Active component substrate

A technology of active components and substrates, applied in electrical components, electric solid-state devices, semiconductor devices, etc., can solve the problem of poor display, difficult alignment of the film layer belonging to the scanning line and the film layer belonging to the transparent electrode, and the wrong edge of the measurement system. video, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

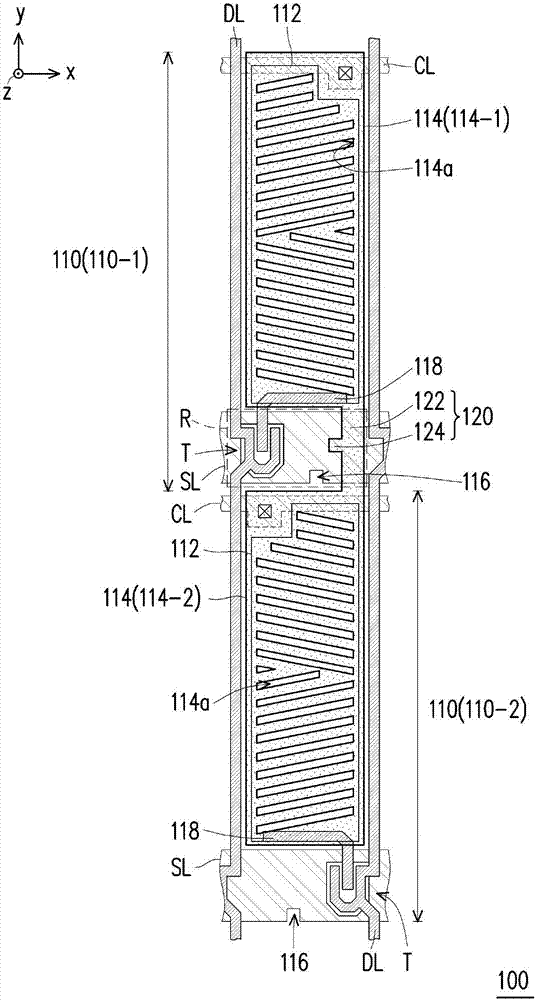

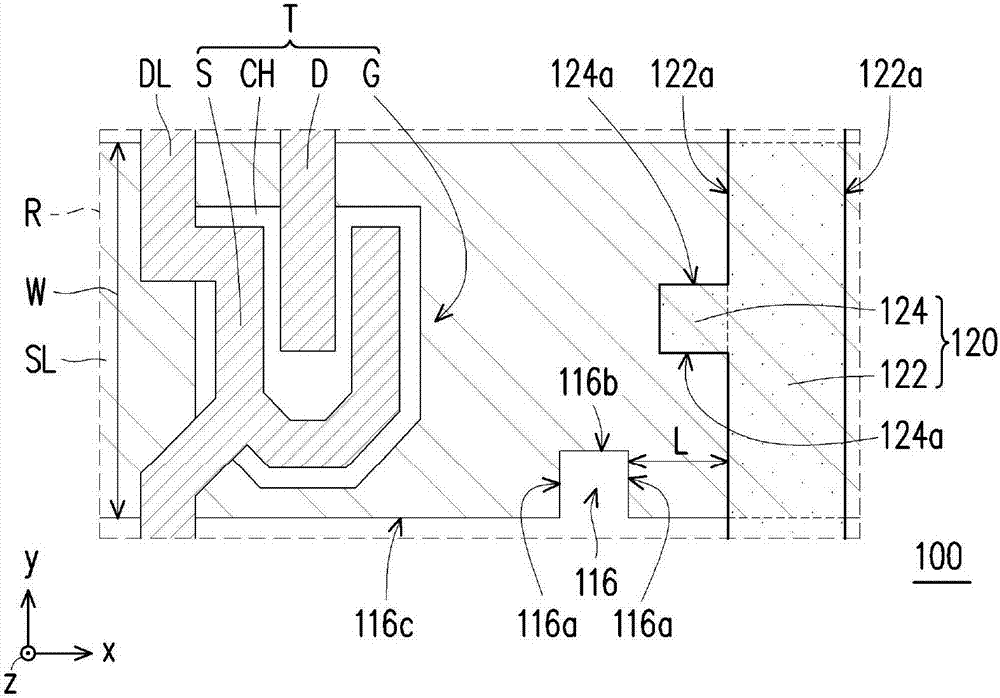

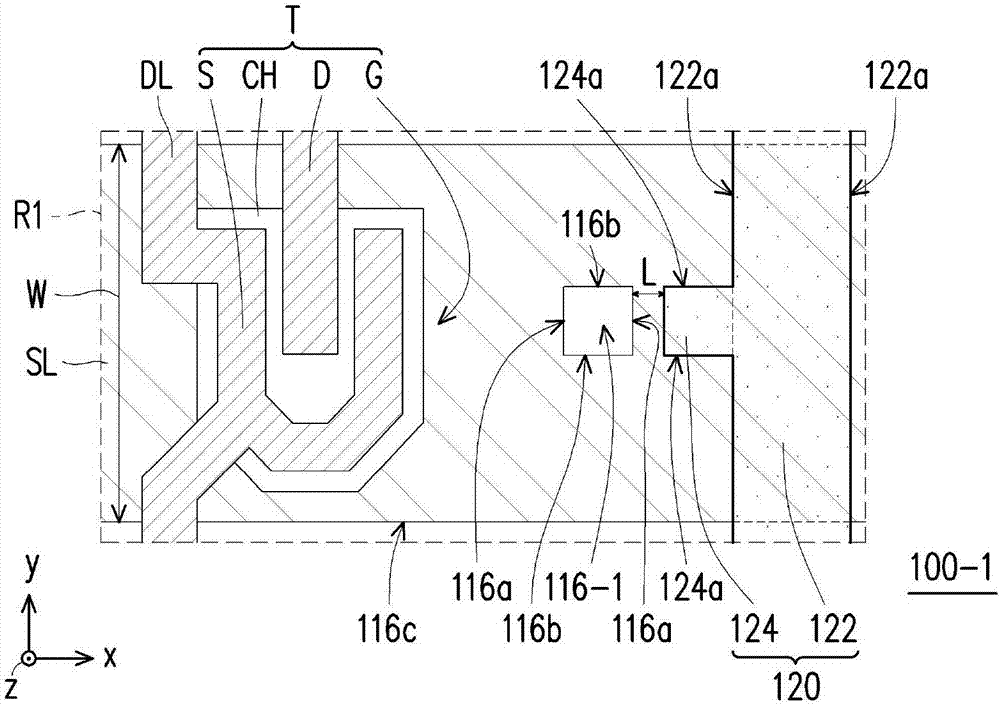

[0057] figure 1 It is a schematic top view of an active device substrate according to an embodiment of the present invention. figure 2 for figure 1 An enlarged schematic view of a part R of the active device substrate 100 of FIG. Please refer to figure 1 and figure 2 , the active device substrate 100 includes a plurality of pixel units 110 and a preset pattern 120 . A plurality of pixel units 110 and a predetermined pattern 120 are disposed on a substrate (not shown). The base is mainly a component for supporting the active device substrate 100 . In this embodiment, the material of the substrate can be glass, quartz, organic po...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap