Semi-cylindrical branch pressing and fixing device

A semi-cylindrical and fixer technology, applied in layers and other directions, can solve problems such as: wood piles will be pulled up by the branches of the mother plant in rainy days, labor-intensive and time-consuming operation of the layering process, and affect the germination of buds on the branches, etc., to achieve shortening The effect of seedling production cycle, saving labor time and money, and reducing seedling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

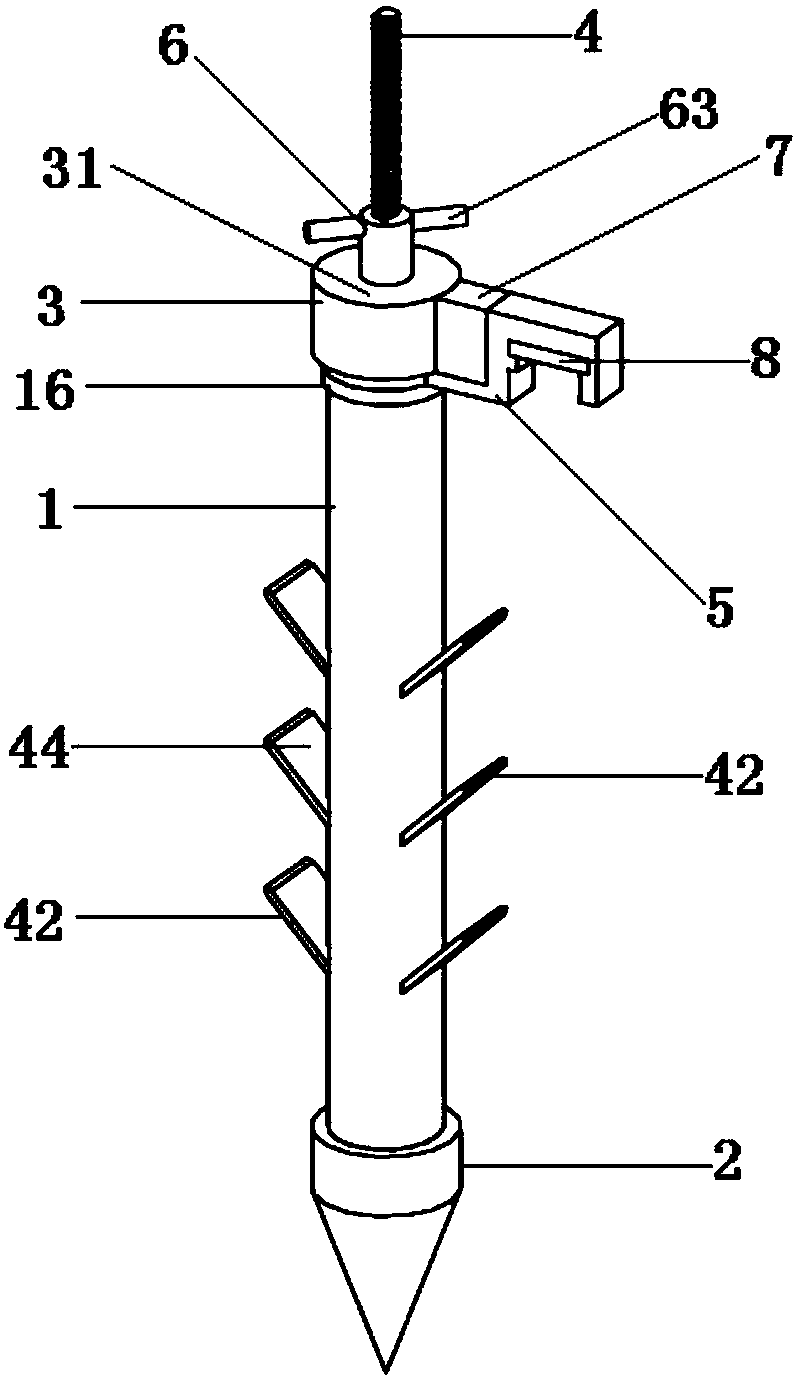

[0047] As another embodiment of the present invention, a groove 55 is provided below the pressing plate 51 of the band collar pressing plate 5, and a soft gasket 8 is arranged in the groove 55, and the soft gasket 8 can protect the branch bark of the mother plant.

[0048] As another embodiment of the present invention, the color of each part of the semi-cylindrical bead holder is yellow or red. That is, the parts of a fixer can all be yellow, or all red, or some can be yellow and some can be red. In this way, it is easy to be observed and found in the field, which is convenient for operation and improves efficiency.

