Water-stop belt winding machine

A technology of waterstop and winder, applied in the field of waterproof construction, can solve the problems of easy pollution of waterstop, inadequate protection of finished products, distortion and deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated below by specific examples.

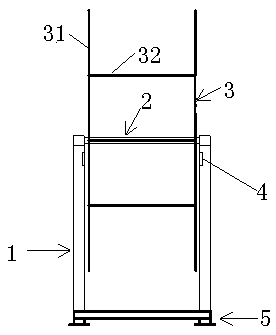

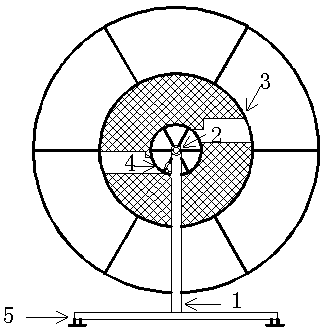

[0018] like figure 1 , figure 2 As shown, a waterstop winding machine includes a base frame 1, a rotating shaft 2 and a winding drum 3; the winding drum 3 is rotatably arranged on the base frame 1 through the rotating shaft 2, wherein the winding drum 3 The metal ring 31 is arranged on the side and a reinforcing rib is arranged between the winding drum 3 and the metal ring 31; the winding drum 3 includes two end plates and a plurality of connecting rods 32 connecting the two end plates; Into the gap between the connecting rods 32 and rotate the reel 3 to achieve the purpose of rewinding the waterstop.

[0019] The waterstop winding machine also includes a limit ring 4 and a limit rod, and the limit rings are respectively arranged on the two end plates of the reel, and the limit ring is inserted into the two limit holes. The position bar realizes the purpose of limiting the rotation of the ree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com