Safely-lockable power supply device

An electric power supply and safety technology, applied in the direction of preventing contact with live contacts, coupling devices, two-part connection devices, etc., can solve problems such as potential safety hazards, unstable power supply connection, burning of electrical equipment, etc., to achieve safe and stable use. , The power supply stability is good, and the effect of avoiding electric shock accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

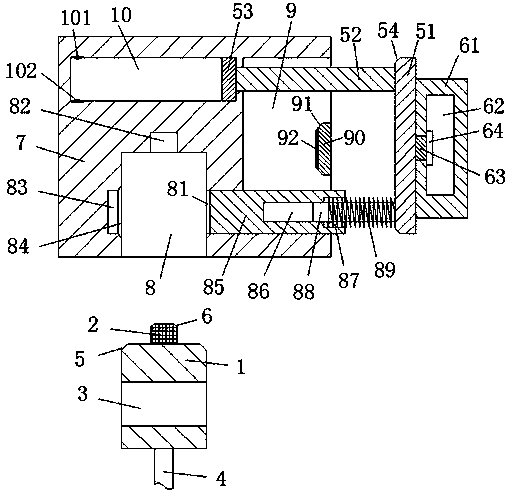

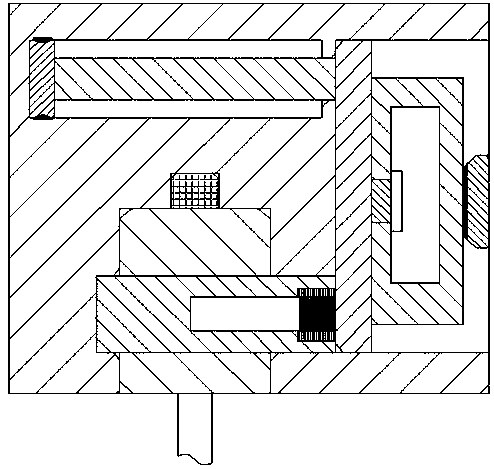

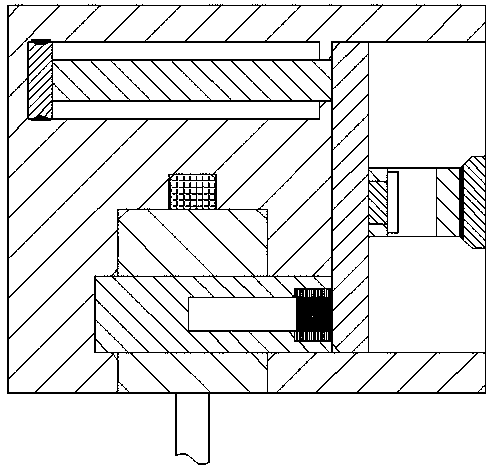

[0021] refer to Figure 1-5 A power supply device with locking safety shown includes a plug main body 1 connected to an electrical device by a cable 4 and a power supply base main body 7 for inserting the plug main body 1 into a mating connection. The top end of the plug main body 1 There is a plug 2 in the middle of the surface, the plug main body 1 is provided with a left and right through locking channel 3, the bottom end surface of the power supply seat main body 7 is provided with an access groove 8, and the right end surface of the power supply seat main body 7 is provided with a rotating handle Lock cavity 9, the main body of the power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com