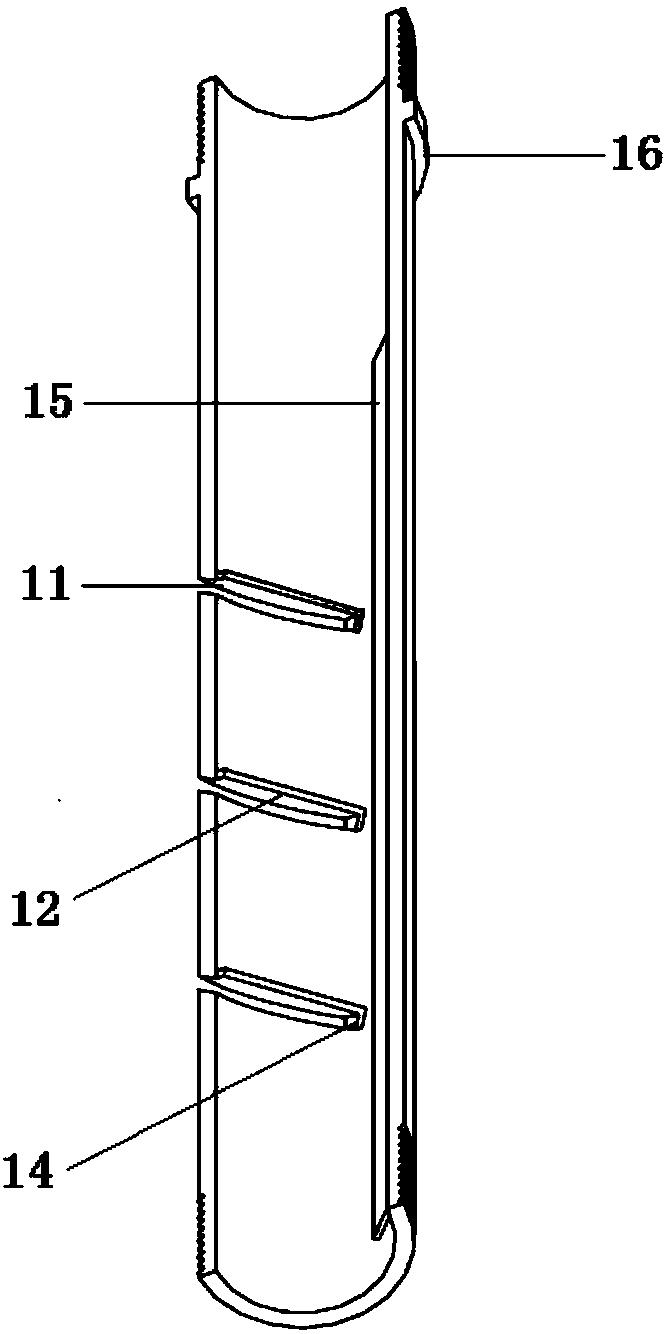

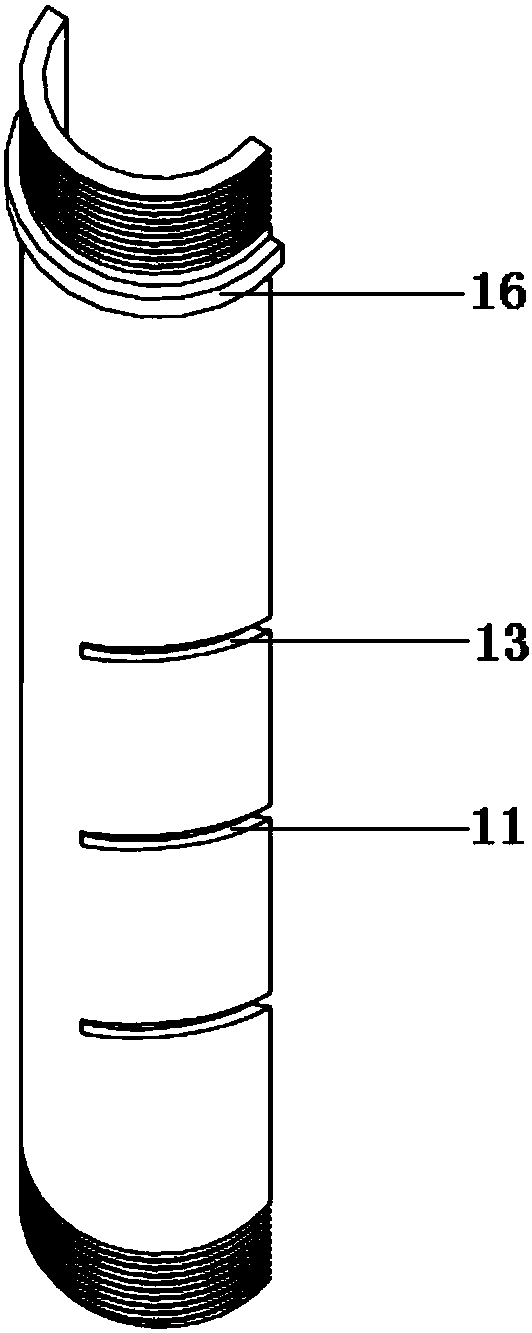

[0049] This fixer can be installed like this: connecting wing bar 4 is put in a half cylinder 1, allows a part of wing plate 42 to enter the half groove 11 of half cylinder 1, puts another half cylinder 1 together again, and allows another A part of the wing plate 42 enters the half groove 11 of the other half cylinder 1; the bobbin head 2 is installed on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com