Construction method of seismic support and hanger based on bim+3d scanning technology

A technology of scanning technology and construction method, which is applied in the construction field of seismic supports and hangers, can solve the problems that cannot fully reflect the space occupancy and conflicts of seismic supports and hangers, so as to improve the correct rate of first-time installation, improve the pass rate, and avoid secondary The effect of secondary application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

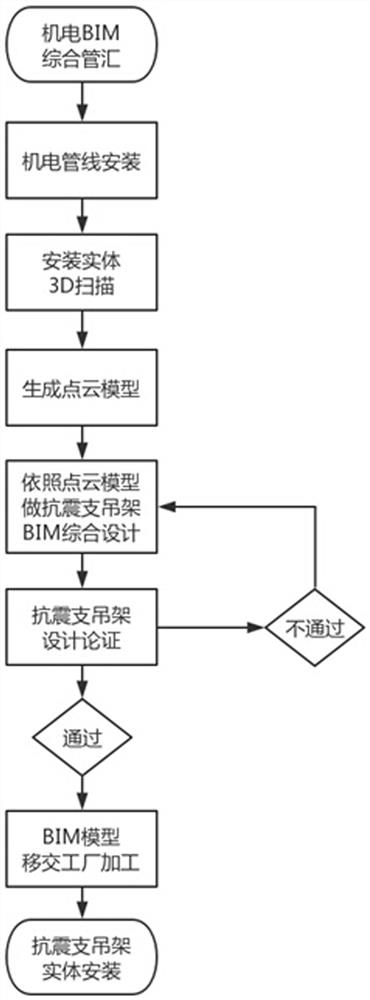

[0028] Such as figure 1As shown, the construction method of the anti-seismic support and hanger based on BIM+3D scanning technology of the present invention combines BIM technology and 3D scanning technology to guide the design and construction process of the anti-seismic support and hanger, and uses the BIM comprehensive manifold model of the electromechanical professional to guide the electromechanical professional Pipeline installation; after the installation is completed, use a 3D scanner to perform 3D scanning of the on-site physical installation; after processing, a point cloud model can be generated, which can be imported into the Revit software for viewing, and compared with the BIM comprehensive manifold model of the electromechanical professional, timely Correct the deviation and modify the model according to the actual situation of the construction site; do the BIM comprehensive design of the seismic support and hanger based on the point cloud model; the relevant tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com