A comb-tooth plate stacker

A stacker and comb technology, applied in the field of comb-type plate stackers, can solve the problems of low production efficiency, limited service area, low adaptability to the variety of loaded plate specifications, etc., and achieve low cost and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

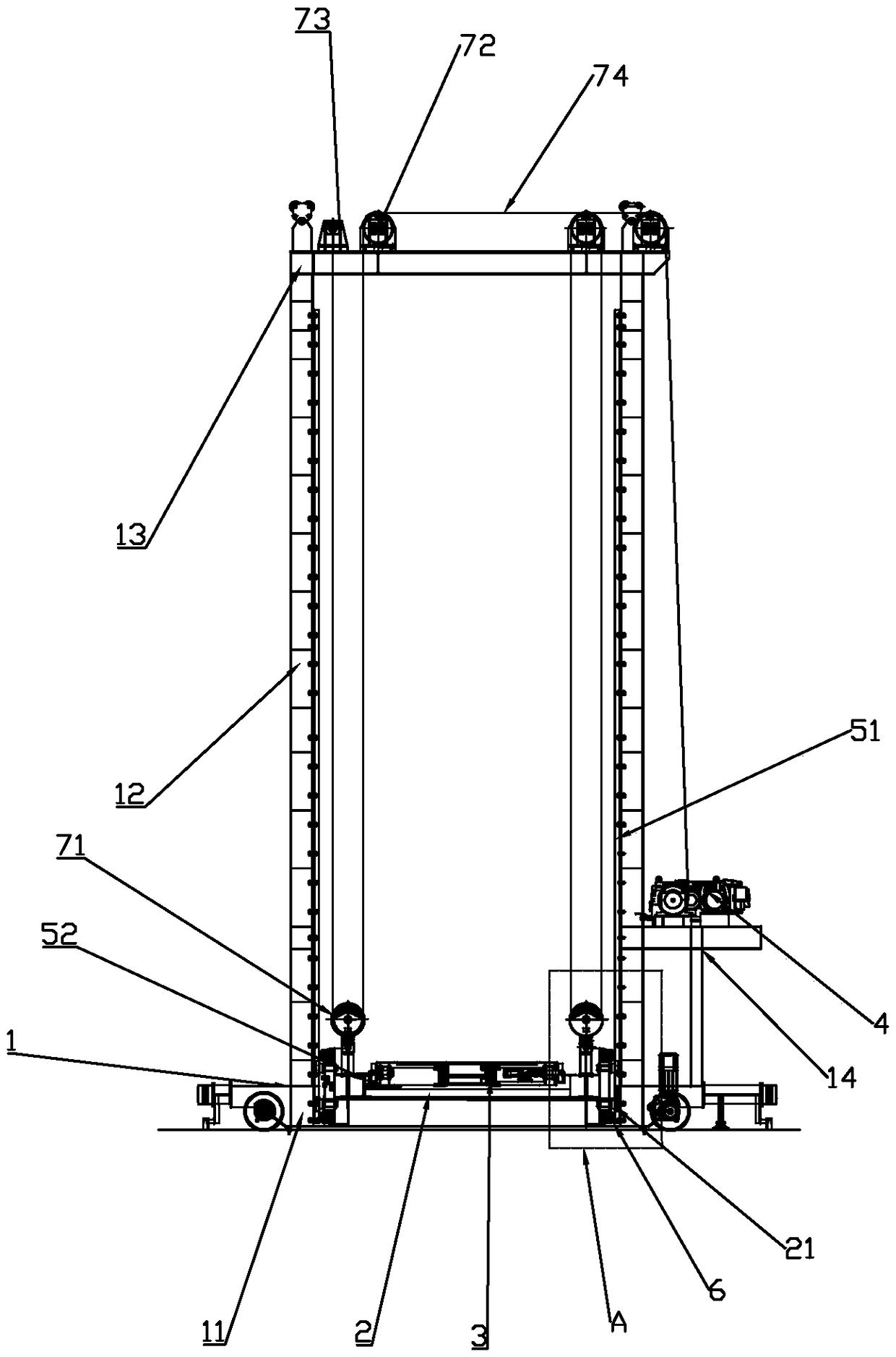

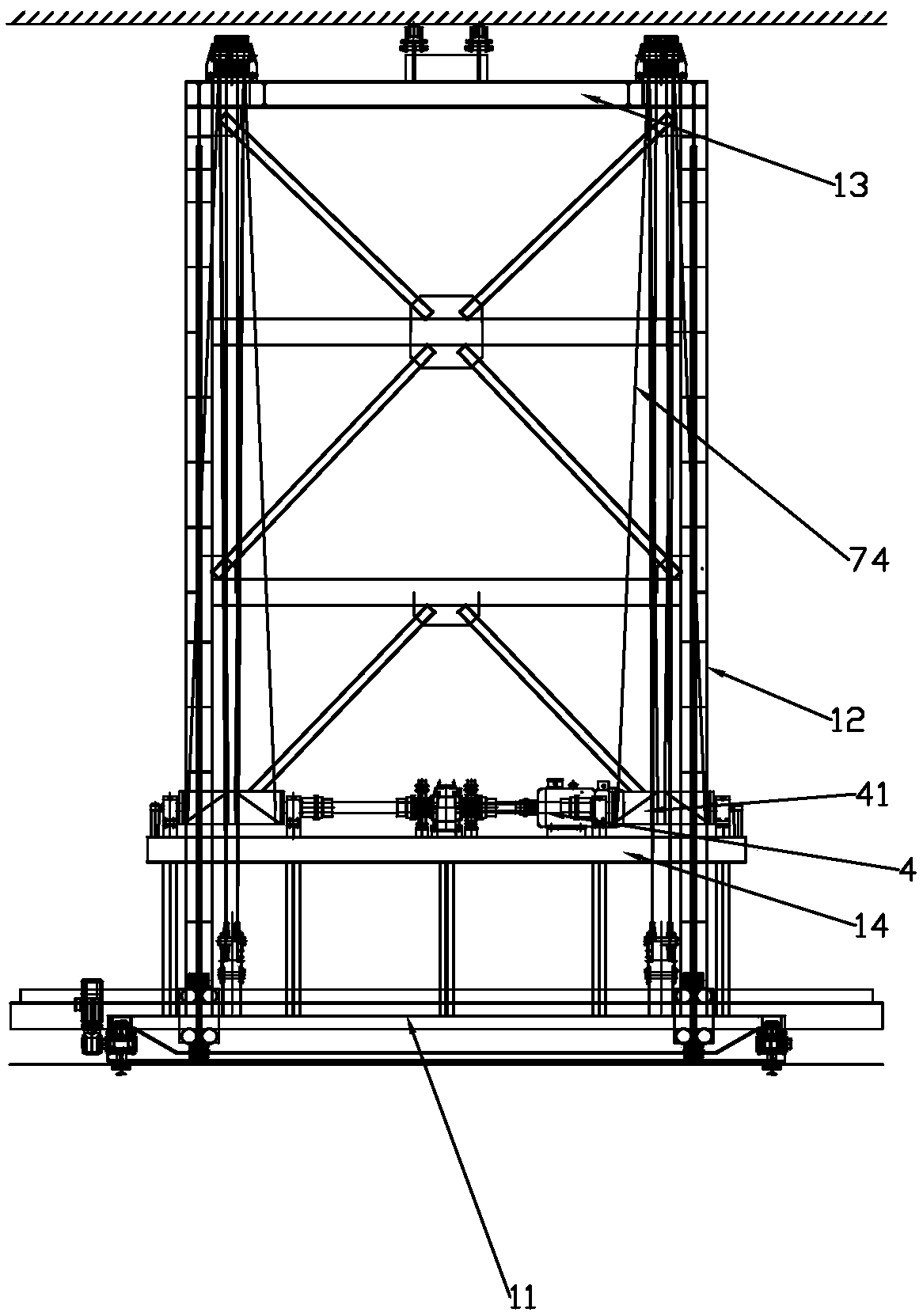

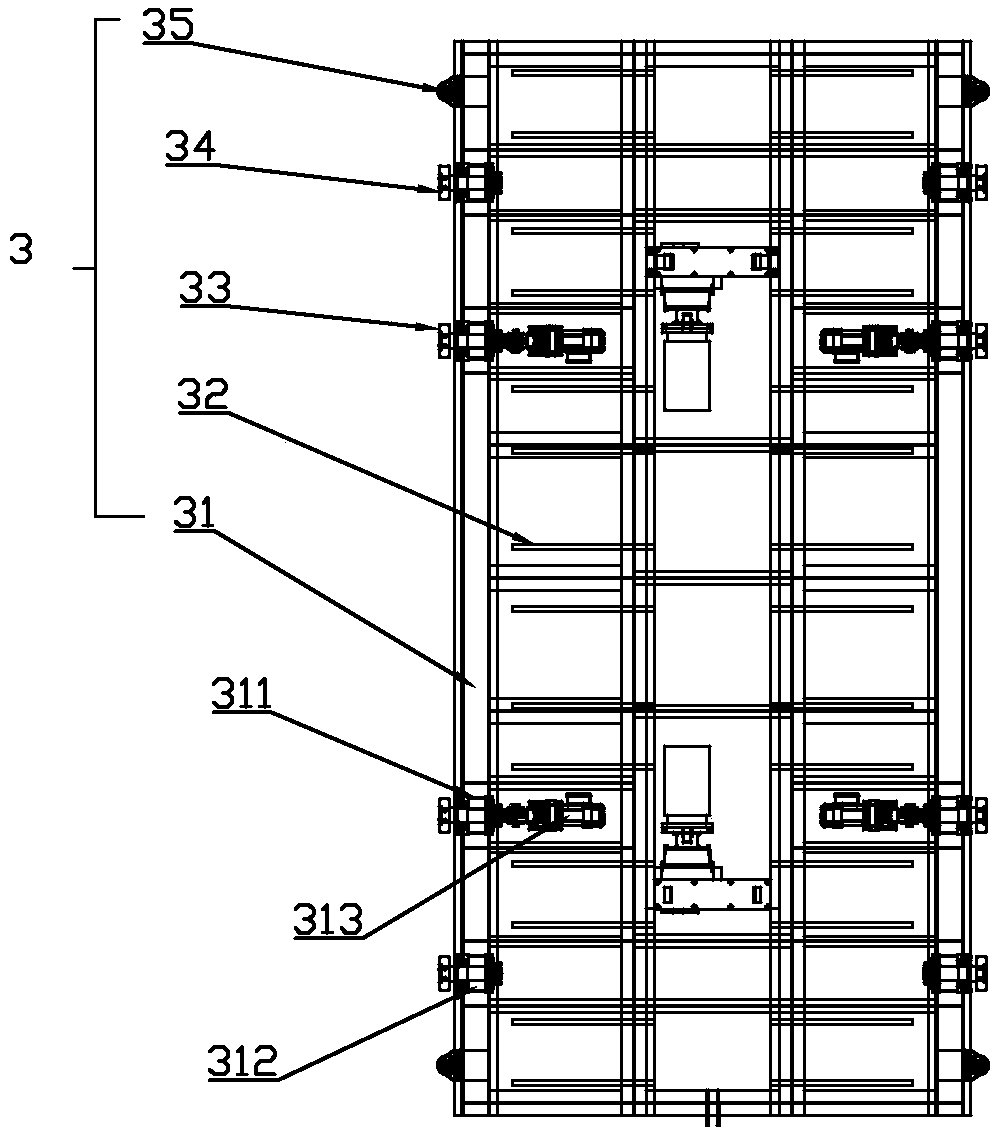

[0037] Such as Figure 1 to Figure 8 As shown, a comb-tooth plate stacker includes a main structure 1, a lifting trolley 2, a transport trolley 3 and a lifting mechanism 4,

[0038] The main structure 1 includes a bottom plate 11, a column 12, a top plate 13 and a support frame 14. The lower ends of the four columns 12 are fixed to the upper end of the bottom plate 11 