Lever type automatic closing valve

An automatic closing, lever-type technology, applied in the directions of sliding valves, valve details, valve devices, etc., can solve the problems of high work intensity, danger of power lines, time-consuming and laborious, etc., and achieve the effect of improving loading and unloading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

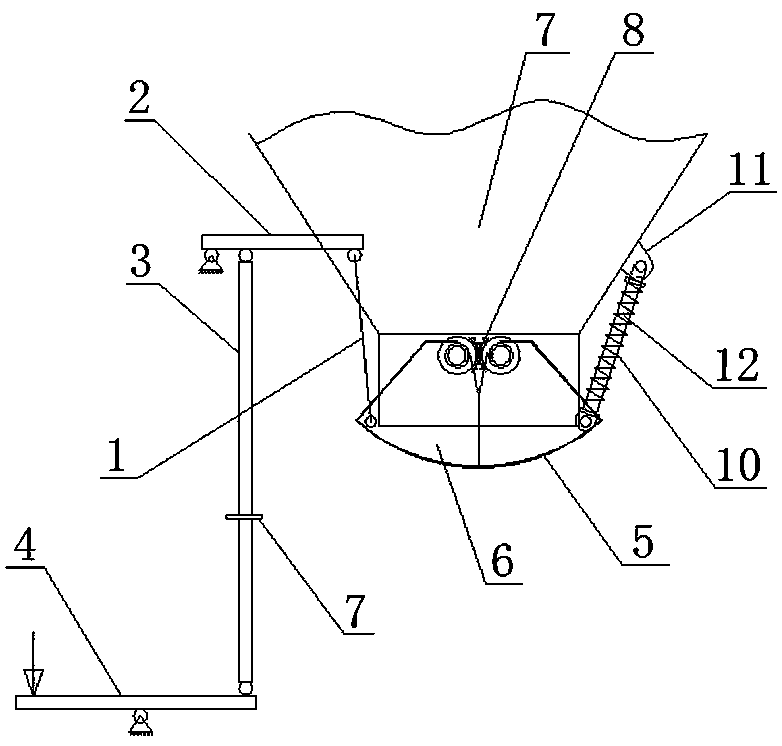

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0013] Such as figure 1 As shown, a lever-type automatic closing valve of the present invention includes two valve panels, a rope 1, a first lever 2, a connecting rod 3 and a second lever 4, and the two valve panels include arc panels 5 and two sides The fan-shaped side plate 6, the arc-shaped panel 5 of the two valve door panels just closes the discharge opening at the lower end of the hopper 7, the fan-shaped side plates 6 on both sides are fixed on both sides of the arc-shaped panel 5 and the upper end of the fan-shaped side plate 6 is hinged on the hopper 7 On the outside of the discharge port, on the inside of the hinged shafts of the two valve panels, there is a gear 8 that meshes with each other. One end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com