Retention-type rear cover separation device capable of braking and buffering based on large-impulse collision

A separation device and tail cover technology, which can be used in projectiles, self-propelled bombs, offensive equipment, etc., can solve the problems of complicated separation devices, and achieve the effects of increasing separation reliability, improving buffer efficiency, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

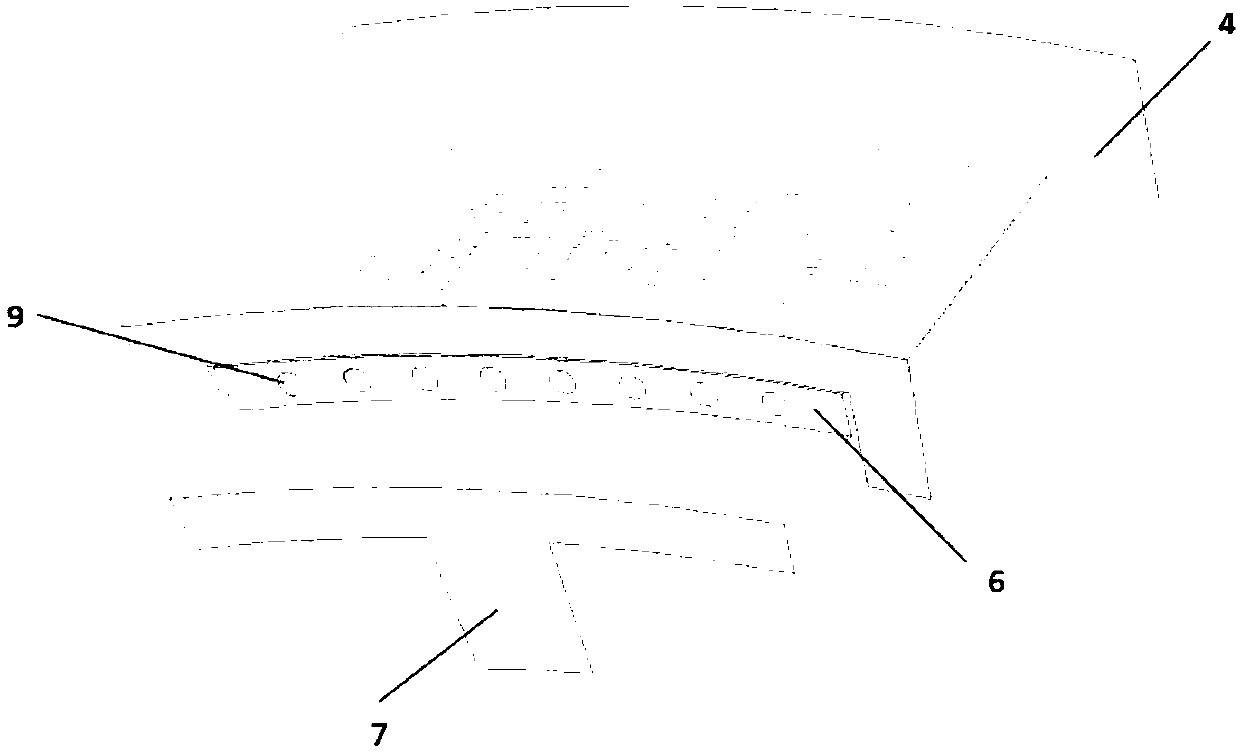

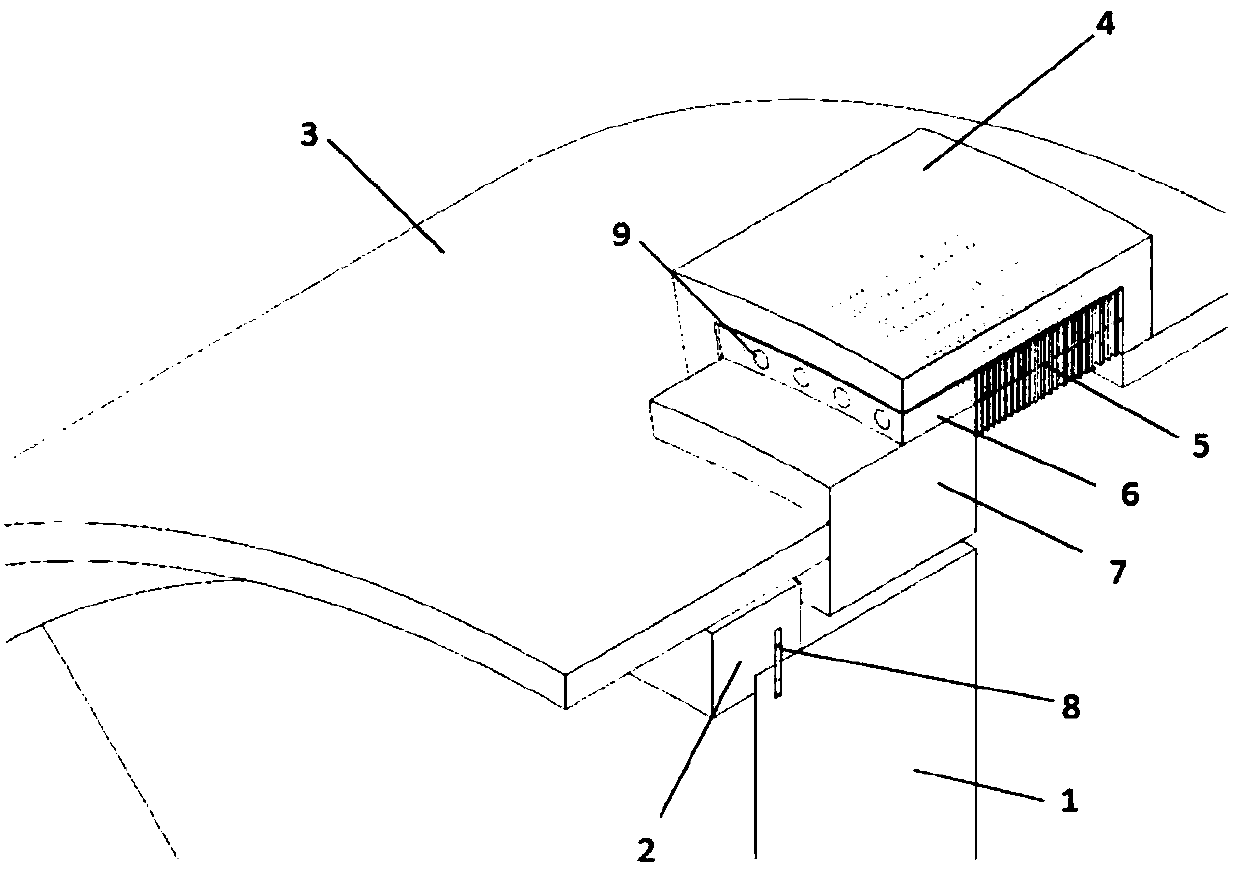

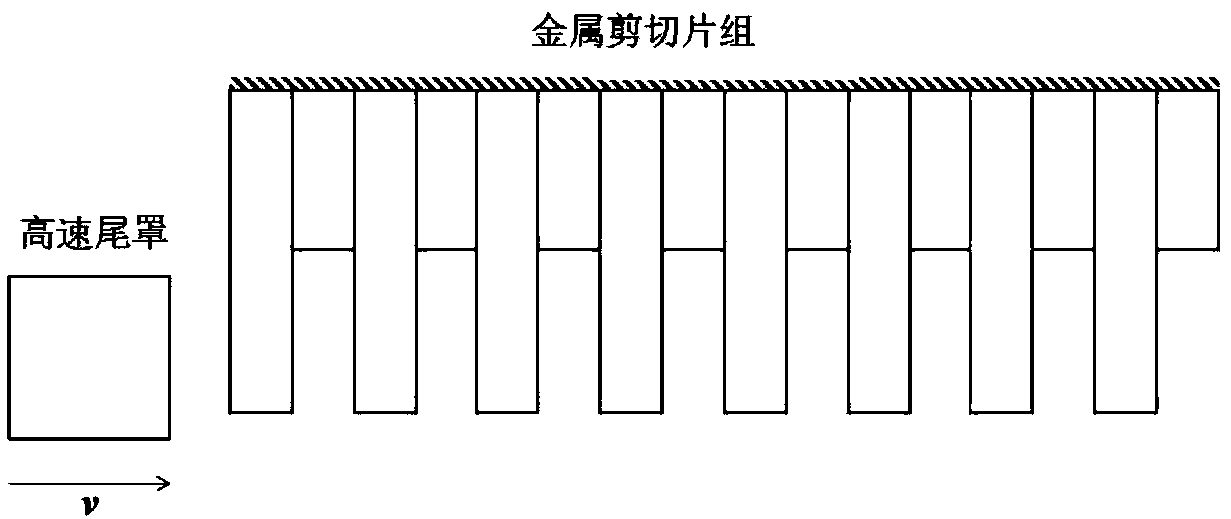

[0025] The present invention provides a stagnation type tail cover separation device based on large impulse collision brake buffer, see attached figure 1 , including: accommodating shell 4, metal shear piece group 5, positioning block 6, force transmission seat 7, positioning pin 8 and limit post 9;

[0026] The overall connection relationship is as follows: see attached figure 2 , the tail cover 2 is installed on the outer circumferential surface of the missile body 1 by the positioning pin 8; the missile body 1 and the tail cover 2 are all installed in the launch tube 3; strip through hole;

[0027] The force transmission seat 7 is a T-shaped structure, and the lower surface of its horizontal part is fitted on the outer circumference of the launch tube 3, and its vertical part passes through the bar-shaped through hole of the launch tube 3 and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com