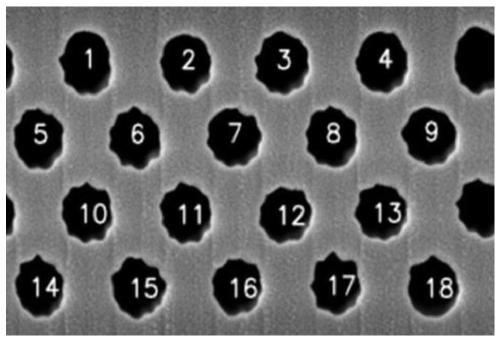

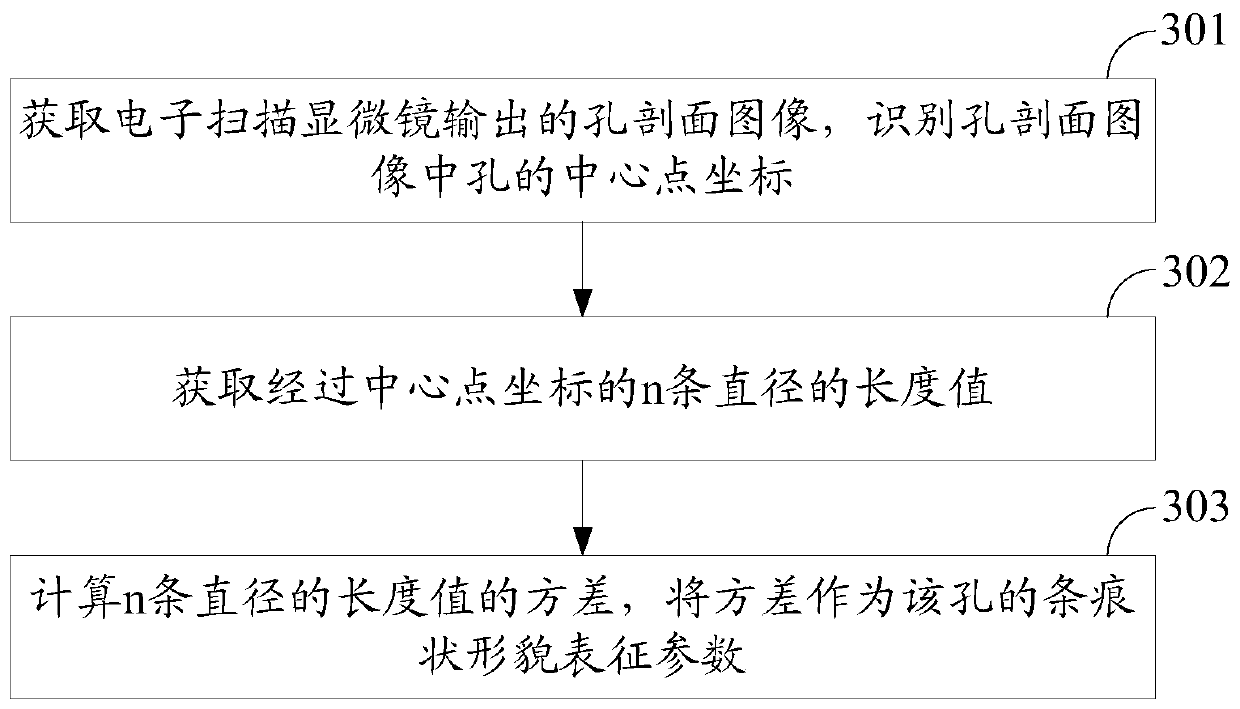

[0049] In practical applications, deep hole etching can be performed on the wafer to process certain electronic devices. In the deep hole etching process, the contour of the etched deep hole may have a streak-like appearance. In order to solve the technical problem that the severity of the streak-like morphology cannot be quantitatively analyzed in the prior art, the embodiments of the present application provide a method and device for measuring the streak-like morphology characterization parameters, by fitting the deep hole etching morphology The boundary of the medium and deep hole obtains the coordinates of the center point of the deep hole. By calculating the length values of the multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com