A hoisting tool for propeller blades

A hoisting and tooling technology, which is applied in the field of hoisting and hoisting of blades, can solve the problem that the blades are not easy to be hoisted, and achieve the effect of achieving balanced, stable and balanced hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

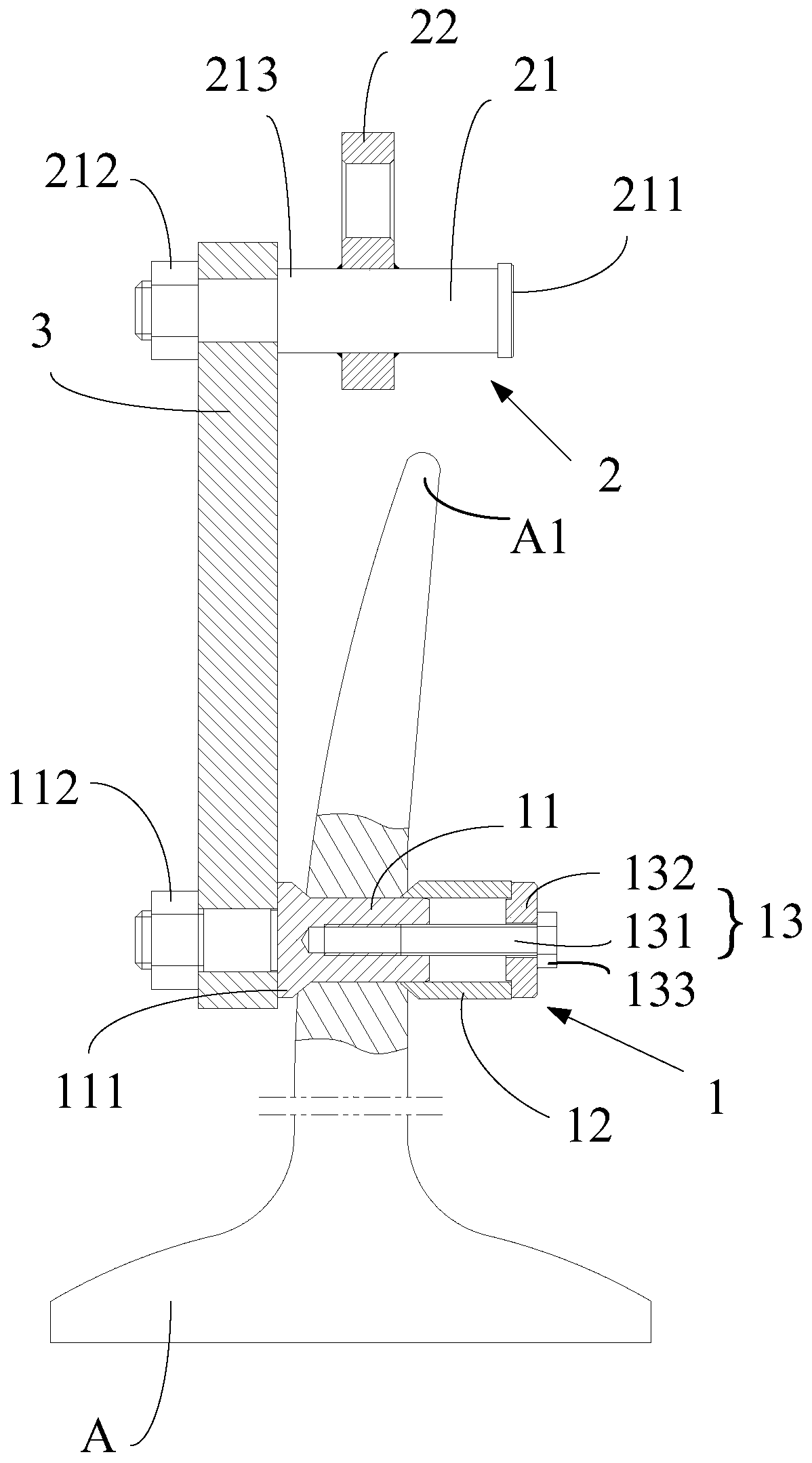

[0029] An embodiment of the present invention provides a hoisting tool for a blade. A hoisting hole is pre-opened on the blade, and the hoisting hole is used to cooperate with the hoisting tool. Such as figure 1 As shown, the hoisting tool includes a mounting part 1 , a hoisting part 2 and a connecting arm 3 .

