Annular track crane

A technology of circular track and crane, which is applied in the direction of crane, trolley crane, traveling mechanism, etc., can solve the problems of increased wear and tear of horizontal wheel, potential safety hazards, and increased gap between horizontal wheel and circular track, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

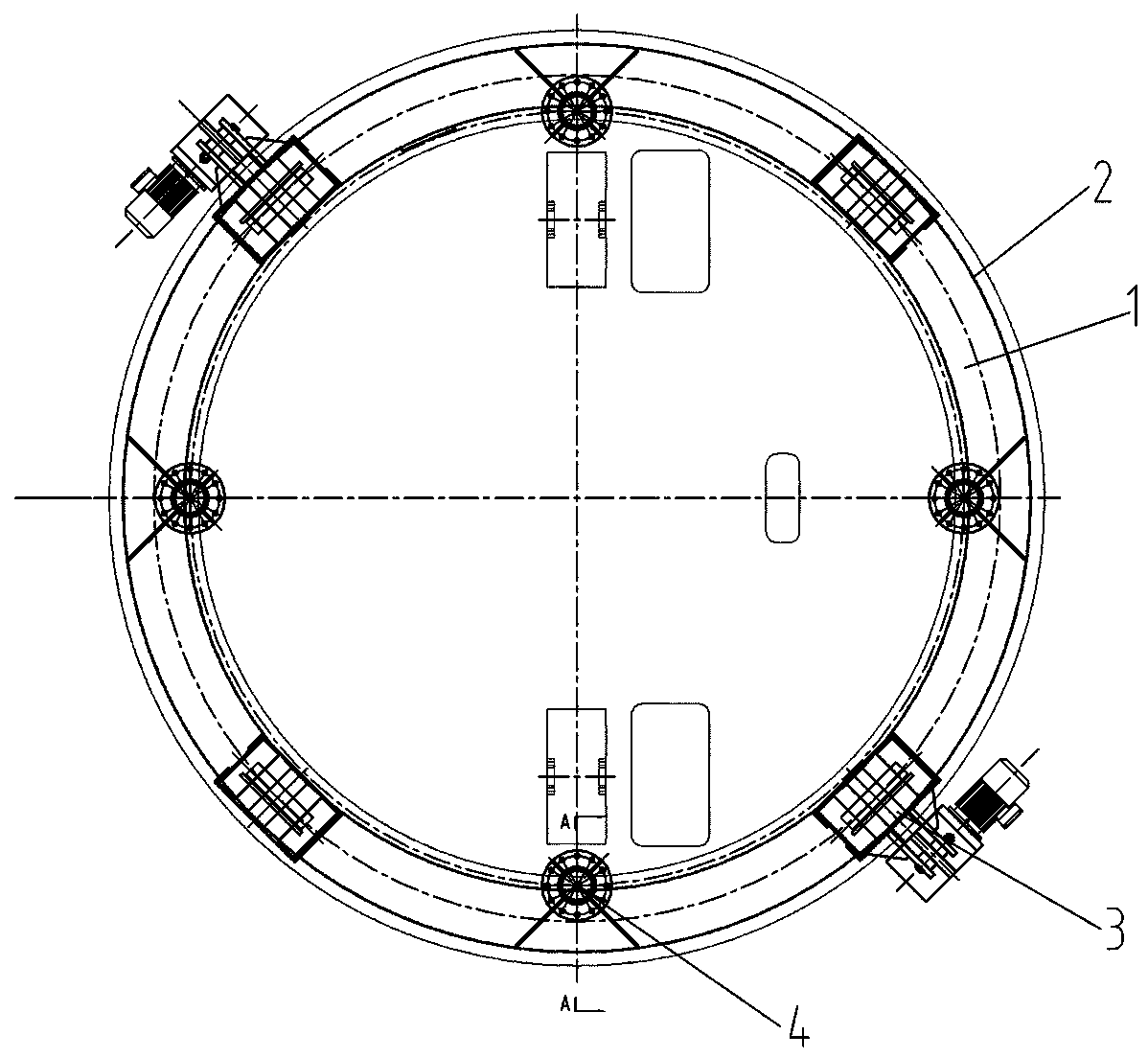

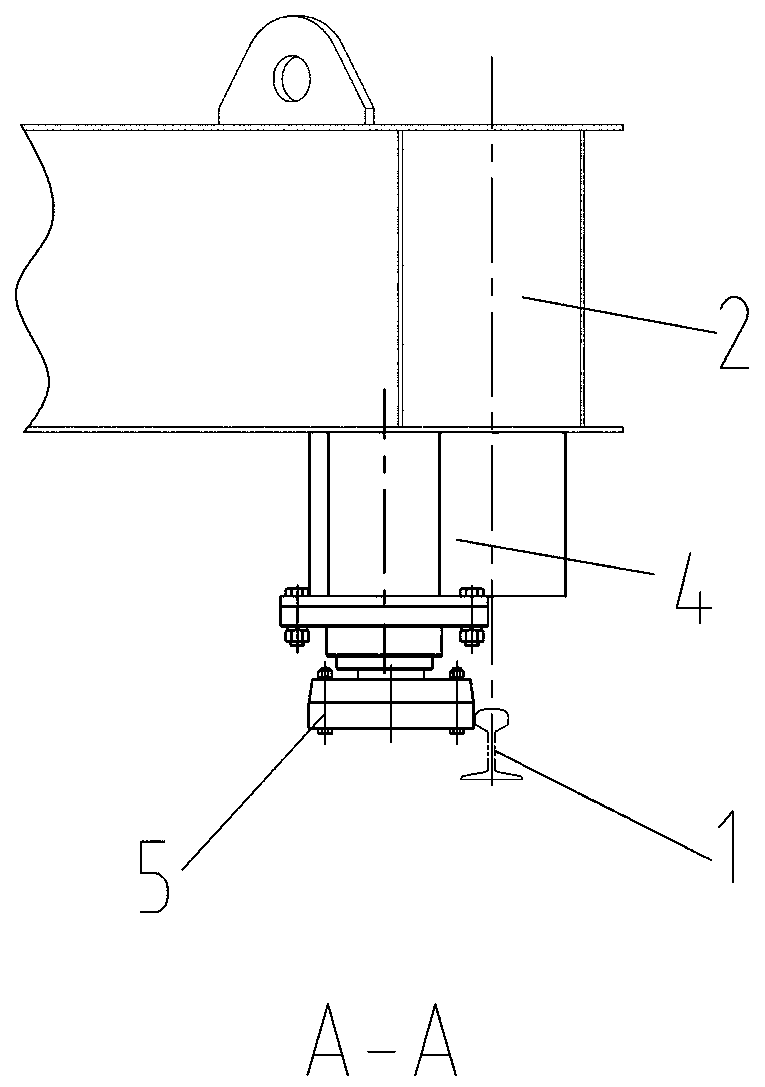

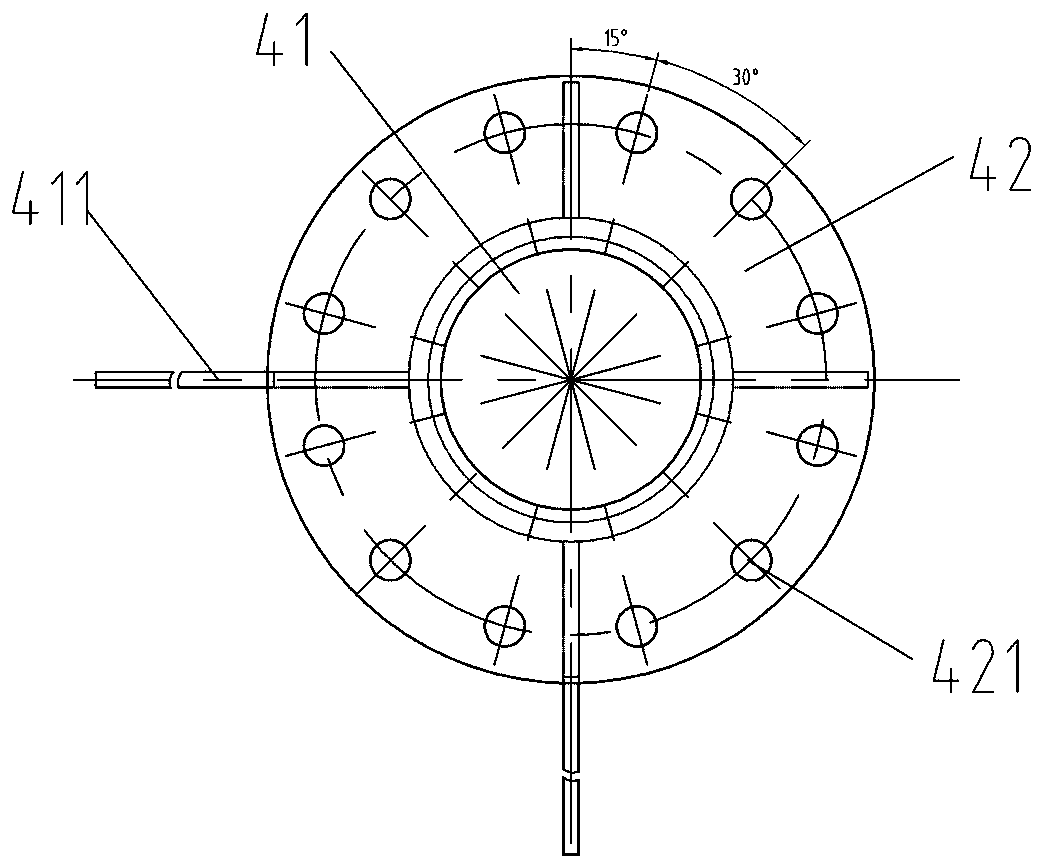

[0018] Specific embodiment one of the ring track crane of the present invention, as Figure 1 to Figure 4 As shown, it includes a ring track 1, a ring frame 2 and a lifting trolley 3, the ring frame 2 is compatible with the ring track 1, the lifting trolley 3 is fixedly connected with the ring frame 2 and can run along the ring track 1, the ring The vehicle frame 2 is connected with the horizontal wheel group 5 through the horizontal wheel group bracket 4. The horizontal wheel group bracket 4 includes a connecting part 41 and a bracket flange 42. The connecting part 41 is fixed on the ring frame 2, and the connecting part 41 and the bracket flange 42 Rotationally connected, the horizontal wheel set 5 includes a rotating shaft 51, a horizontal wheel 52 and a connecting flange 53, the lower end of the rotating shaft 51 is provided with a shaft shoulder 521, and the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com