Vertical axis-type hydroelectric power generating device and vertical axis-type hydroelectric power generating unit

A technology of hydroelectric power generation device and vertical axis, which is applied in the direction of hydropower generation, water wheel, machine/engine, etc. It can solve the problems of hindering popularization, huge initial cost and maintenance cost, economic rationality, maintenance cost of dust removal device, etc., and achieves the goal of setting Effects of cost suppression and sufficient output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, preferred embodiments for carrying out the present invention will be described using the drawings. It should be noted that the following embodiments are not intended to limit the invention of each technical solution, and combinations of features described in the embodiments are not necessarily essential to the solution means of the invention.

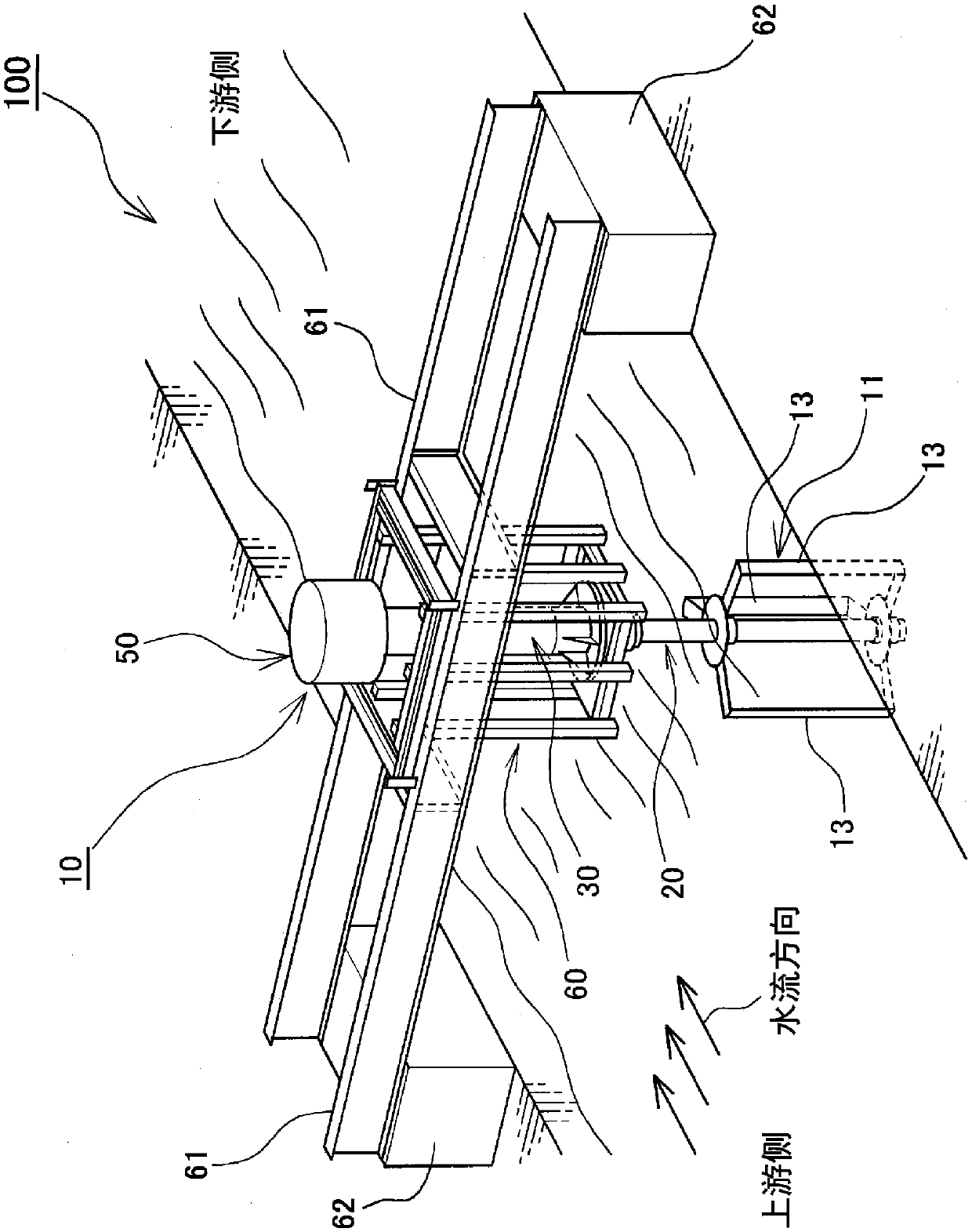

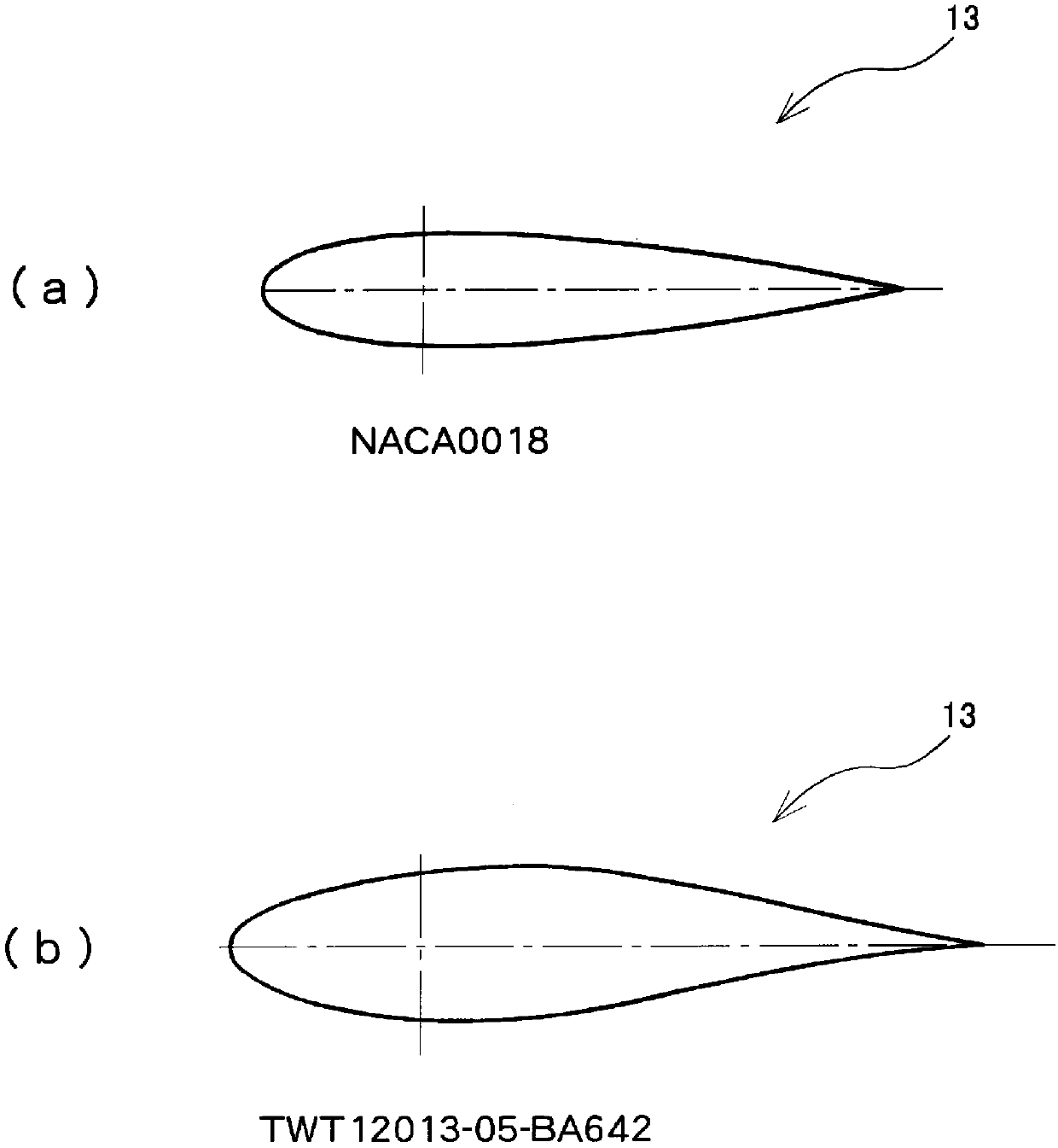

[0031] First, an example of the overall configuration of the vertical axis type hydroelectric power generation unit 100 according to the present embodiment will be described. here, figure 1 It is an external perspective view showing the overall configuration of the vertical axis type hydroelectric power generation unit according to the present embodiment, figure 2 It is a figure which exemplifies the shape of an airfoil applicable to the vertical-axis hydroelectric power generation apparatus which concerns on this embodiment.

[0032] The vertical-axis hydroelectric power generation device 10 according to the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com