in a rectangular shape, and the inside of the columns 12 are fixedly connected to the first guide rail 51 by bolts. The lower end of the top plate 13 is fixed to the upper end of the column 12, the lower end of the support frame 14 is fixed to the right side of the bottom plate 11, and the left end of the support frame 14 is fixed to the bottom of the column 12 on the right side;

[0039] The left and right ends of the lifting trolley 2 are fixedly provided with vertically symmetrical first guide wheels 6 that are rollingly connected with the first guide rail 51, and the vertically symmetrical first guide wheels ...

Embodiment 2

[0058] Such as Figure 9 to Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that it also includes four sets of operating mechanisms 8 fixed to the lower end of the bottom plate 11 in a rectangular shape, and the operating mechanisms 8 include a first drive motor 81, an intersecting axis gearbox 82 and a bottom guide wheel 83, the bottom guide wheel 83 is connected with the first drive motor 81 through the intersecting shaft gearbox 82.

[0059] The running mechanism 8 is rollingly connected with the bottom guide rail 101 on the ground through the bottom guide wheel 83, so that the comb-tooth plate stacker can move in the warehouse.

[0060] Further, in the above technical solution, the top guide device 9 is symmetrically arranged at the left and right ends of the middle part of the top plate 13, and the top guide device 9 includes a connecting support 91, a guide wheel connecting rod 92 and a top guide wheel 93. The lower end of the support 91 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com