Plant-based copper electroplating wastewater demulsifier

A copper electroplating, plant-based technology, applied in the direction of immiscible liquid separation, etc., can solve the problems of no treatment method, active ingredient failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

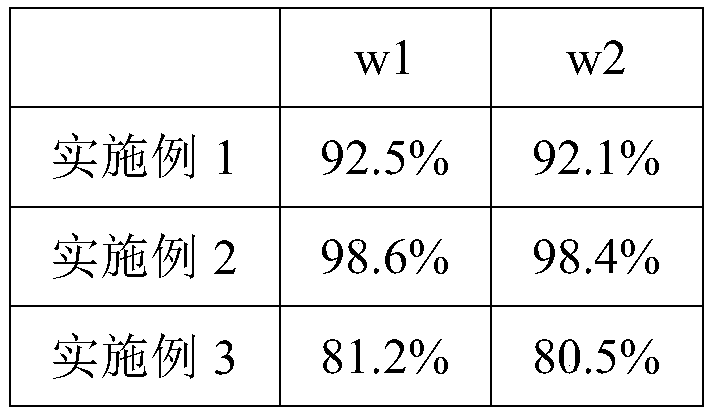

Embodiment 1

[0060] Plant-based demulsifier for electroplated copper sewage, in parts by weight, including 14 parts of Radix Radix Radix, 8 parts of Poria cocos extract, 10 parts of Shijunzi extract, 8 parts of chrysanthemum flower extract, 8 parts of shiitake mushroom extract, and perilla leaf extract 10 parts, 100 parts of water.

[0061] The preparation method of the Radix isatidis extract is as follows: wash 400g of Radix Radix Radix, grind into powder, add 1000mL of benzene, store at 4°C for 5h, filter with a Buchner funnel, collect the solid, add 500mL of 3wt% acetic acid, and then add 5g of sodium sulfide , maintain a constant temperature of 50°C, soak for 3 hours, filter, collect the solid, then add 500mL of distilled water, maintain a constant temperature of 50°C, soak for 3 hours, filter, collect the filtrate, and then process it through a strong acid cation exchange column, discard the effluent, and use the resin column Wash with water until the effluent is neutral, then elute w...

Embodiment 2

[0068] Plant-based demulsifier for electroplated copper sewage, in parts by weight, including 14 parts of Radix Radix Radix, 8 parts of Poria cocos extract, 10 parts of Shijunzi extract, 8 parts of chrysanthemum flower extract, 8 parts of shiitake mushroom extract, and perilla leaf extract 10 parts, 10 parts of peppermint extract, 100 parts of water.

[0069]The preparation method of the Radix isatidis extract is as follows: wash 400g of Radix Radix Radix, grind into powder, add 1000mL of benzene, store at 4°C for 5h, filter with a Buchner funnel, collect the solid, add 500mL of 3wt% acetic acid, and then add 5g of sodium sulfide , maintain a constant temperature of 50°C, soak for 3 hours, filter, collect the solid, then add 500mL of distilled water, maintain a constant temperature of 50°C, soak for 3 hours, filter, collect the filtrate, and then process it through a strong acid cation exchange column, discard the effluent, and use the resin column Wash with water until the ef...

Embodiment 3

[0077] Plant-based demulsifier for electroplated copper sewage, in parts by weight, including 14 parts of Radix Radix Radix, 8 parts of Poria cocos extract, 10 parts of Shijunzi extract, 8 parts of chrysanthemum flower extract, 8 parts of shiitake mushroom extract, and perilla leaf extract 10 parts, 100 parts of water.

[0078] The preparation method of the Radix isatidis extract is as follows: wash 400g Radix Radix Radix, grind into powder, add 1000mL of benzene, store at 4°C for 5h, filter with a Buchner funnel, collect the solid, add 500mL of 3wt% acetic acid, keep the constant temperature at 50°C, Soak for 3 hours, filter, collect the solid, then add 500mL of distilled water, keep the constant temperature at 50°C, soak for 3 hours, filter, collect the filtrate, then process it through a strong acid cation exchange column, discard the effluent, and wash the resin column with water until the effluent is Neutral, then use 0.3mol / L ammonia water to elute, collect the ammonia w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com