Galvanizing system for wire electrode applied to mold processing

A technology for mold processing and electrode wire, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve problems such as unfavorable collection, uneven galvanizing, and thermal deformation of core materials, and achieve uniform galvanizing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

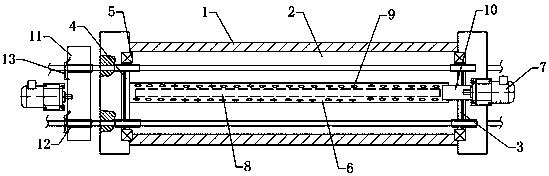

[0019] The reference signs in the accompanying drawings of the specification include: the chassis body 1, the horizontal pipe 2, the first end cover 3, the second end cover 4, the bearing 5, the rotating shaft 6, the servo motor 7, the hollow cavity 8, the liquid outlet 9, Liquid zinc feeder 10, turntable 11, round hole 12, glue 13.

[0020] The embodiment is basically as attached figure 1 Shown: the galvanizing system of electrode wire for mold processing, including a cabinet body 1 and a galvanizing unit arranged in the cabinet body 1, the galvanizing unit includes a horizontal pipe 2 with openings at both ends, and a The first end cap 3 and the second end cap 4 at both ends of the pipe 2 are installed on the horizontal pipe 2 through the bearing 5, and the horizontal pipe 2 is provided with a rotating shaft at the central axis 6. The rotating shaft 6 is driven by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com