Vibration Actuators, Lens Drivers, and Ultrasonic Motors

An actuator and vibration technology, which is applied in the field of vibration actuators, lens drive devices and ultrasonic motors, can solve the problem of unstable driving characteristics of vibration actuators, and achieve the effect of stable driving characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

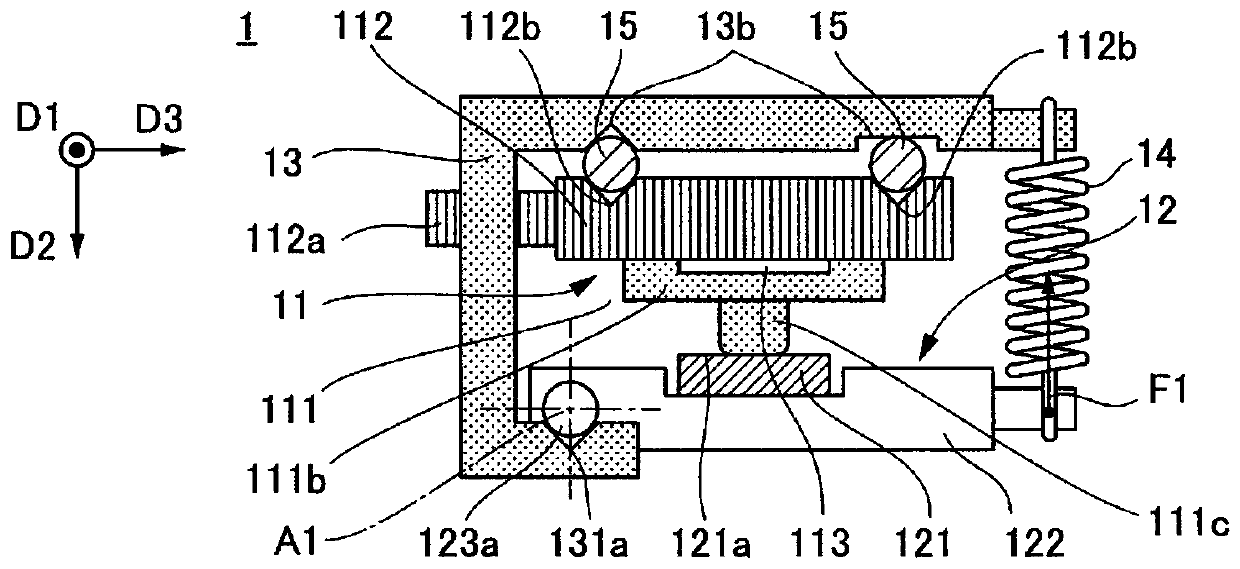

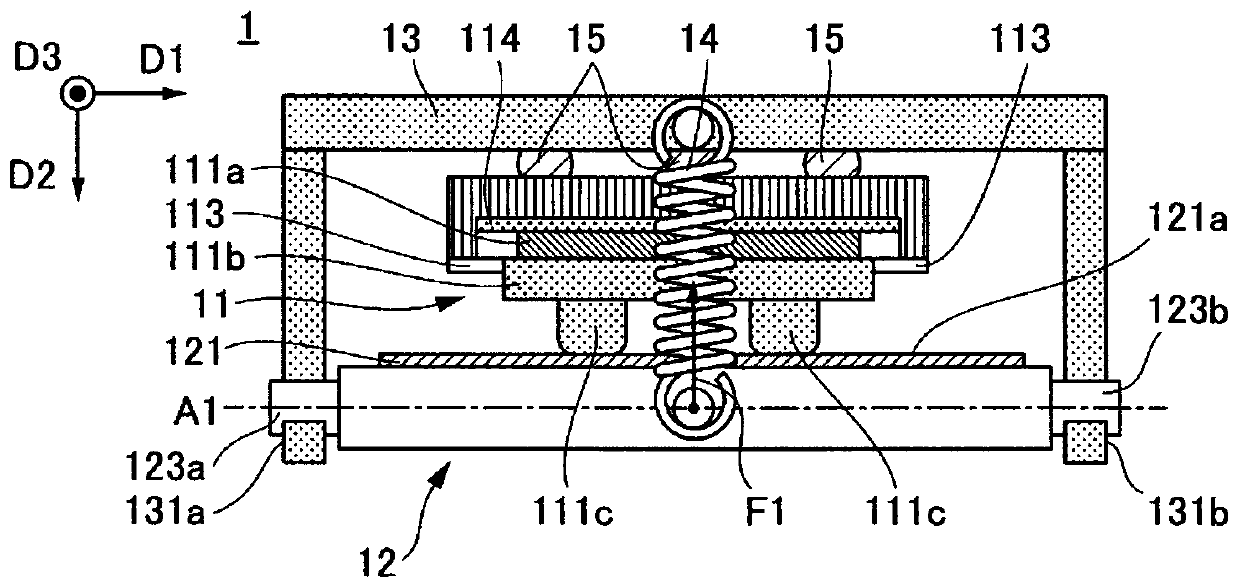

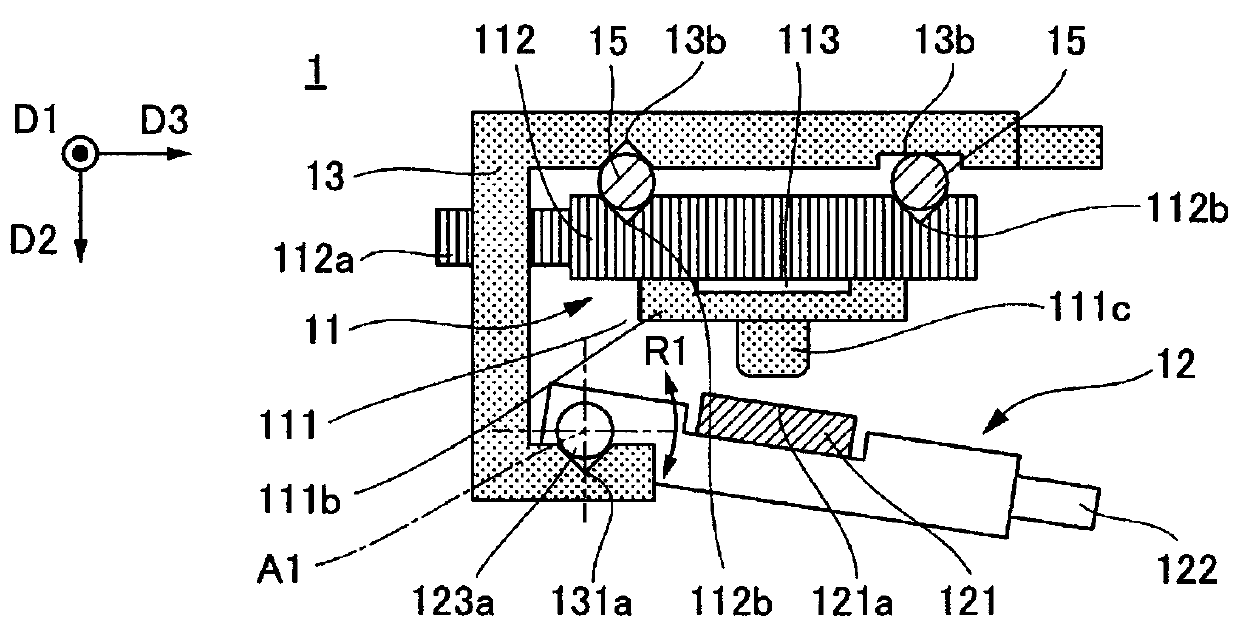

[0037] Figure 1A to Figure 1C It is a figure which shows the structure of a vibration actuator. Figure 1A to Figure 1C The illustrated vibration motor 1 is an ultrasonic motor used as a vibration actuator having a vibrator that ultrasonically vibrates by application of a high-frequency voltage. Of course, the scope of application of the present invention is not limited to ultrasonic motors. In addition, the present invention can be applied to a lens driving device including the vibration motor 1 .

[0038] Figure 1A shows the driving direction from the vibrating motor 1 ( Figure 1A to Figure 1C The direction D1) is shown to observe the state. Figure 1B A state viewed from the side in the driving direction of the vibration motor 1 is shown. The vibration motor 1 includes a first member 11 , a second member 2 , a third member 13 and a pressurizing unit 14 .

[0039] The first member 11 includes a vibrator 111 vibrating by applying AC (alternating current) voltage, a vi...

no. 2 approach

[0064] Figure 3A to Figure 3C is a diagram showing the configuration of a vibration actuator according to a second embodiment. Figure 3A to Figure 3C The illustrated vibration motor 2 is an ultrasonic motor, which is a vibration actuator having a vibrator that vibrates ultrasonically by application of a high-frequency voltage. Of course, the scope of application of the present invention is not limited to ultrasonic motors. In addition, the present invention can be applied to a lens driving device including the vibration motor 2 .

[0065] Figure 3A shows the driving direction from the vibrating motor 2 ( Figure 3A to Figure 3C The direction D1) is shown to observe the state. Figure 3B A state viewed from the side in the driving direction of the vibration motor 2 is shown. Figure 3C showing along Figure 3B The state observed in the direction indicated by the arrow P shown. The vibration motor 2 includes a first member 21 , a second member 22 , a third member 23 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com