Anchor stock mechanical response test device under dynamic and static combined load and using method thereof

A technology of combined load and testing device, which is applied in the direction of measuring device, testing material strength by applying repetitive force/pulsation force, testing material strength by applying stable tension/compression, etc., which can solve the weight, height and swing of the hammer The hammer angle range is limited, the size of the impact energy is limited, and the test results are difficult to provide accurate basis for the site, etc., to overcome the limitations of the test, the test results are stable, and the test results are accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

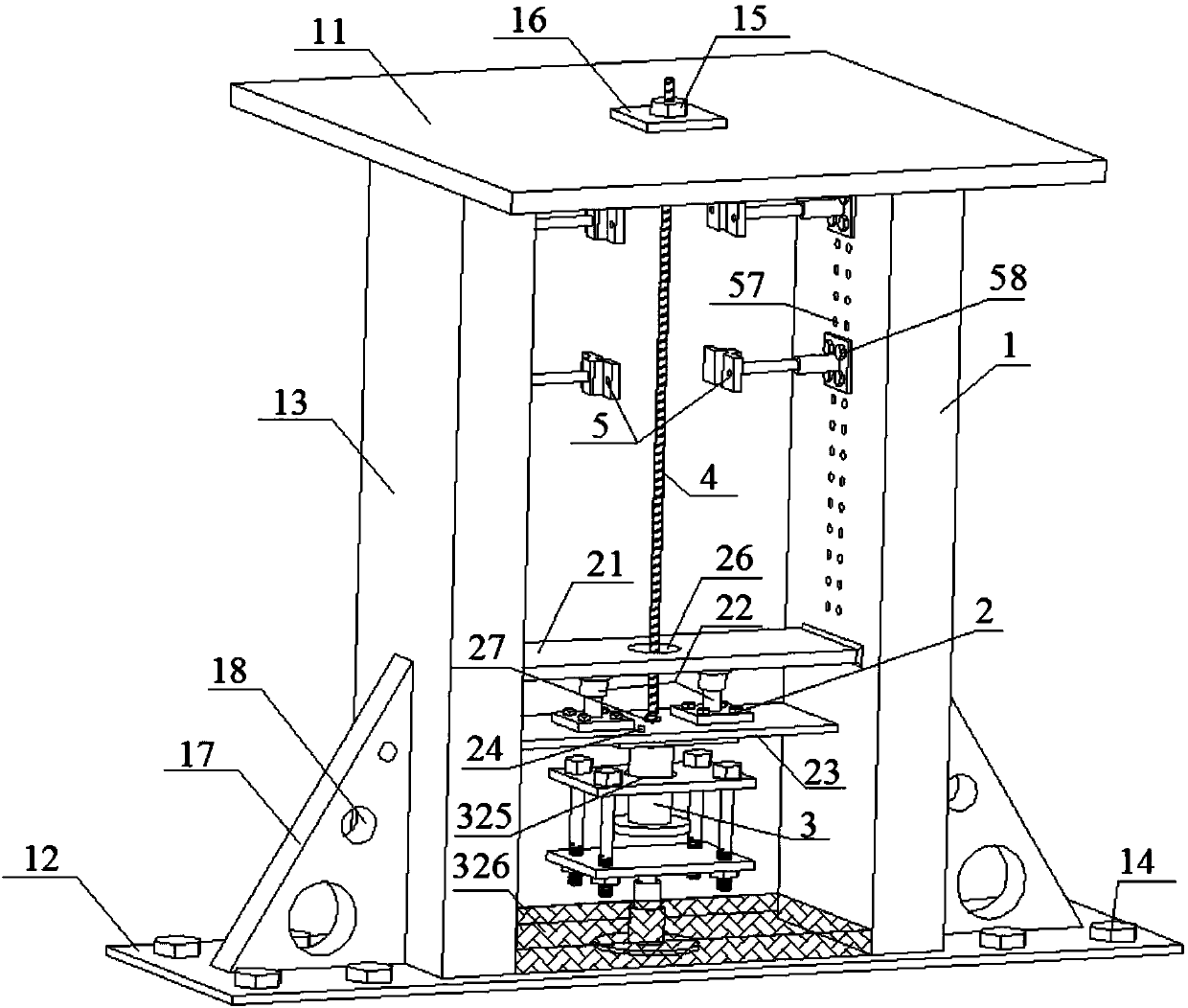

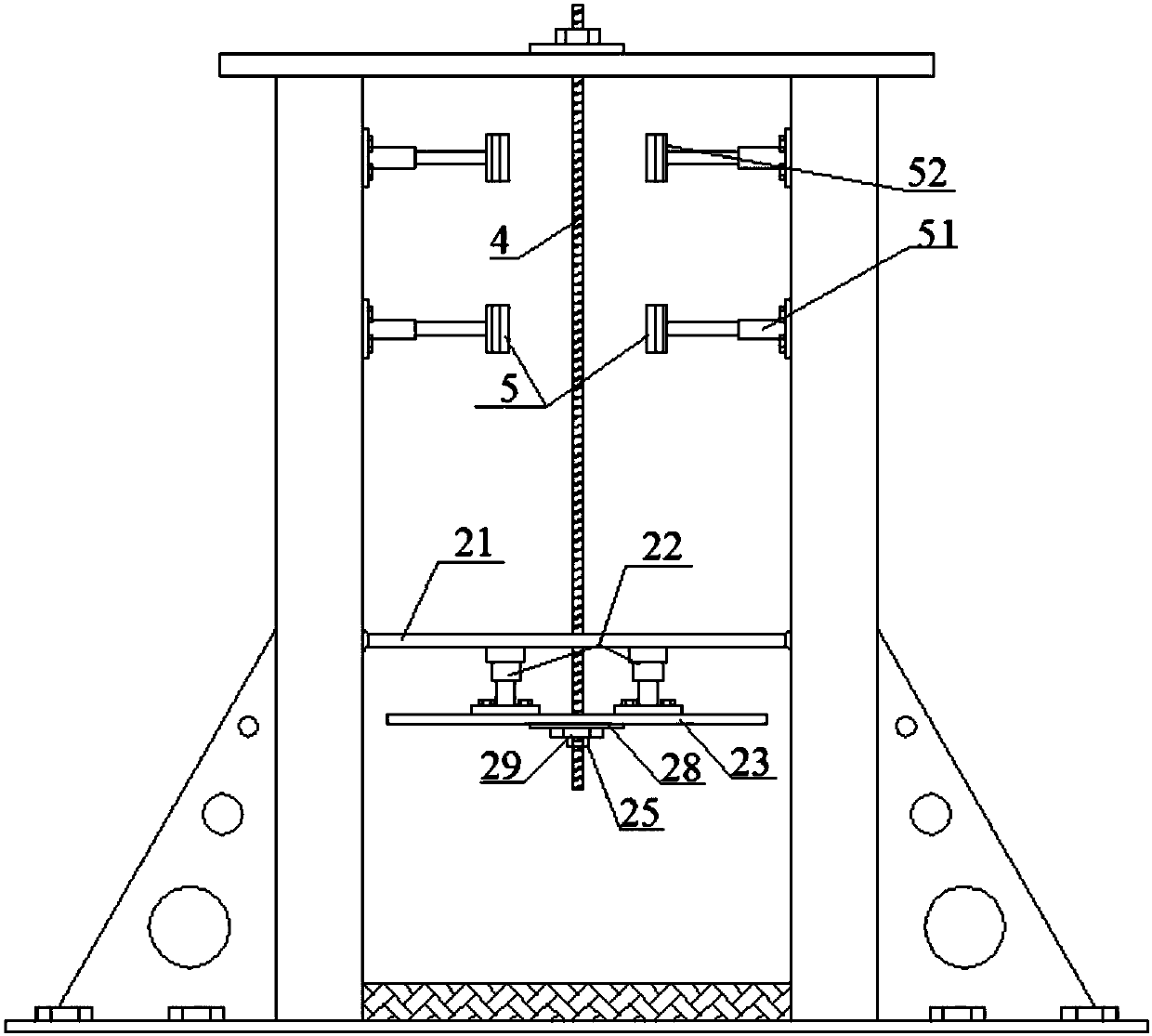

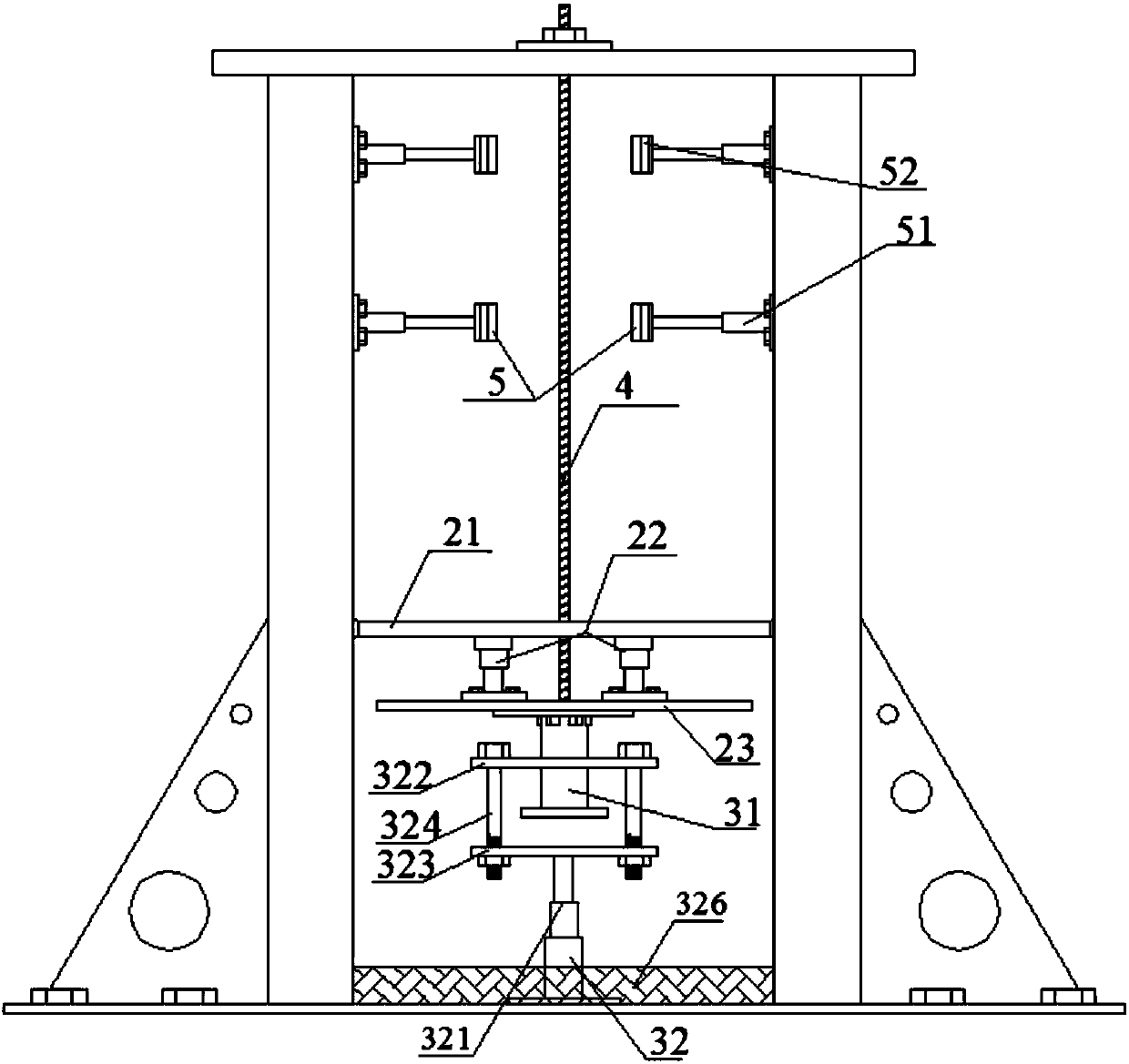

[0053] refer to Figure 1-3 As shown, the bolt testing device under dynamic and static combined loads of the present invention includes a vertical frame 1, a static load loading mechanism 2 and a dynamic loading mechanism 3, and the inside of the vertical frame 1 is provided with a bolt 4 to be tested, The upper end of the anchor rod 4 to be tested is fixedly connected to the top of the vertical frame 1, and its lower end extends vertically downward. connection, the static load loading mechanism 2 is used to apply static load to the anchor rod 4 to be tested, and the dynamic load loading mechanism 3 is arranged below the static load loading mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com