Horizontal linear fatigue test machine

A fatigue testing machine, straight line technology, applied in the testing of mechanical components, testing of machine/structural components, using stable tension/pressure to test the strength of materials, etc., can solve the problems of increased cost and high test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

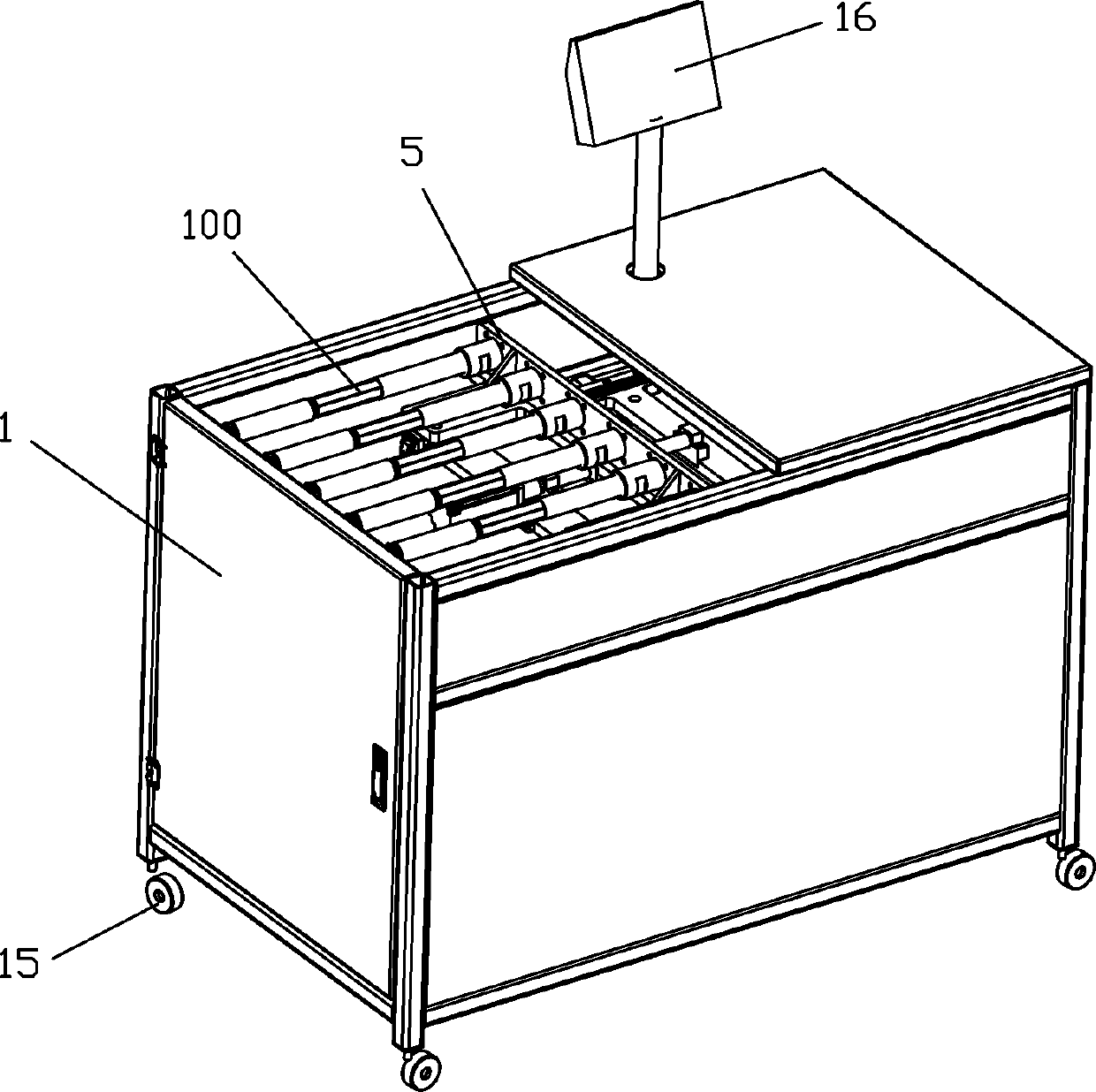

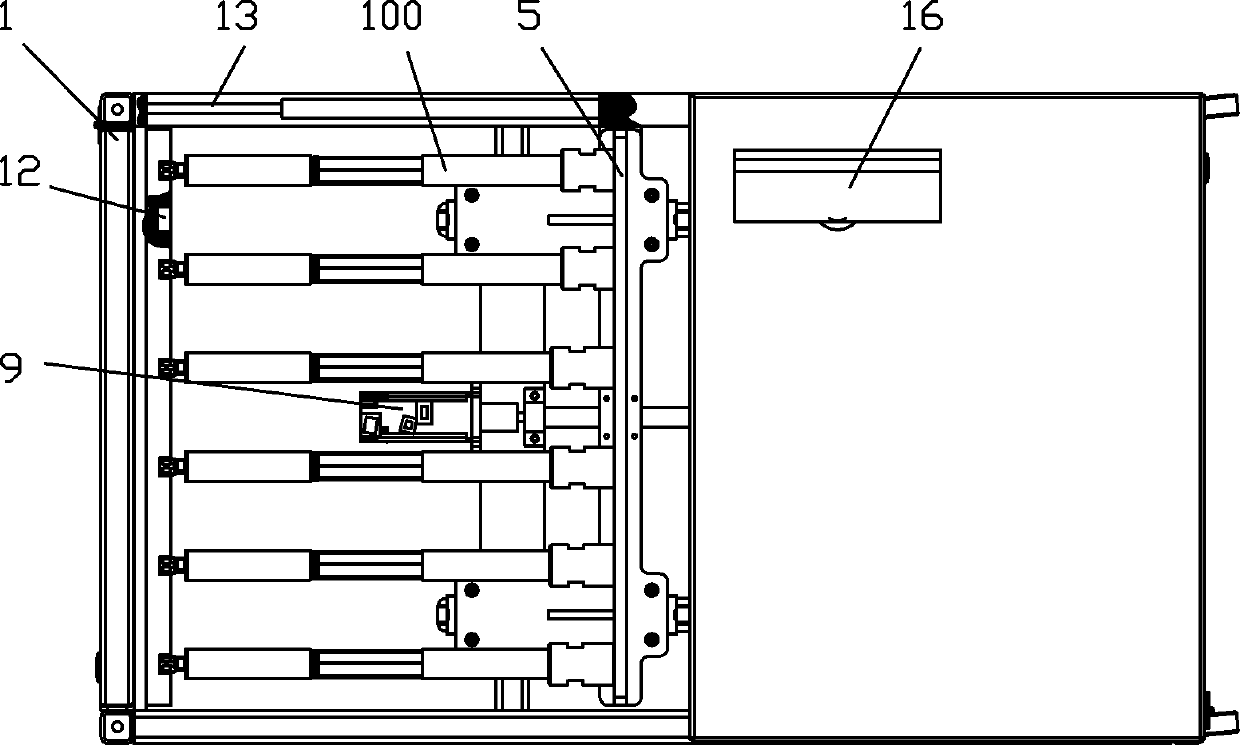

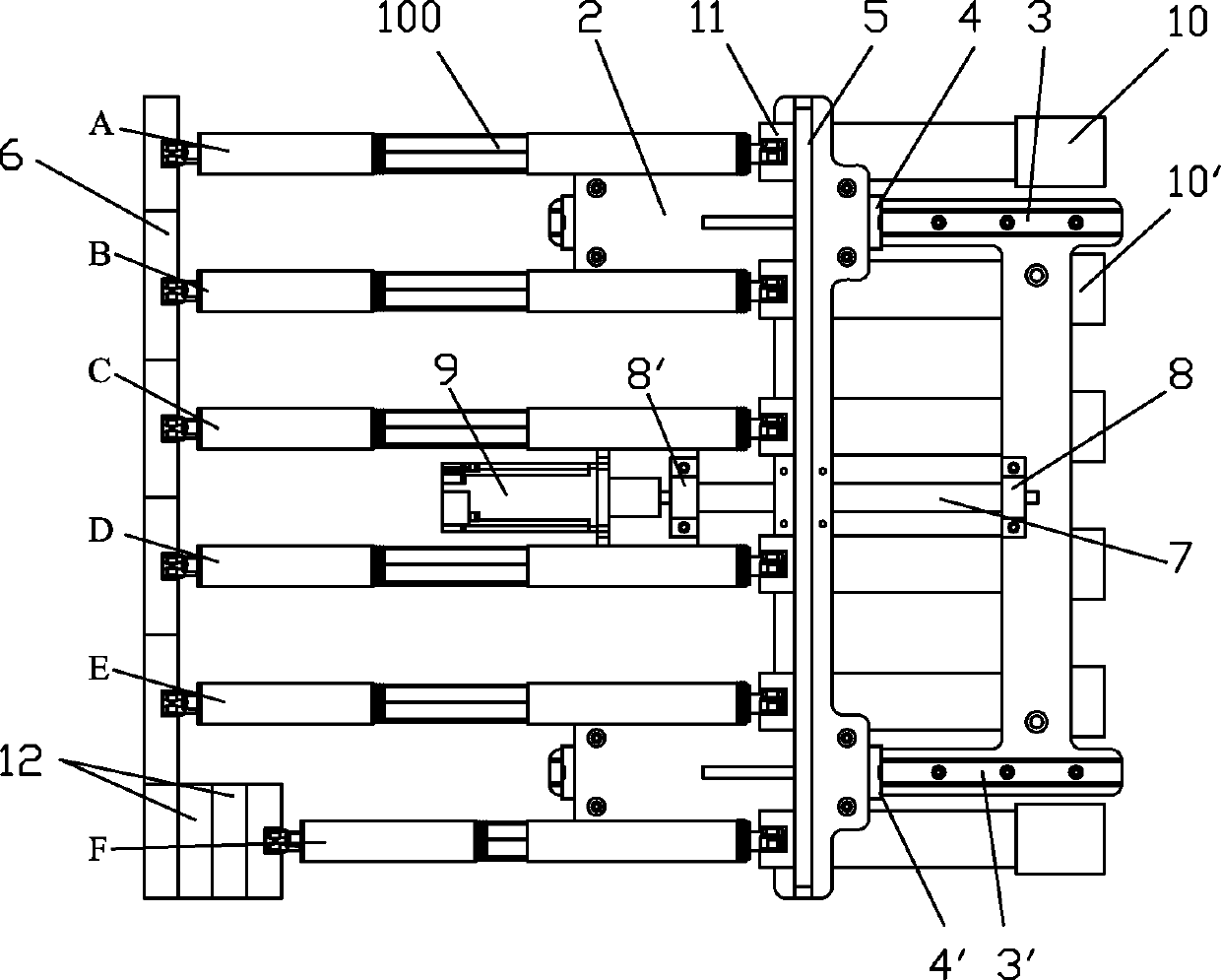

[0025] see Figure 1 ~ Figure 4 , a kind of horizontal linear fatigue testing machine of the present invention, it comprises,

[0026] Cabinet 1, the top surface is an openable structure;

[0027] The base plate 2 is arranged on the inner upper part of the cabinet 1, and the base plate 2 is a frame structure;

[0028] Two pairs of guide rails 3, 3' and sliders 4, 4', the two pairs of guide rails 3, 3' are respectively arranged on the upper end surfaces of the frame on both sides of the substrate 2;

[0029] The crossbeam 5 is connected to the upper end surface of the sliders 4 and 4' on both sides of its bottom surface. The crossbeam 5 is provided with several through holes at intervals along the length direction. In contrast, the inside of the cabinet 1 is provided with a plurality of electric struts 100 connectors. A ball-socket support plate 6 fixed to the ball-socket, the ball-socket support plate 6 is opposite to and parallel to the beam 5;

[0030] The screw rod 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com