Six-freedom-degree chewing force control and monitoring system

A monitoring system and chewing force technology, which is applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of low reliability of chewing simulation results and low accuracy of chewing simulation, and achieve simple structure, low cost, and reduced overall effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

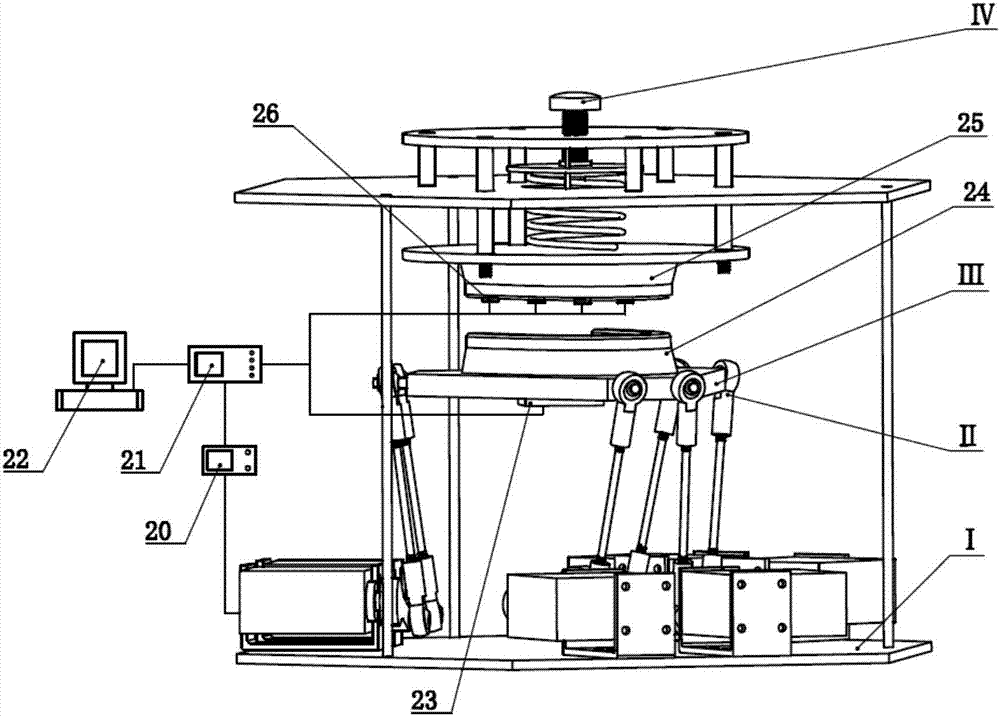

[0048] In practice, the masticating robot includes a static platform I, six driving devices II, a booster device IV, a mandibular motion platform III and a motion control system.

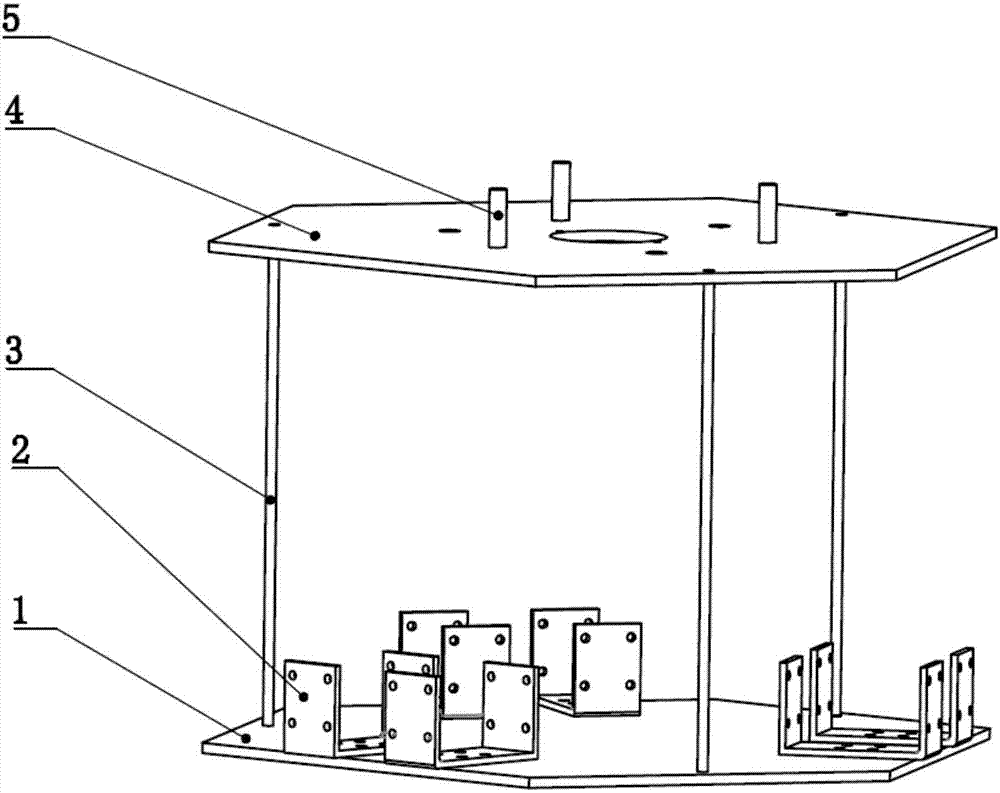

[0049] Such as figure 2 As shown, the static platform includes a lower support plate 1, a steering gear bracket 2, an upper and lower plate support 3, an upper support plate 4, and an afterburner support 5. Three upper and lower plank supports 3 are evenly distributed on the circumference between the lower support plate 1 and the upper support plate 4, and the two ends are fixedly connected with the lower support plate 1 and the upper support plate 4 by flat head bolts respectively. The six steering gear brackets 2 are in groups of two, and three groups are evenly distributed on the lower support plate in a circle. There are holes on the steering gear bracket 2, which are connected to the lower support plate 1 through flat head bolts and nuts. The three booster supports 5 are evenly distributed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com