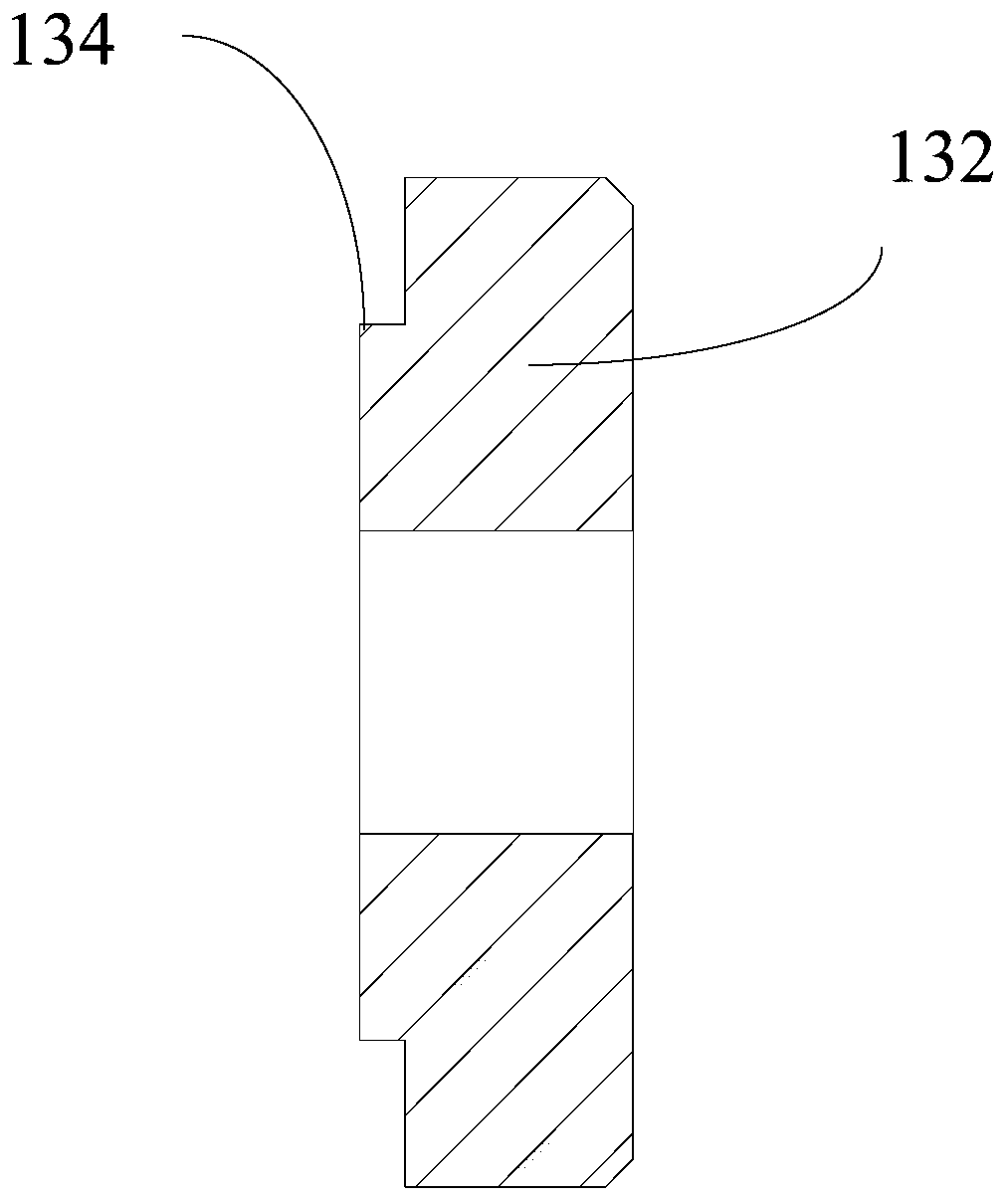

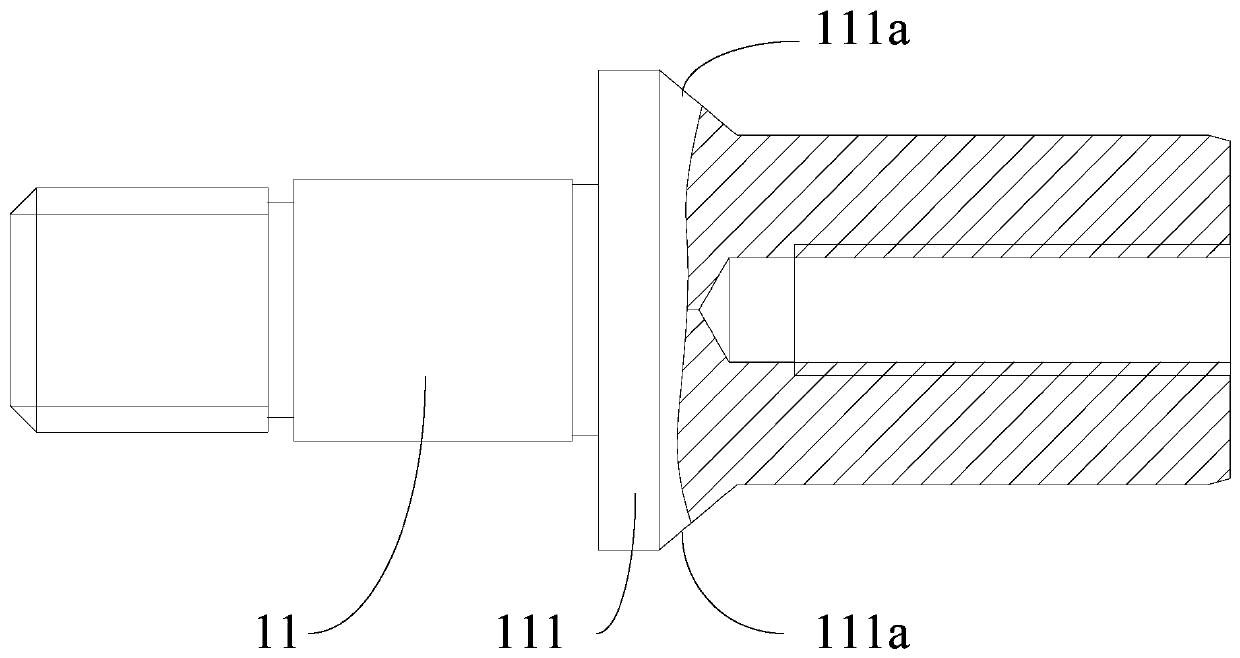

[0030] Wherein, the mounting part 1 includes a first pin shaft 11, a bushing 12 and a fixing part 13, one end of the first pin shaft 11 is installed on one end of the connecting arm 3, and the other end of the first pin shaft 11 is used to pass through the paddle A In the hoisting hole on the top, the middle part of the first pin shaft 11 is provided with a limit protrusion 111, and the limit protrusion 111 is against one side of the blade A, and one end of the bush 12 is sleeved on the other end of the first pin shaft 11 and Against the other side of the paddle A, the bushing 12 is arranged on the first pin shaft 11 through the fixing member 13 .

[0031] The hoisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com