Integrated layering fixator

An integrated, fixer technology, applied in horticulture, application, vegetative propagation, etc., can solve the problems: wooden stakes will be pulled up by the branches of the mother plant in rainy days, the operation process of layering is laborious and time-consuming, and it will affect the germination of buds on the branches, etc. problems, to achieve the effect of shortening the production cycle of seedlings, saving labor time and funds, and facilitating promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

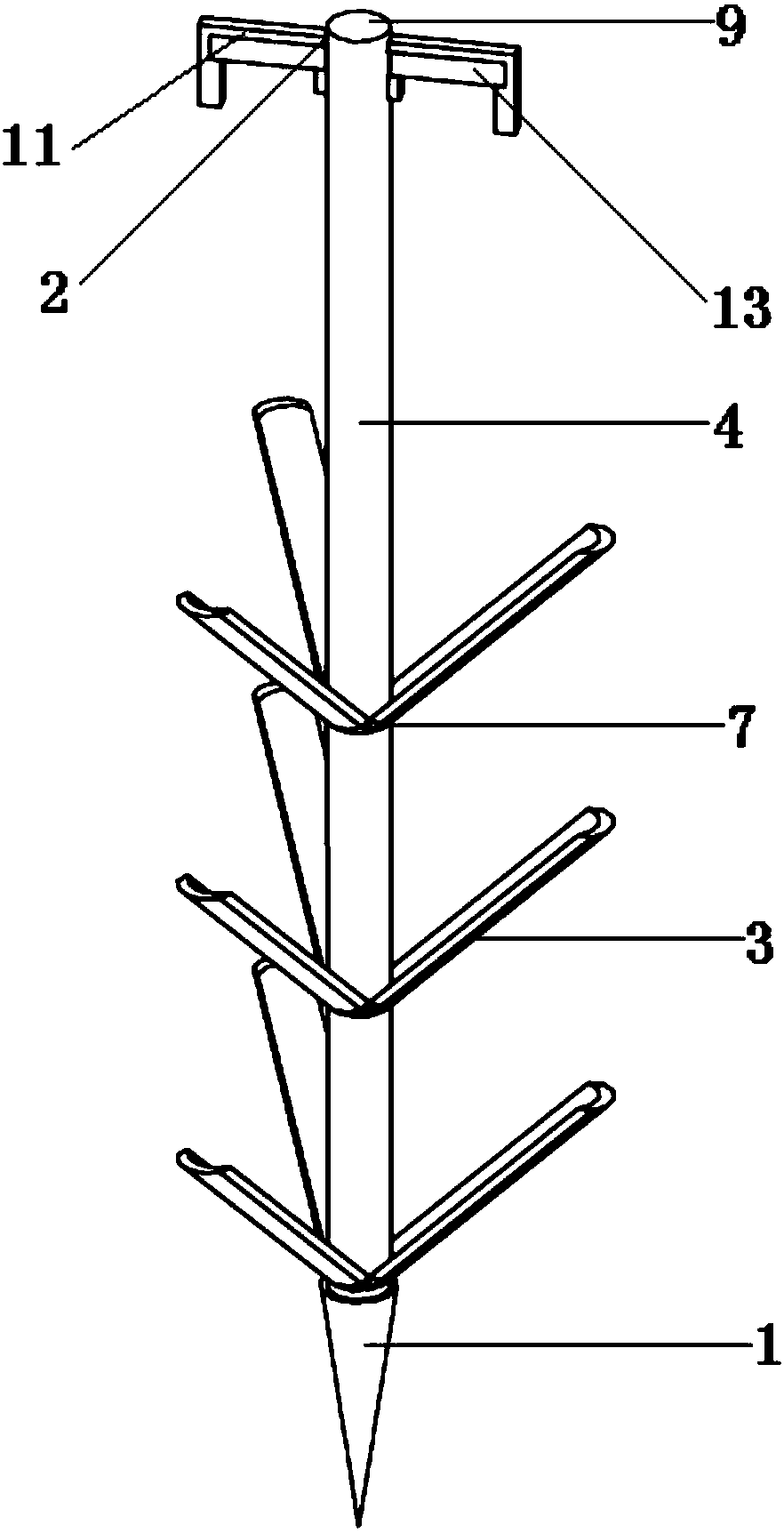

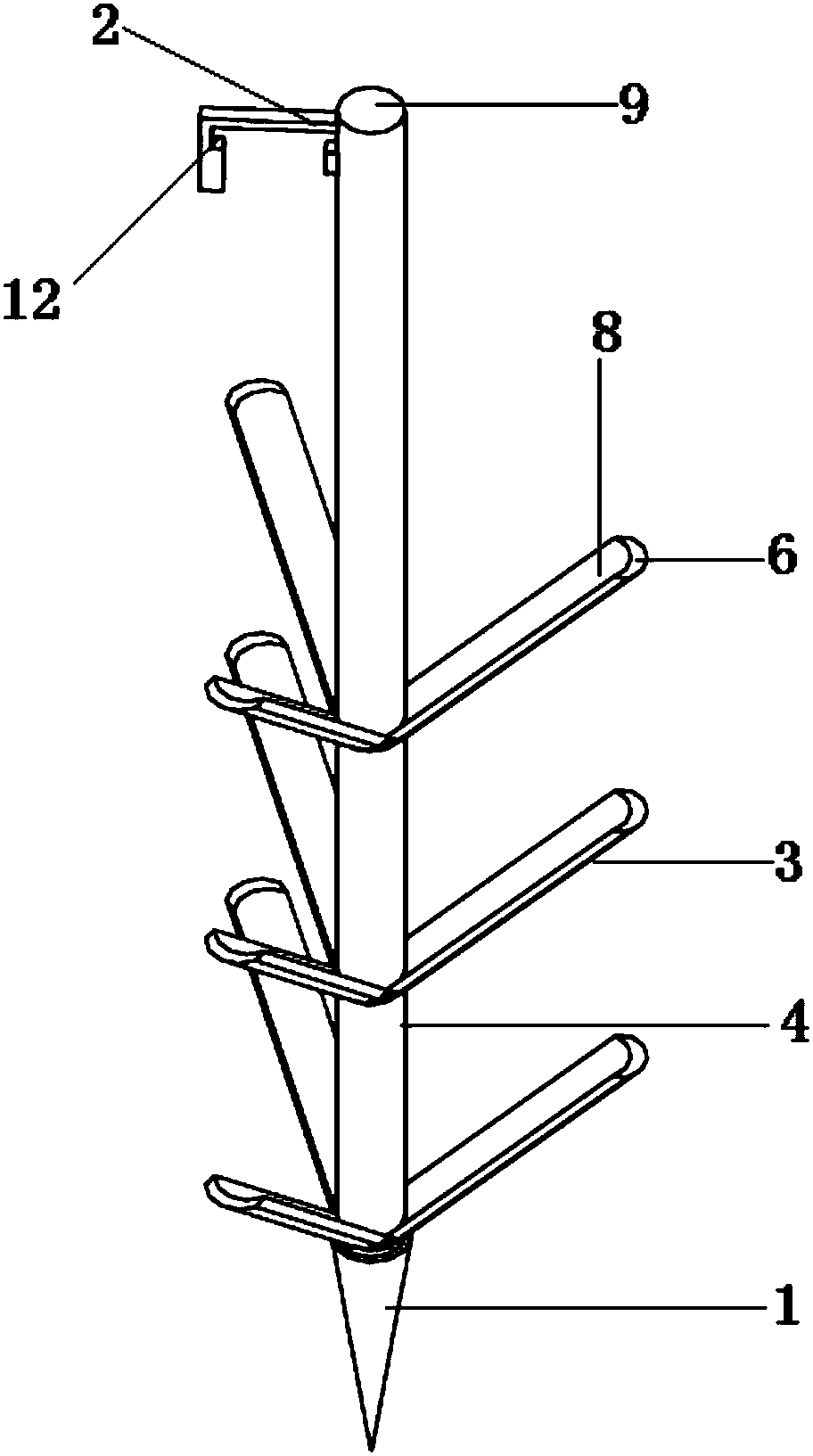

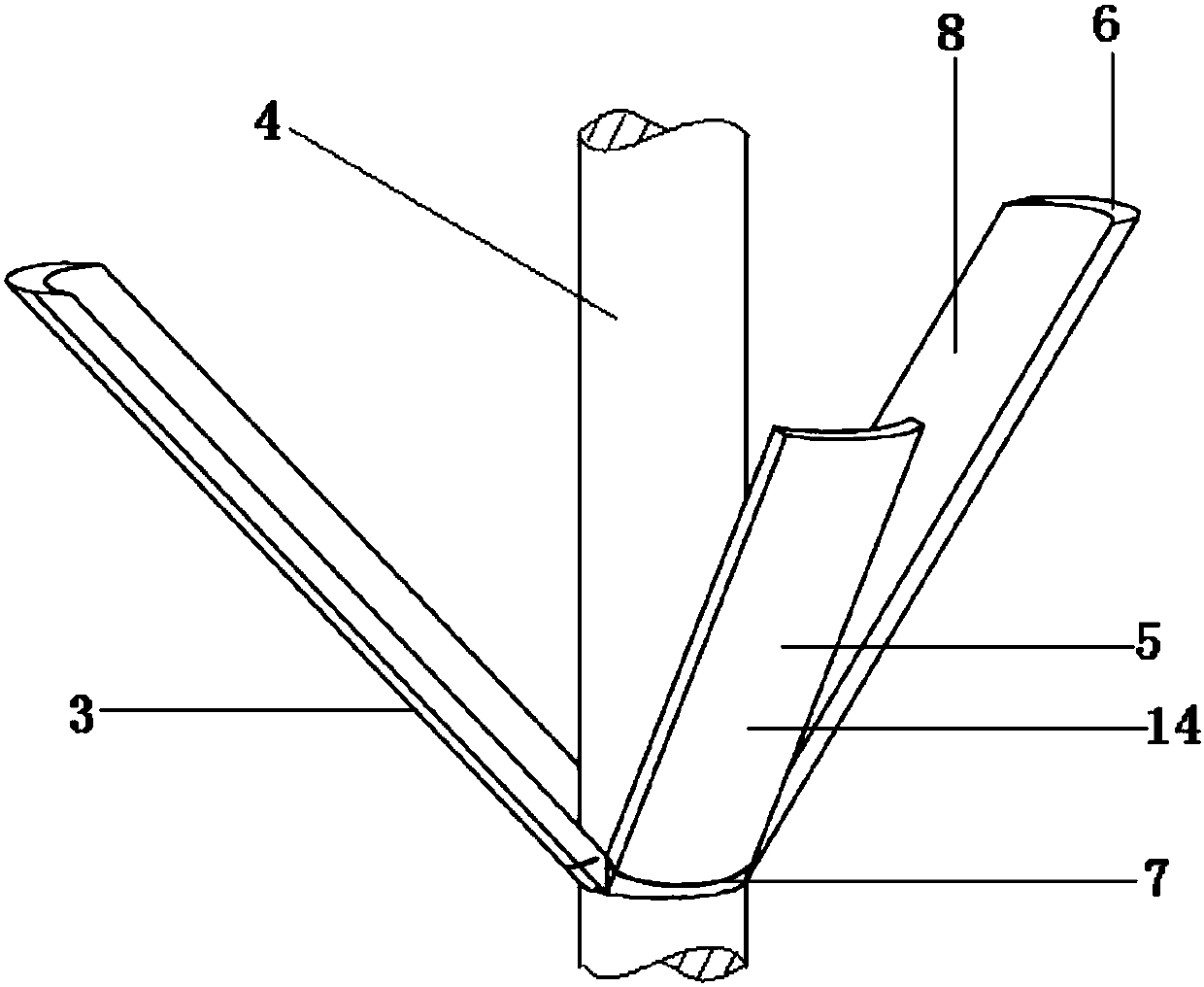

[0023] The integrated layering holder of the present invention, such as Figure 1 to Figure 4 As shown, it consists of a tip 1, a shaft and a buckle 2.

[0024] The lower end of the integrated bead holder is a rod tip 1, and the rod tip 1 is an inverted cone shape.

[0025] Above the tip 1 is a shaft, and a plurality of arch wings 3 are connected to the side of the shaft. The shaft of the shaft cylinder 4 and the shaft of the tip 1 are on the same straight line, and the thickness of the shaft cylinder 4 is smaller than the thickness of the conical bottom surface of the tip 1. The arch wing 3 is in the shape of an arch, and its lower end is connected with the shaft column 4, and the arch wing 3 allows the integrated bead holder to be fixed in the soil. When the integrated bead holder stands in the air, it is not affected by other external forces except gravity and supporting force. The axis of the shaft cylinder 4 intersects the generatrix extension line of the center of the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com