Wire tensioning device control device

A control device and wire tightening technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as low operating efficiency, achieve the effects of improving efficiency, saving operating field space, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

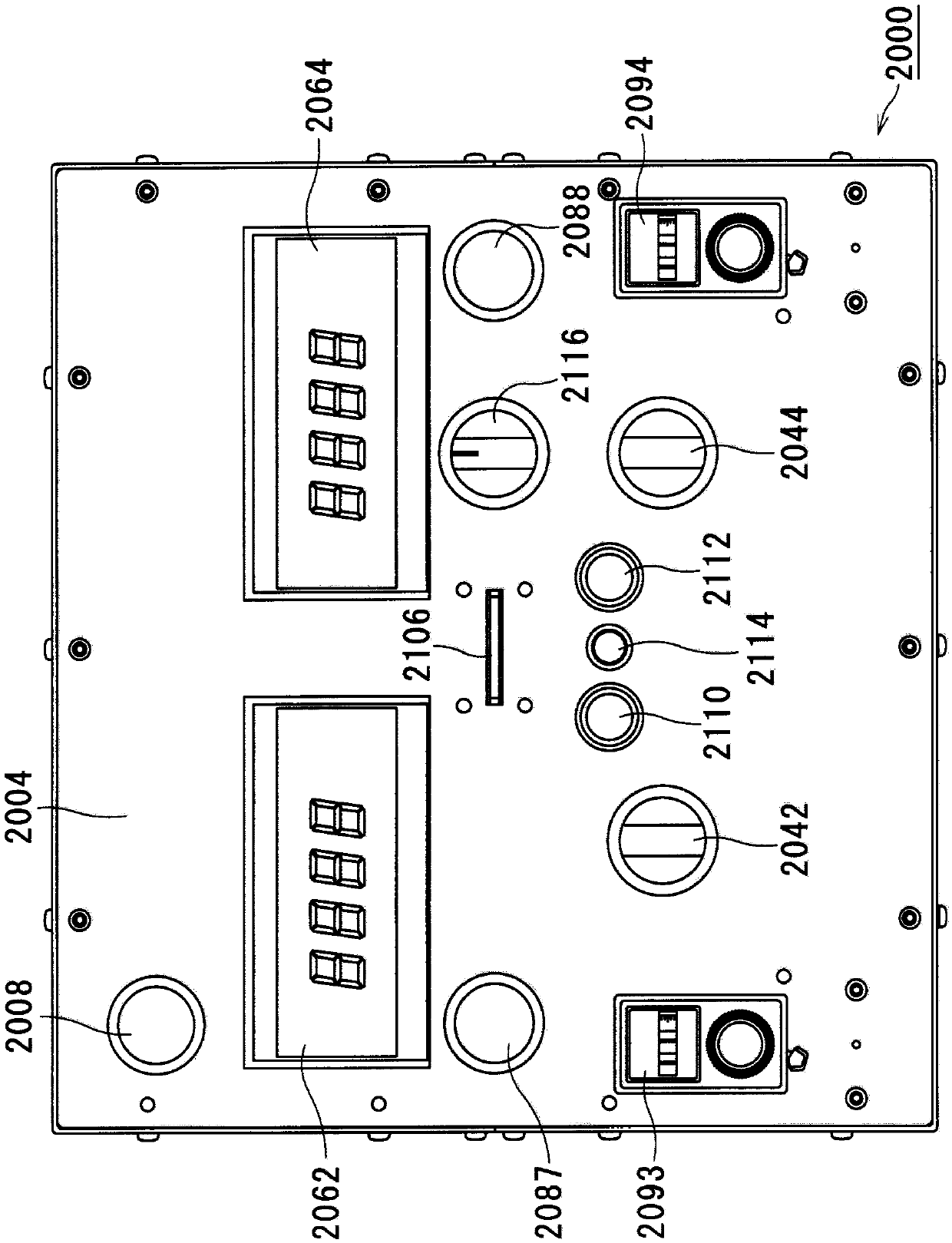

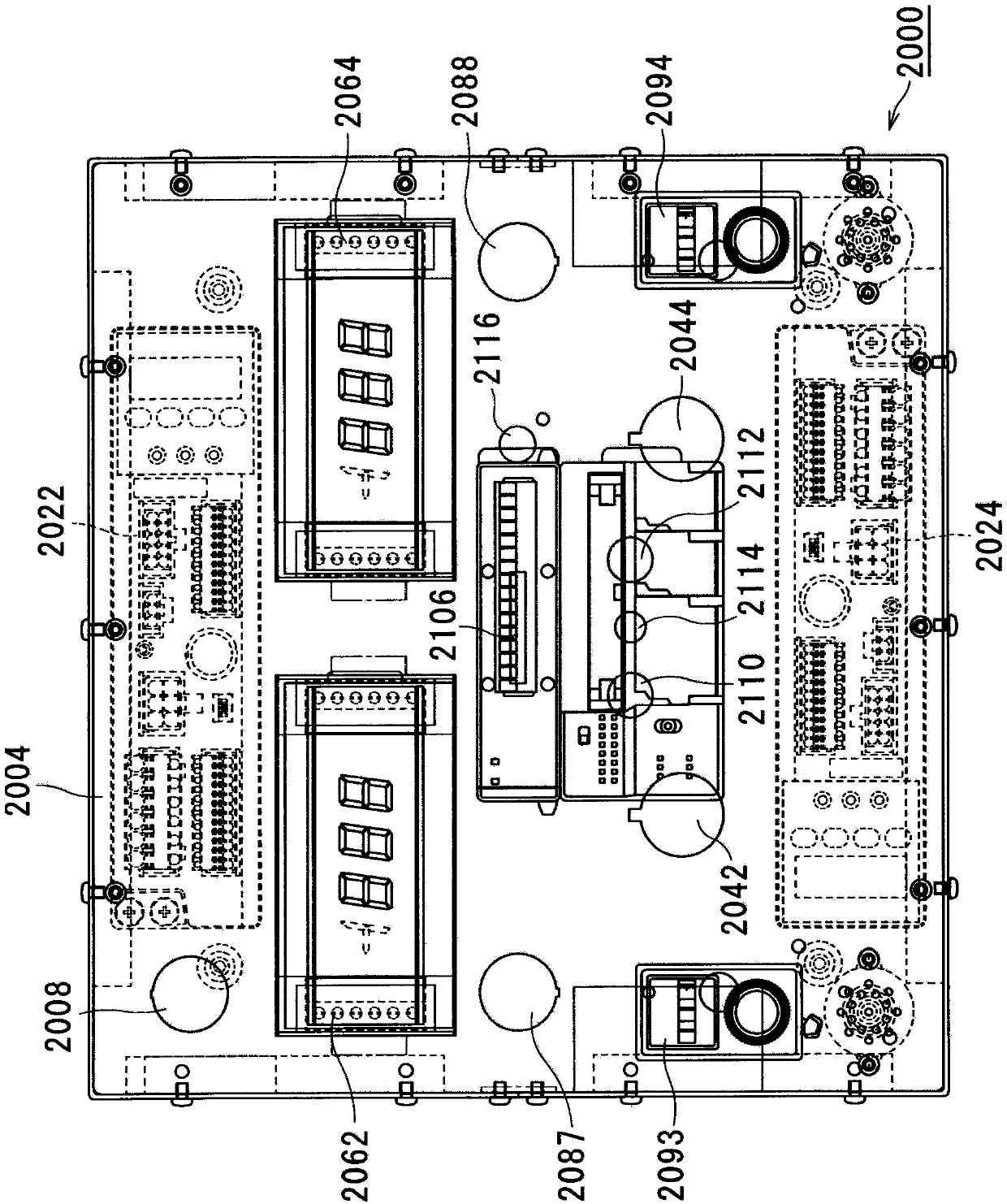

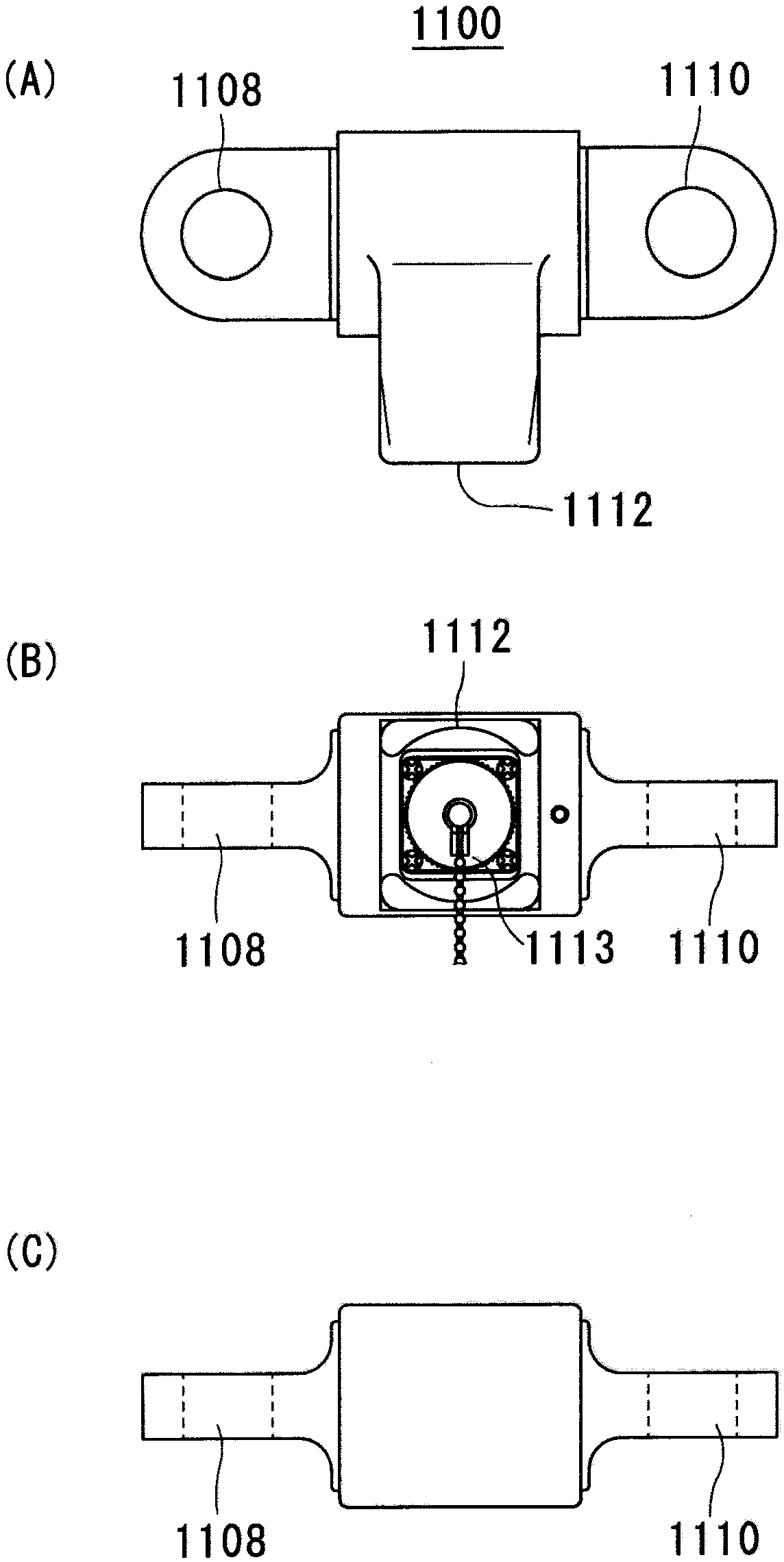

[0034] Before describing the control device of the thread tensioning device of the present invention, at first, refer to Figure 5 and Figure 6 One embodiment of the thread tensioning device controlled by the control device of the thread tensioning device of the present invention will be described. Also, subsequently, refer to image 3 An embodiment of a tension gauge (load sensor) that measures the tension of an electric wire or the like and transmits an electric signal value corresponding to the tension to the control device of the wire tensioning device of the present invention will be described.

[0035] (Structure of the tensioning device)

[0036] Figure 5 It is an exploded perspective view showing one embodiment of the thread tensioning device controlled by the control device of the thread tensioning device of the present invention. in addition, Figure 6 It is a front sectional view of one embodiment of the thread tensioning device controlled by the control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com